Preparation method of high-strength transparent nanocellulose paper

A nano-cellulose and transparent technology, applied in special paper, paper, papermaking and other directions, can solve the problems of low strength and poor mechanical properties of transparent paper materials, and achieve improved film-forming properties, light transmittance and optical properties, and condensation. The effect of the glue structure is tight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

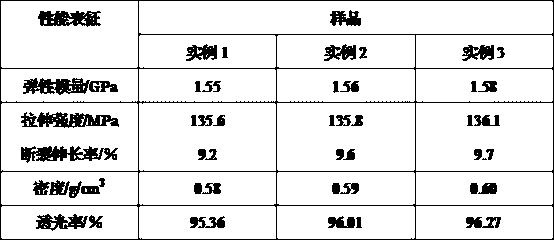

Examples

example 1

[0018] Take moso bamboo and dry it at 85°C for 6 hours, crush it by air flow and pass it through a 200-mesh sieve, collect the sieved moso bamboo powder, and weigh 45 parts of deionized water, 1 part of glacial acetic acid, and 1 part of chlorous acid in parts by weight Sodium and 6 parts of sieved moso bamboo powder were placed in a beaker, heated in a water bath at 70°C for 1 hour, filtered to obtain a filter cake, and vacuum-dried to obtain modified cellulose; take distiller's grains, and mix distiller's grains with deionized water at a mass ratio of 1:10 Mix and place in a centrifuge, centrifuge at 4500r / min for 6min, take the supernatant to obtain distiller's grain extract, mix sieved moso bamboo powder with distiller's grain extract at a mass ratio of 1:10, and seal and ferment at 30°C for 10 days , to obtain the fermented product, filter and collect the filter cake, rinse with 0.1mol / L sodium hydroxide solution for 3 times, then rinse with deionized water for 3 times, an...

example 2

[0020] Take moso bamboo and dry it at 87°C for 7 hours, crush it by air flow and pass it through a 200-mesh sieve, collect the sieved moso bamboo powder, and weigh 47 parts of deionized water, 2 parts of glacial acetic acid, and 2 parts of chlorous acid in parts by weight Sodium and 7 parts of sieved moso bamboo powder were placed in a beaker, heated in a water bath at 72°C for 1 hour, filtered to obtain a filter cake, and vacuum-dried to obtain modified cellulose; take distiller's grains, and mix distiller's grains with deionized water at a mass ratio of 1:10 Mix and place in a centrifuge, centrifuge at 4750r / min for 7 minutes, take the supernatant to obtain distiller's grain extract, mix the sieved moso bamboo powder and distiller's grain extract at a mass ratio of 1:10, and seal and ferment at 30°C for 12 days , to obtain the fermented product, filter and collect the filter cake, rinse with 0.1mol / L sodium hydroxide solution for 4 times, then rinse with deionized water for 4...

example 3

[0022] Take moso bamboo and dry it at 90°C for 8 hours, crush it by airflow and pass it through a 200-mesh sieve, collect the sieved moso bamboo powder, and weigh 50 parts of deionized water, 2 parts of glacial acetic acid, and 2 parts of chlorous acid in parts by weight Sodium and 8 parts of sieved moso bamboo powder were placed in a beaker, heated in a water bath at 75°C for 2 hours, filtered to obtain a filter cake, and vacuum-dried to obtain modified cellulose; take distiller's grains, and mix distiller's grains with deionized water at a mass ratio of 1:10 Mix and place in a centrifuge, centrifuge at 5000r / min for 8 minutes, take the supernatant to obtain distiller's grain extract, mix the sieved moso bamboo powder and distiller's grain extract at a mass ratio of 1:10, and seal and ferment at 30°C for 15 days , to obtain the fermented product, filter and collect the filter cake, rinse with 0.1mol / L sodium hydroxide solution for 5 times, then rinse with deionized water for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com