Pasty thermal-conduction wave-absorbing electromagnetic material and preparation method thereof

An electromagnetic material and a paste-like technology are applied in the field of paste-like heat-conducting and wave-absorbing electromagnetic materials and their preparation, and can solve the problems of inability to achieve good heat dissipation effect, low thermal conductivity and magnetic permeability, poor thermal conductivity and wave-absorbing efficiency, and the like. To achieve the effect of improving the absorbing efficiency, good interface wettability and good absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned pasty heat-conducting and wave-absorbing electromagnetic material comprises the following steps:

[0042] 1) Add insulating and heat-conducting particles, electromagnetic absorbers and additives to the solvent, mix well, react at a constant temperature of 70-90°C for 1-10 hours, filter to remove the solvent, wash and dry the filtered solid to obtain heat-conducting wave-absorbing mixed powder body;

[0043] 2) Mix the silicone oil and the heat-conducting and wave-absorbing mixed powder evenly to obtain a paste;

[0044] 3) Grinding and dispersing the paste, performing densification and defoaming, to obtain a defoaming paste;

[0045] 4) Stir the defoaming paste in a vacuum state for 3-8 hours to obtain a paste-like heat-conducting and wave-absorbing electromagnetic material.

[0046] Preferably, the solvent described in step 1) is toluene, xylene, ethanol, isopropanol, pentane, hexane, octane, ether, propylene oxide, methy...

Embodiment 1

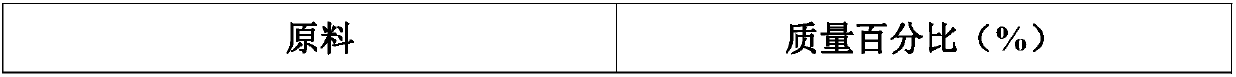

[0051] A paste-like heat-conducting and wave-absorbing electromagnetic material, the raw material composition of which is shown in the following table:

[0052] Table 1 The raw material composition list of a kind of pasty heat-conducting wave-absorbing electromagnetic material

[0053]

[0054]

[0055] The preparation method of the above-mentioned pasty heat-conducting and wave-absorbing electromagnetic material comprises the following steps:

[0056] 1) MgO powder, Fe-Si-Al-Ni alloy powder, dispersant, thickener, stabilizer, coupling agent and polymerization inhibitor are added to absolute ethanol (quality is Fe-Si-Al-Ni alloy powder quality 1.2 times of ), mixed evenly, reacted at a constant temperature of 70°C for 10 hours, filtered to remove absolute ethanol, washed and dried the filtered solid to obtain a heat-conducting and wave-absorbing mixed powder;

[0057] 2) Mix the simethicone oil and the heat-conducting and wave-absorbing mixed powder evenly to obtain a p...

Embodiment 2

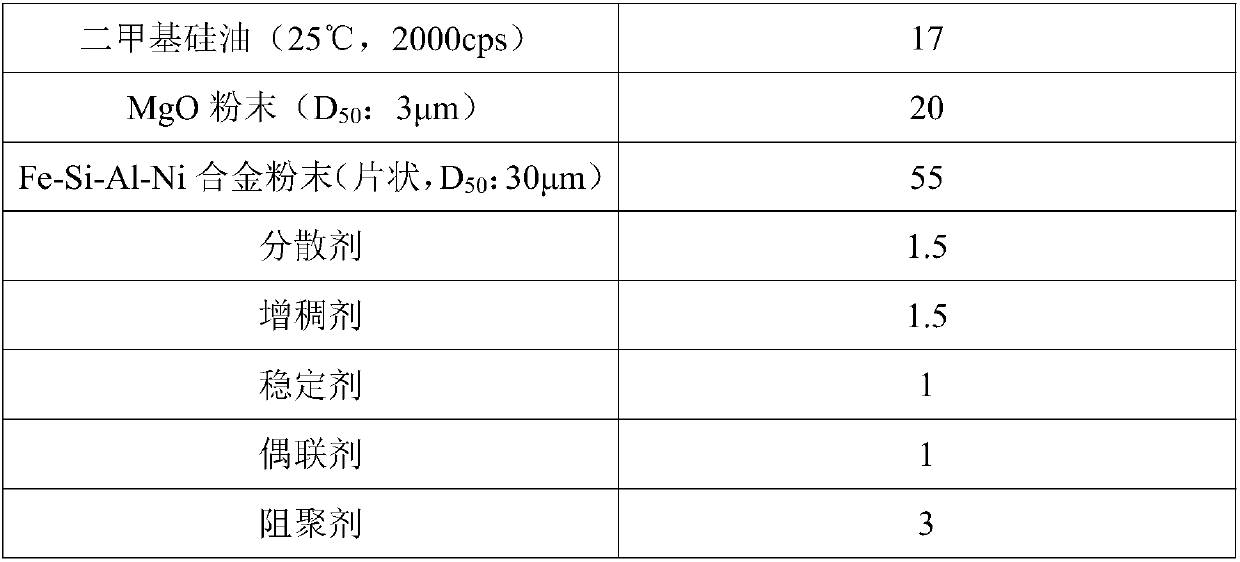

[0061]A paste-like heat-conducting and wave-absorbing electromagnetic material, the raw material composition of which is shown in the following table:

[0062] Table 2 The raw material composition table of a kind of pasty heat-conducting wave-absorbing electromagnetic material

[0063] raw material

Mass percentage (%)

Simethicone oil (25℃, 5000cps)

28

AlN powder (D 50 : 4μm)

5

Permalloy powder (flaky, D 50 : 40μm)

65

Dispersant

1.5

coupling agent

0.5

[0064] The preparation method of the above-mentioned pasty heat-conducting and wave-absorbing electromagnetic material comprises the following steps:

[0065] 1) Add AlN powder, permalloy powder, dispersant and coupling agent to toluene (1.5 times the mass of permalloy powder), mix well, react at a constant temperature of 80°C for 5h, filter to remove toluene, and filter toluene The solid is washed and dried to obtain a heat-conducting and wave-absorbing mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com