AlSi7Mg powder material and preparation method and application thereof

A powder material and powder metallurgy technology, applied in the field of powder materials for metal 3D printing, can solve the problems of low product performance, small output, high impurity content, etc., and achieve the effects of low density, good manufacturability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

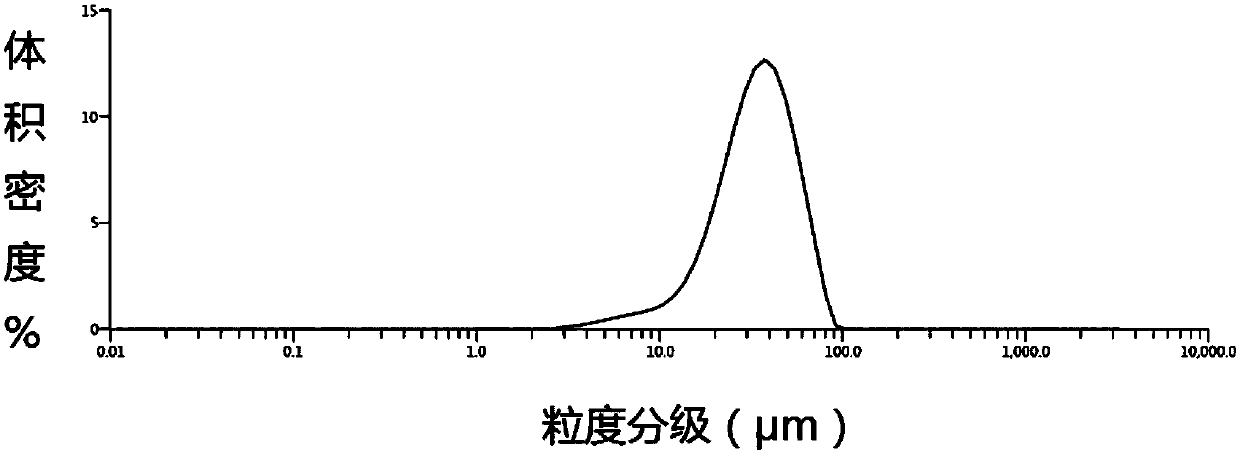

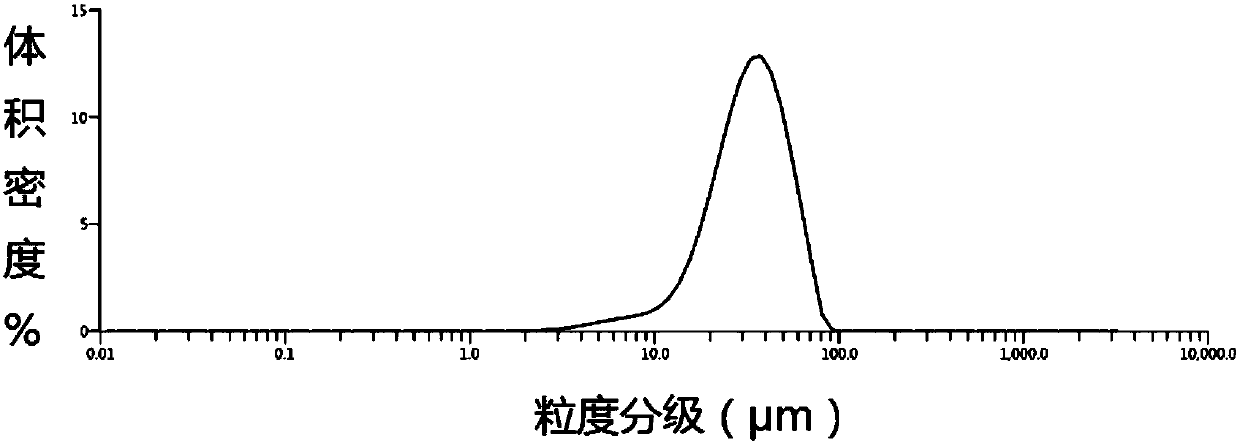

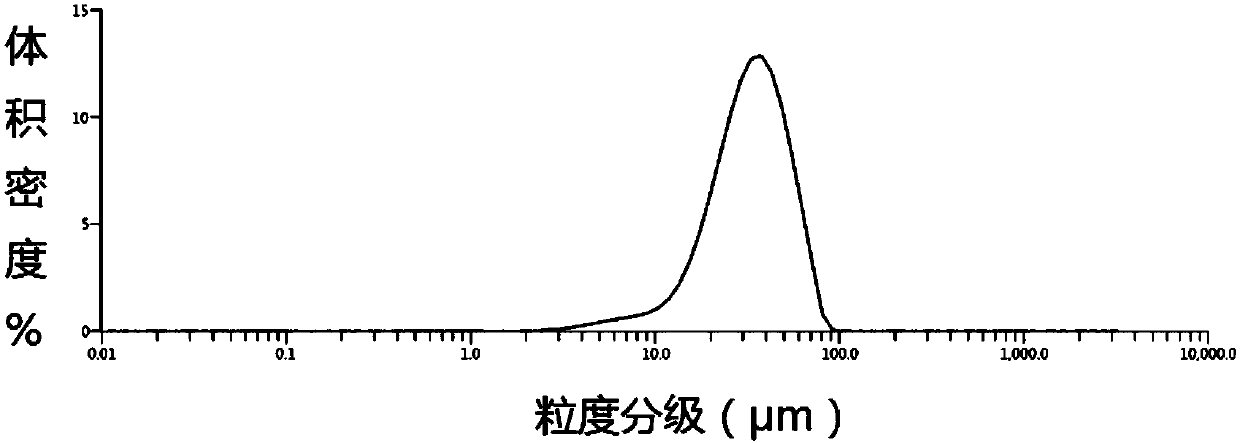

Image

Examples

Embodiment 1-7

[0080] Example 1-7 Preparation of AlSi7Mg powder material

[0081] The preparation of AlSi7Mg powder material by inert gas atomization method includes the following steps:

[0082] (1) Weigh the required amount of raw material aluminum-silicon alloy, aluminum-titanium alloy, aluminum ingot, and magnesium ingot according to Table 1, and place them in the melting crucible;

[0083] (2) After evacuating the melting crucible to a vacuum degree of 2.5 Pa, fill it with argon to a slightly positive pressure;

[0084] (3) Melting aluminum-silicon alloy, aluminum-titanium alloy, refined aluminum ingot, and magnesium ingot into a solution at 800°C, and holding the prepared molten liquid at 750°C for 40 minutes to obtain an alloy molten liquid;

[0085] (4) Pour argon gas into the smelting crucible until its pressure is 2.0 MPa, and atomize the obtained alloy molten liquid;

[0086] (5) After the atomization is over, close the pressure equalizing valve, blow argon into the furnace body to atmosph...

Embodiment 8

[0088] Example 8 Preparation of AlSi7Mg powder material

[0089] The preparation of AlSi7Mg powder material by inert gas atomization method includes the following steps:

[0090] (1) Weigh the required amount of raw material aluminum-silicon alloy, aluminum-titanium alloy, aluminum ingot, and magnesium ingot according to Table 1, and place them in the melting crucible;

[0091] (2) After the smelting crucible is evacuated to its vacuum degree of 3.2 Pa, then nitrogen is filled to atmospheric pressure;

[0092] (3) Melting the aluminum-silicon alloy, aluminum-titanium alloy, refined aluminum ingot, and magnesium ingot into a solution at 850°C, and holding the obtained molten liquid at 800°C for 35 minutes to obtain an alloy molten liquid;

[0093] (4) Pour argon gas into the smelting crucible until its pressure is 2.5MPa, and atomize the obtained alloy molten liquid;

[0094] (5) After the atomization is completed, close the pressure equalizing valve, blow nitrogen into the furnace body...

Embodiment 9

[0096] Example 9 Preparation of AlSi7Mg powder material

[0097] The preparation of AlSi7Mg powder material by inert gas atomization method includes the following steps:

[0098] (1) Weigh the required amount of raw material aluminum-silicon alloy, aluminum-titanium alloy, aluminum ingot, and magnesium ingot according to Table 1, and place them in the melting crucible;

[0099] (2) After evacuating the melting crucible to its vacuum degree of 2.8 Pa, fill it with helium to atmospheric pressure;

[0100] (3) Melting the aluminum-silicon alloy, aluminum-titanium alloy, refined aluminum ingot, and magnesium ingot into a solution at 900°C, and holding the obtained molten liquid at 850°C for 30 minutes to obtain an alloy molten liquid;

[0101] (4) Pour helium into the smelting crucible until its pressure is 2.8MPa, and atomize the obtained alloy molten liquid;

[0102] (5) After the atomization is finished, close the pressure equalizing valve, blow helium into the furnace body to atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com