A kind of silver-based composite solder foil material and preparation method thereof

A technology of silver-based composite and foil materials, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult to use processed welding sheets or welding wires, alloys do not have processability, and alloy plasticity is reduced, so as to achieve good flow The effect of good sex and spreadability, good wettability, and good toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

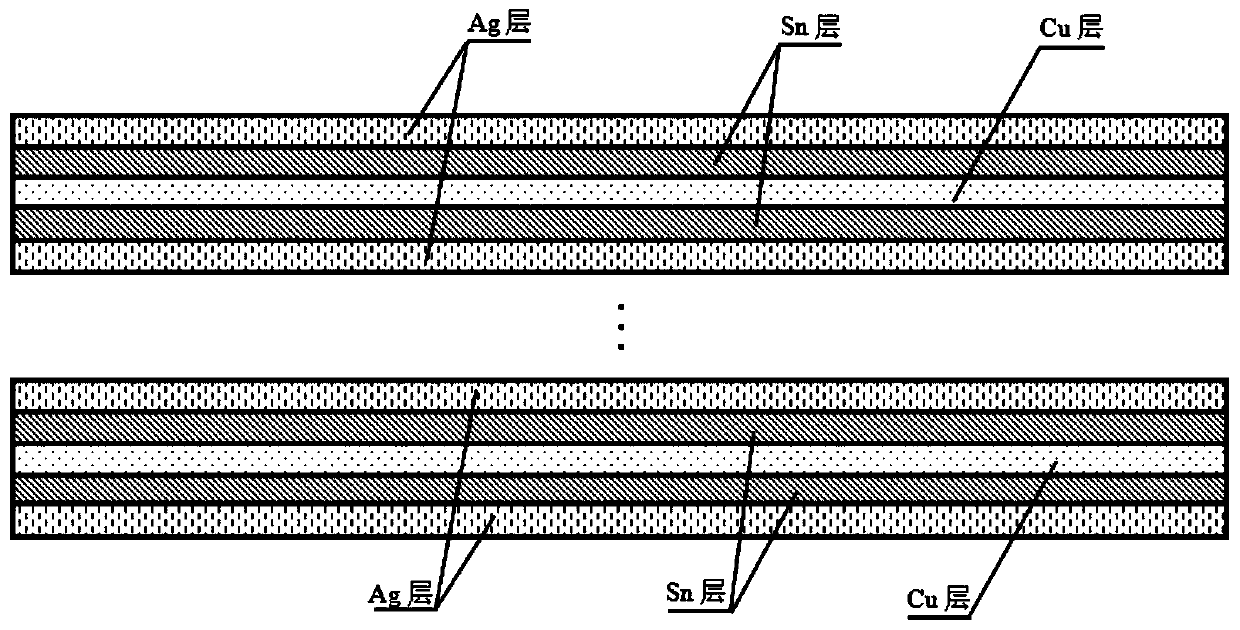

[0021] Using 6 silver layers, 5 copper layers, and 10 tin layers with thicknesses of 0.2, 0.1, and 0.05 mm respectively, a silver-based composite solder foil with a thickness of 0.1 mm was prepared by adopting the steps of the present invention. According to the chemical composition analysis, the weight percentage of the composition of the composite solder foil is: tin content is 20.1%, copper content is 22.2%, and the balance is silver. According to DSC thermal analysis and comparison, the melting temperature range of the silver-based composite solder foil is 28°C narrower than that of the alloy solder prepared by casting method, and the melting point is lowered by 6.8°C. According to GB / T11364-2008 "Experimental Method for Wettability of Solder", the solder wettability test was carried out between the solder prepared by the present invention and the solder prepared by the casting method, that is, 0.05g of each of the two solders was placed in the size The center of the coppe...

Embodiment 2

[0023] Prepare the silver-based composite brazing filler metal foil material by the method of embodiment 1, according to GB / T 11364-2008 " brazing filler metal wettability test method ", the brazing filler metal prepared by the present invention and the brazing filler metal that adopt melting casting method to prepare brazing filler metal Wettability test, that is, place 0.05g of each of the two solders in the center of a nickel substrate of 15×15×2mm, put it into a high vacuum brazing furnace and heat it to 595°C at a heating rate of 20°C / min and keep it for 5min. Then cool down to room temperature with the furnace, after measuring, it is found that the wetted area of the silver-based composite solder foil prepared by the method of the present invention is 1.1 times that of the solder wetted area prepared by the melting and casting method to the nickel base material. The wettability of the solder to the nickel substrate is better. Under the same brazing conditions, nickel s...

Embodiment 3

[0025] Silver-based composite solder foil was prepared according to the method of Example 1. Under the same brazing conditions, the lap joint test of copper and nickel substrates was carried out on the two solders. The length of the lap joint was 2 mm, and the gap between the welds was 0.1 mm. According to GB / T 228.1-2010 "Metal Material Tensile Test", the mechanical properties of the welded joints are tested and compared, and it is found that the silver-based composite solder foil prepared by the method of the present invention is used to braze copper and nickel substrates. The tensile strength of the brazed joint is 10.6MPa higher than that of the solder prepared by the melting and casting method, and the silver-based composite solder foil prepared by the method of the present invention can be used to braze copper and nickel substrates with better mechanical properties. Brazed joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com