Method for grafting functional cellulose onto zeolite and waste water treatment method

A technology for grafting zeolite and cellulose, which is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. The membrane is easy to block and other problems, so that the grafting process is simple and easy to implement, large-scale application is achieved, and the pore size is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

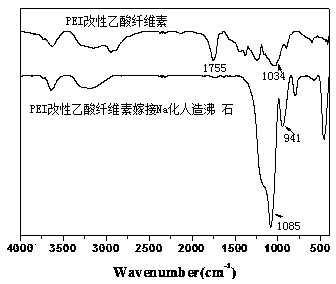

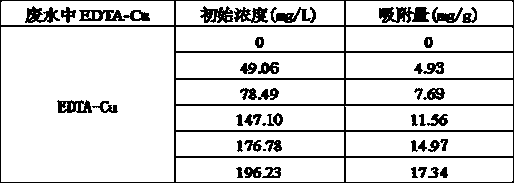

Method used

Image

Examples

Embodiment 1

[0049] The method for grafting zeolite with functionalized cellulose of the present invention comprises the following steps:

[0050] 1) Accurately weigh 35.06g of NaCl and dissolve it in 2L of distilled water, stir and dissolve to obtain a NaCl solution with a concentration of 0.3mol / L;

[0051]2) Add 20 g of artificial zeolite that has passed through a 200-mesh sieve into the NaCl solution in step 1), heat and stir at 100°C for 3 hours, centrifuge, wash with distilled water until neutral, and dry to obtain Na-modified artificial zeolite;

[0052] 3) Take 8g of cellulose acetate I and disperse it in 400mL of methanol, then add 40g of polyethyleneimine, stir for 24 hours, mix well and then centrifuge immediately to remove excess polyethyleneimine to obtain polyethyleneimine-coated cellulose acetate II;

[0053] 4) Add the cellulose acetate II obtained in step 3) into 400 mL of distilled water, then slowly add 12 mL of 25% glutaraldehyde aqueous solution, and adjust the pH of ...

Embodiment 2

[0058] The method for grafting zeolite with functionalized cellulose of the present invention comprises the following steps:

[0059] 1) Accurately weigh 11.69g of NaCl and dissolve it in 2L of distilled water, stir and dissolve to obtain a NaCl solution with a concentration of 0.1mol / L;

[0060] 2) Add 30 g of artificial zeolite that has passed through a 200-mesh sieve into the NaCl solution in step 1), heat and stir at 120°C for 4 hours, centrifuge, wash with distilled water until neutral, and dry to obtain Na-modified artificial zeolite;

[0061] 3) Take 4g of cellulose acetate I and disperse it in 200mL of methanol, then add 20g of polyethyleneimine, stir for 48h, make it fully mixed and then centrifuge immediately to remove excess polyethyleneimine to obtain polyethyleneimine-coated cellulose acetate II;

[0062] 4) Add the cellulose acetate II obtained in step 3) into 200 mL of distilled water, then slowly add 8 mL of 25% glutaraldehyde aqueous solution, and adjust the ...

Embodiment 3

[0067] The method for grafting zeolite with functionalized cellulose of the present invention comprises the following steps:

[0068] 1) Accurately weigh 58.44g NaCl and dissolve it in 2L distilled water, stir and dissolve to obtain a NaCl solution with a concentration of 0.5mol / L;

[0069] 2) Add 40 g of artificial zeolite that has passed through a 200-mesh sieve to the NaCl solution in step 1), heat and stir at 80°C for 5 hours, centrifuge, wash with distilled water until neutral, and dry to obtain Na-modified artificial zeolite;

[0070] 3) Take 6g of cellulose acetate I and disperse it in 300mL of methanol, then add 30g of polyethyleneimine, stir for 36 hours, mix well and then centrifuge immediately to remove excess polyethyleneimine to obtain polyethyleneimine-coated cellulose acetate II;

[0071] 4) Add the cellulose acetate II obtained in step 3) into 300mL of distilled water, then slowly add 10mL of 25% glutaraldehyde aqueous solution, and adjust the pH of the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com