Ampicillin capsule and preparation method thereof

A technology of ampicillin capsules and ampicillin, which can be used in capsule delivery, pharmaceutical formulations, antibacterial drugs, etc., can solve problems such as poor bioavailability and slow onset of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An ampicillin capsule, the drug-containing granules are made of the following raw materials in the weight ratio: 3g of ampicillin, 1g of cellulose acetate phthalate, 0.5g of rye starch with a water content of 10.5%, and ethanol with a concentration of 25%. 0.5g, sterile water 5g.

[0024] A preparation method for ampicillin capsules, comprising the steps of:

[0025] (1) Get ampicillin and carry out pulverization process by supersonic air flow, action time is 8min, makes ultrafine ampicillin particle;

[0026] (2) Take cellulose acetate phthalate and superfine ampicillin particles and dissolve them in sterile water, and perform ultrasonic treatment for 25s to prepare suspension A;

[0027] (3) Add dry starch to suspension A, ultrasonicate for 45 seconds, heat in a water bath at 60°C for 20 minutes, and cool to room temperature to obtain suspension B;

[0028] (4) Add ethanol to the suspension B, mix uniformly, and dry in vacuum to obtain a drug solid;

[0029] (5) Tr...

Embodiment 2

[0032] An ampicillin capsule, the drug-containing granules are made of the following raw materials in the weight ratio: 4 g of ampicillin, 1.2 g of cellulose acetate phthalate, 0.6 g of rye starch with a water content of 10.5%, and 25% cellulose acetate Ethanol 0.5g, sterile water 7g.

[0033] The preparation steps are the same as in Example 1.

Embodiment 3

[0035] An ampicillin capsule, the drug-containing granules are made of the following raw materials in the weight ratio: 5 g of ampicillin, 1.5 g of cellulose acetate phthalate, 0.7 g of rye starch with a water content of 11.5%, and 25% cellulose acetate Ethanol 0.5g, sterile water 10g.

[0036] The preparation steps are the same as in Example 1.

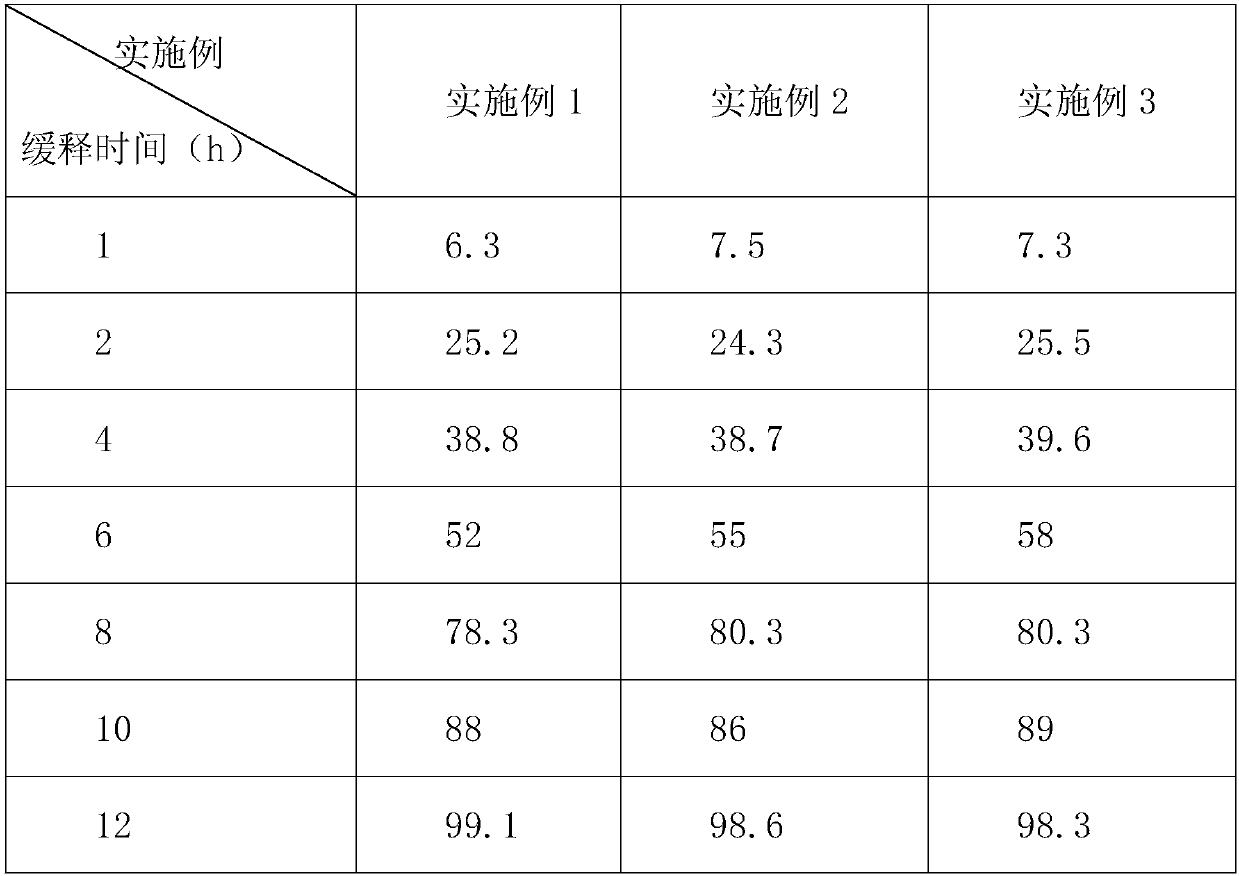

[0037] Get 3 groups of ampicillin capsule samples, according to release assay method (Chinese Pharmacopoeia edition in 2000 two appendix XD first method) (adopt the device of dissolution assay second method), with pH7.4 phosphate buffer saline 1000mL as solvent , the rotation speed is 200 revolutions per minute, operate according to the law, take 10mL of the solution at the first hour, 2 hours, 4 hours, 6 hours, 8 hours, 10 hours, and 12 hours, filter, and immediately add pH7. 4 Phosphate buffer 10mL as the test solution. According to spectrophotometry (Appendix IVA of Chinese Pharmacopoeia 2000 Edition), the absorbance value was m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com