High viscosity phenyl methyl silicone oil and preparing method thereof

A technology of phenylmethyl silicone oil and high viscosity, which is applied in the field of phenylmethyl silicone oil and its preparation, can solve the problem that high-viscosity phenylmethyl silicone oil is not suitable for use, and cannot prepare high-viscosity phenylmethyl silicone oil, viscosity Problems such as poor control technology are achieved to achieve low cost, high phenyl content, and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

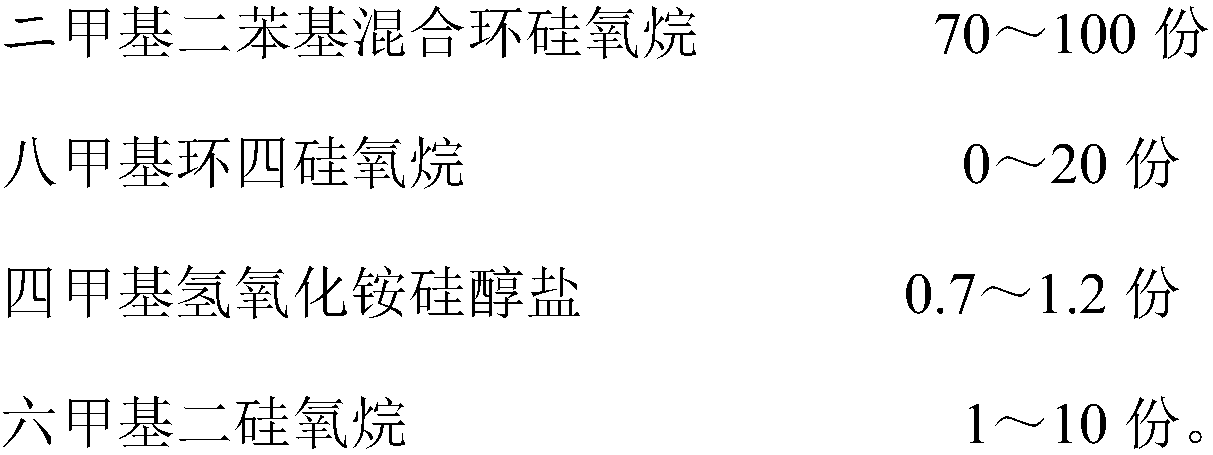

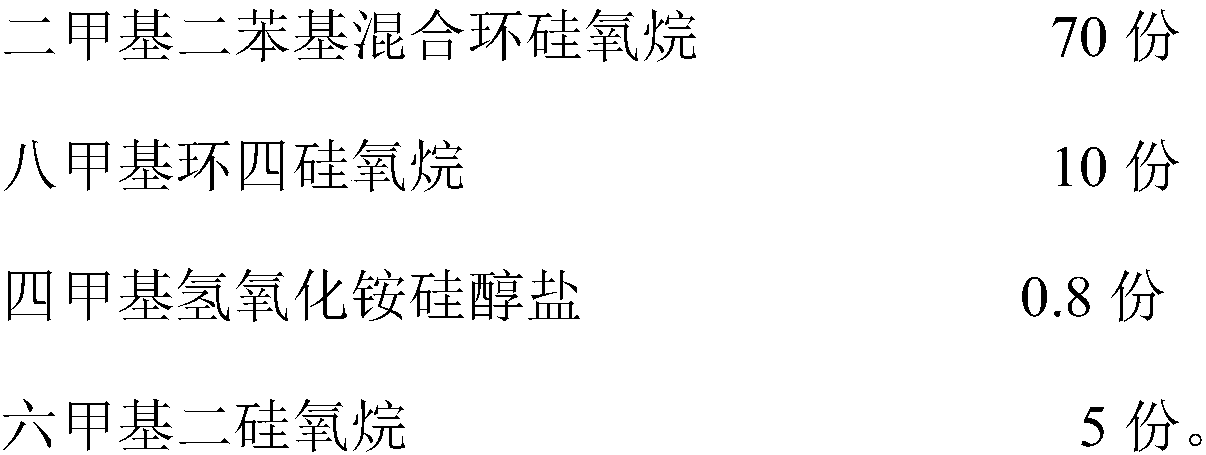

[0037] formula:

[0038]

[0039] Add dimethyldiphenyl mixed cyclosiloxane and octamethylcyclotetrasiloxane into the reactor, mix and dehydrate for 1 hour at 40°C and -0.09MPa.

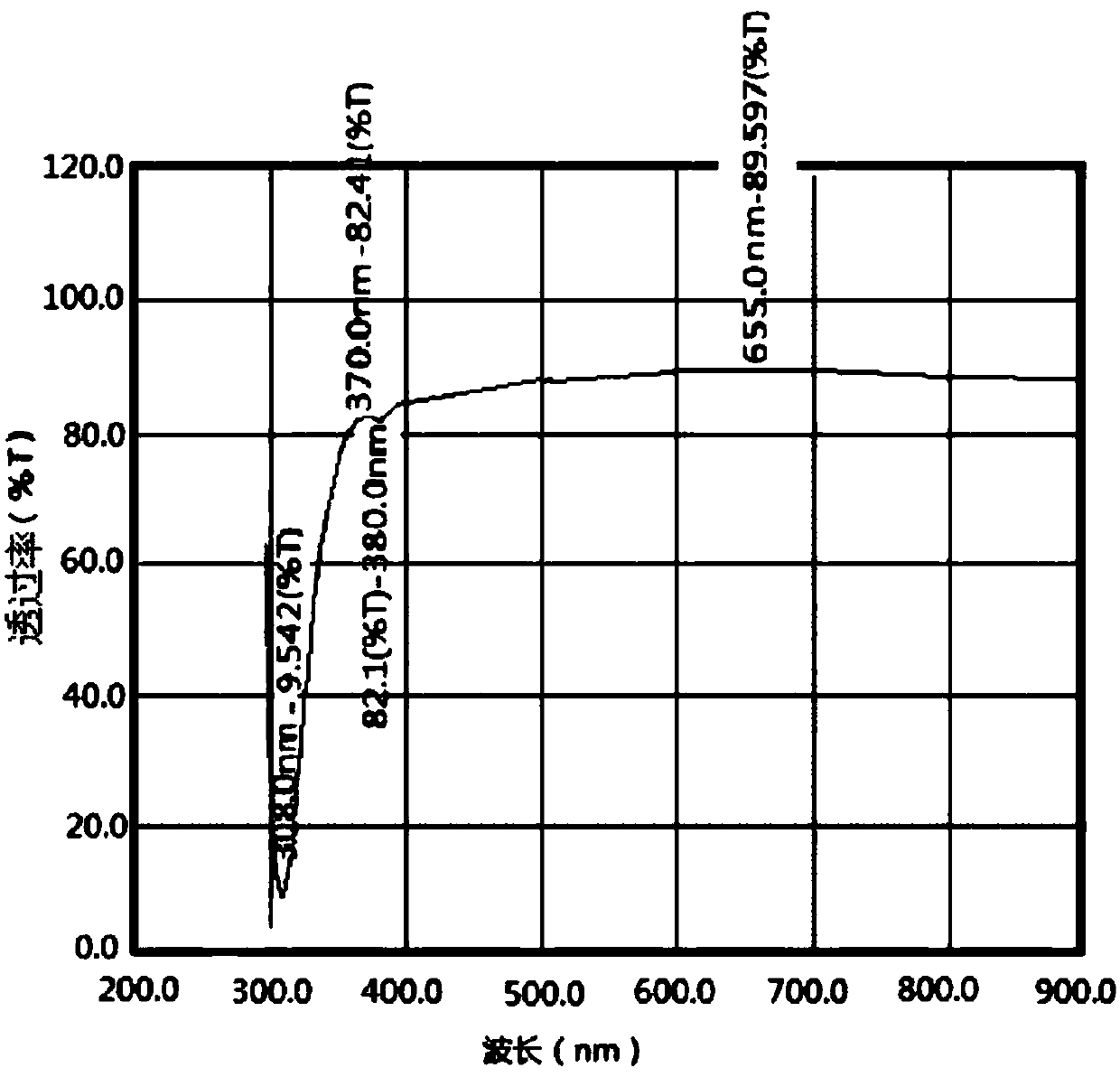

[0040] After the dehydration is completed, the temperature of the reaction system is raised to 90°C, tetramethylammonium hydroxide silicon alkoxide is added, and the reaction is carried out at -0.09MPa. When the viscosity of the system increases rapidly, add 5 parts of hexamethyldisiloxane, and continue to react for 2 hours under normal pressure and 90°C. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (inactivate) tetramethylammonium hydroxide silicon alkoxide for 30 minutes. Then the temperature of the reaction system was raised to 180°C, and the pressure was reduced to -0.09MPa to remove small molecular compounds for 30 minutes to obtain high-viscosity phenylmethyl silicone oil. After measurement, the product has a refractive index of 1.4959, a vis...

Embodiment 2

[0043] formula:

[0044]

[0045] 100 parts of dimethyldiphenyl mixed cyclosiloxane was added to the reactor, and dehydration was carried out at 30°C and -0.09MPa for 2 hours.

[0046] After the dehydration is complete, the temperature of the reaction system is raised to 80°C, 1 part of tetramethylammonium hydroxide silicon alkoxide is added, and the reaction is carried out at -0.09MPa. When the viscosity of the system increases rapidly, add 10 parts of hexamethyldisiloxane, and continue to react for 3 hours at normal pressure and 80°C. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (deactivate) tetramethylammonium hydroxide silicon alkoxide for 35 minutes. Then the temperature of the reaction system was raised to 175°C, and the pressure was reduced to -0.09MPa to remove small molecular compounds for 35 minutes to obtain high-viscosity phenylmethyl silicone oil. After measurement, the refractive index is 1.4984 and the viscos...

Embodiment 3

[0048] formula:

[0049]

[0050] Add 100 parts of dimethyldiphenyl mixed cyclosiloxane and 20 parts of octamethylcyclotetrasiloxane into the reactor, mix and dehydrate for 1.5 hours at 35°C and -0.09MPa.

[0051] After dehydration is complete, the temperature of the reaction system is raised to 85°C, 1.2 parts of tetramethylammonium hydroxide silicon alkoxide is added, and the reaction is carried out at -0.09MPa. When the viscosity of the system increases rapidly, add 5 parts of hexamethyldisiloxane, and continue to react at normal pressure and 85°C for 2 hours. After the reaction, the temperature of the reaction system was raised to 150° C. to decompose (deactivate) tetramethylammonium hydroxide silicon alkoxide for 40 minutes. Then the temperature of the reaction system was raised to 170°C, and the small molecule compounds were removed for 40 minutes under the condition of reducing the pressure to -0.09MPa to obtain high-viscosity phenylmethyl silicone oil. After measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com