Preparation method of high-temperature-resistant anti-static type release film

A technology of anti-static and release film, which is applied in the field of preparation of high-temperature resistant anti-static release film, can solve the problems of not being able to meet market requirements, poor high-temperature resistance, and poor anti-static performance, and achieve good heat resistance and high temperature resistance Improved performance and improved antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

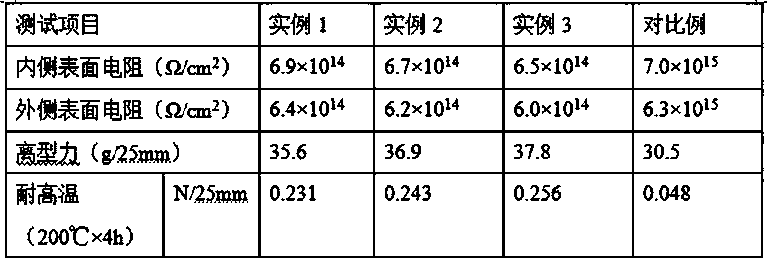

Examples

example 1

[0022] Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a beaker at a volume ratio of 1:4:2, stir for 10 minutes at a temperature of 35°C to obtain a stirring liquid, and then add the stirring liquid to the beaker dropwise 3% by volume of hydrochloric acid with a mass fraction of 20%, continue to insulate and mix and stir for 18 minutes to obtain a reaction solution, put the reaction solution into an ultrasonic oscillator for ultrasonic oscillation for 20 minutes, leave it to age for 1 day, and discharge the material to obtain a self-made silica sol ;According to the mass ratio of 3:1:1, mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin for 16 minutes, heat up to 120°C to obtain a mixed resin, and then mix the mixed resin and The mass ratio of homemade silica sol is 2:1. Continue to keep warm and mix and stir for 45 minutes to obtain the modified epoxy resin; weigh 24g of graphite and grind it for 10 minutes and pass it through an 8...

example 2

[0024]Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a beaker at a volume ratio of 1:4:2, and stir for 11 minutes at a temperature of 40°C to obtain a stirring liquid, and then add the stirring liquid to the beaker dropwise 3% by volume of hydrochloric acid with a mass fraction of 20%, continue to insulate and mix and stir for 22 minutes to obtain a reaction solution, put the reaction solution into an ultrasonic oscillator for ultrasonic oscillation for 25 minutes, leave it to stand and age for 1.5 days, and discharge to obtain self-made silica sol ;According to the mass ratio of 3:1:1, mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin for 18 minutes, heat up to 140°C to obtain a mixed resin, and then mix the mixed resin and The mass ratio of self-made silica sol is 2:1, continue to keep warm and mix and stir for 55 minutes, and obtain the modified epoxy resin; weigh 28g of graphite and grind it for 11 minutes, pass through an 80-...

example 3

[0026] Mix deionized water, tetraethyl orthosilicate and absolute ethanol in a beaker at a volume ratio of 1:4:2, stir for 12 minutes at a temperature of 45°C to obtain a stirring liquid, and then add the stirring liquid to the beaker dropwise 3% by volume of hydrochloric acid with a mass fraction of 20%, continue to insulate and mix and stir for 24 minutes to obtain a reaction solution, put the reaction solution into an ultrasonic oscillator for ultrasonic oscillation for 30 minutes, leave it to stand and age for 2 days, and discharge the material to obtain a self-made silica sol ;According to the mass ratio of 3:1:1, mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin for 20 minutes, heat up to 160°C to obtain a mixed resin, and then mix the mixed resin and The mass ratio of homemade silica sol is 2:1, and the heat preservation and mixing are continued for 60 minutes to obtain the modified epoxy resin; 32g of graphite is weighed and ground for 12 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com