Preparation method of ultra-long lifetime nickel-hydrogen battery electrode material

A nickel-metal hydride battery and electrode material technology, which is applied in the direction of primary battery electrodes, alkaline storage battery electrodes, electrode manufacturing, etc., can solve problems such as inability to fully meet the needs of the future power vehicle market, high and low replacement battery costs, and electrode structure damage. , to achieve the effects of inhibiting the formation of dendrites, improving the utilization rate, and increasing the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

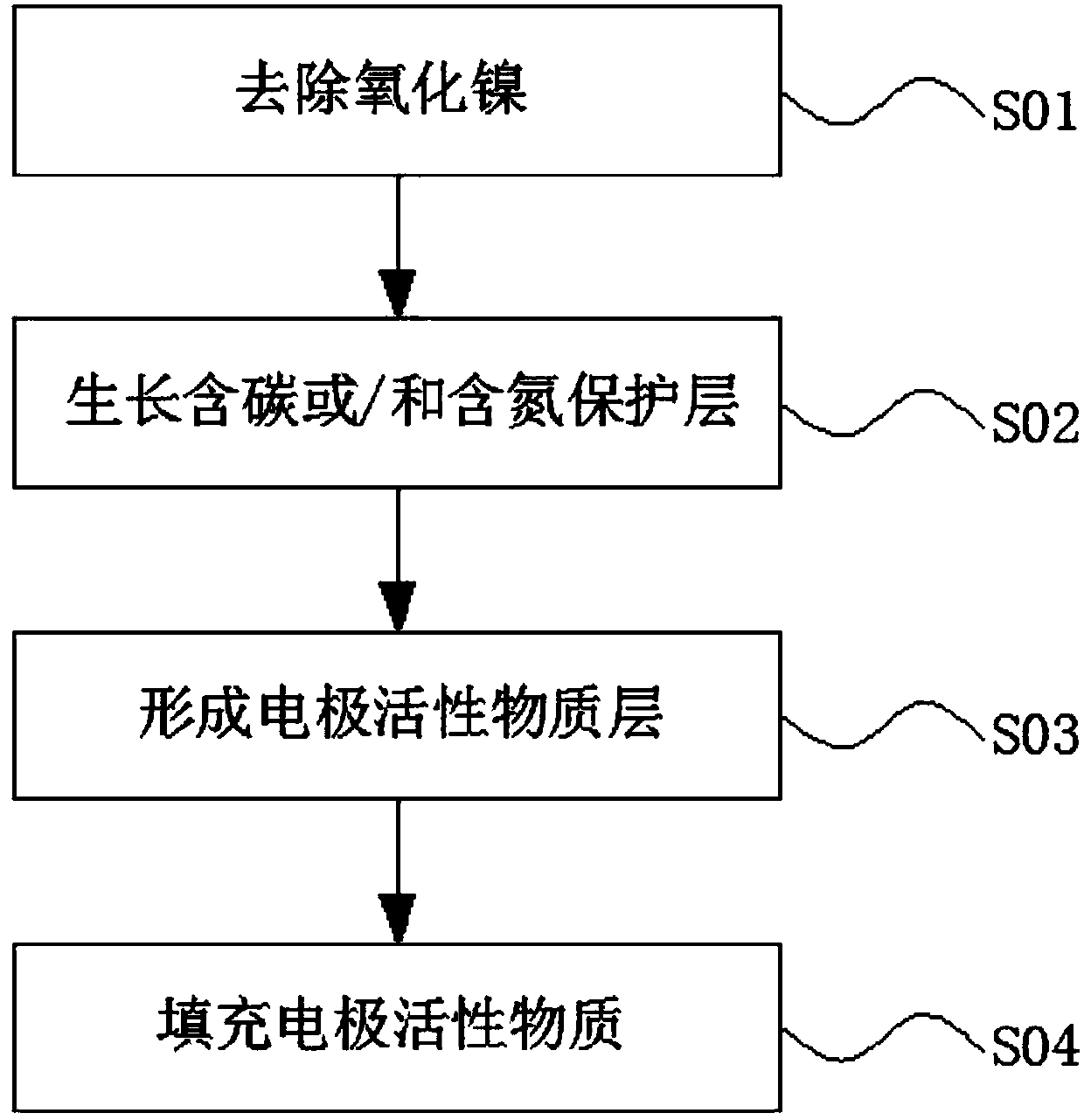

[0023] The invention provides a method for preparing an electrode material for an ultra-long-life nickel-metal hydride battery, the method comprising the following steps:

[0024] S01, remove the nickel oxide on the surface of the foamed nickel pore wall, adopt at least one of hydrogen reduction or acid treatment methods, the foamed nickel is the conductive skeleton of the positive electrode or / and negative electrode material, and its surface density is 200-400g / m2, porosity ≥95%, the thickness is 1-3mm;

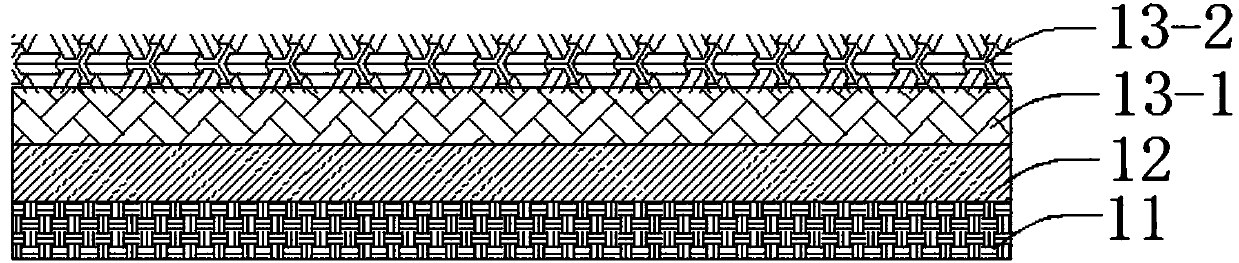

[0025] S02, grow a layer of carbon-containing or / and nitrogen-containing protective layer on the surface of the nickel foam cell wall, the preparation method adopted is chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), and water At least one of the thermochemical reaction methods, the carbon or / and nitrogen-containing protective layer is highly conductive, the surface contains many dangling bonds and active hydroxyl groups, effe...

Embodiment 1

[0030] First, the nickel oxide layer on the surface of the nickel foam cell wall was removed by hydrogen reduction, and then a carbon / nitrogen-containing protective layer with a thickness of about 500 nm was formed on the surface of the nickel foam by atomic layer deposition (ALD). Electroless deposition method immerses positive electrode active material Ni(OH) 2 solution, forming a uniform layer of Ni(OH) on its surface 2 layer, and finally the active material Ni(OH) 2 Fill the pores of nickel foam and roll to form the positive electrode of nickel-metal hydride batteries. The negative electrode of Ni-MH battery adopts conventional steel mesh, or copper mesh + metal hydride (LaNi 5 h 6 ) made, and finally assembled into a nickel metal hydride battery.

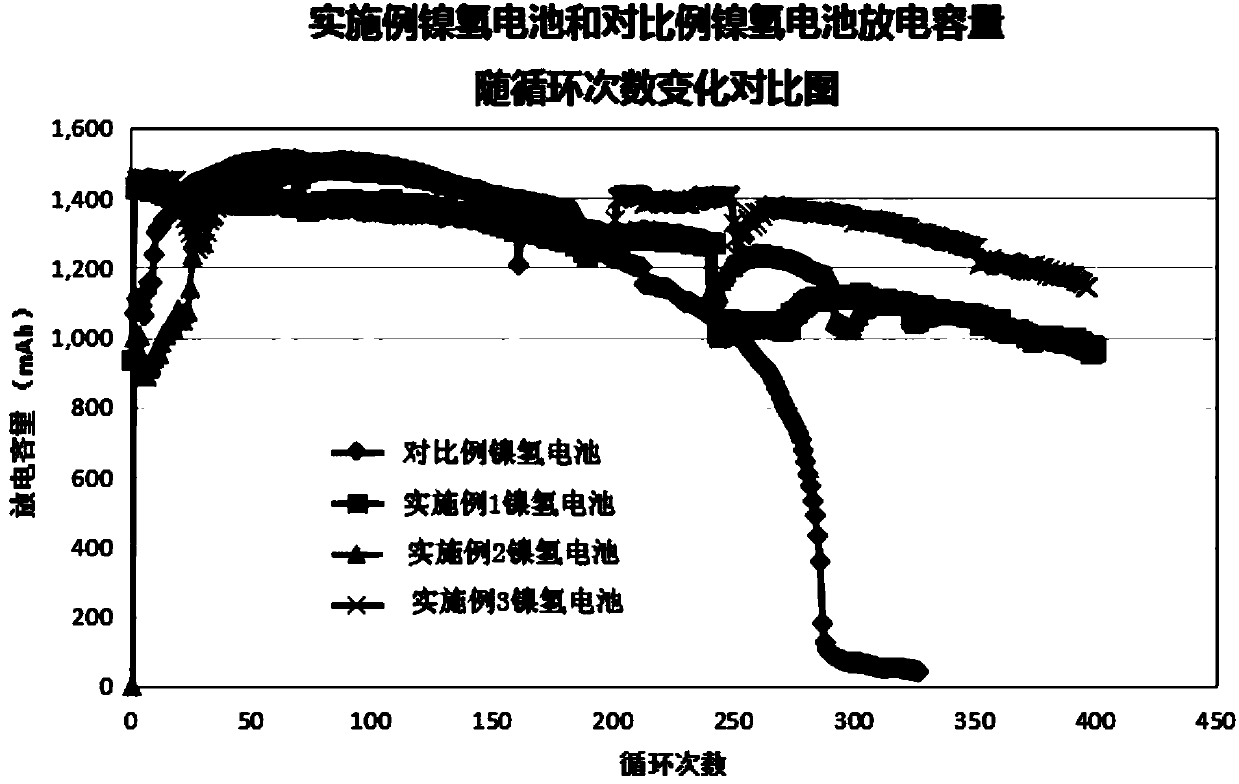

[0031] The nickel-metal hydride battery is charged and discharged at 1C, and its discharge capacity is about 1500mAh. After 400 cycles, it still maintains a capacity of about 950mAh, and the capacity still maintains about 6...

Embodiment 2

[0033] The nickel oxide layer on the surface of the foamed nickel pore wall is removed by acid treatment, and a carbon / nitrogen-containing protective layer with a thickness of about 100nm is formed on the foamed nickel surface by chemical vapor deposition (CVD), and then electrochemical deposition is used. The method is to immerse the positive electrode active material Ni(OH) 2 solution, forming a uniform layer of Ni(OH) on its surface 2 layer, and finally the active material Ni(OH) 2 Fill the pores of nickel foam and roll to form the positive electrode of nickel-metal hydride batteries. The negative electrode of Ni-MH battery adopts conventional steel mesh, or copper mesh + metal hydride (LaNi 5 h 6 ) made, and finally assembled into a nickel metal hydride battery.

[0034] The nickel-metal hydride battery is charged and discharged at 1C, and its discharge capacity is about 1500mAh. After 400 cycles, it still maintains a capacity of about 950mAh, and the capacity still ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com