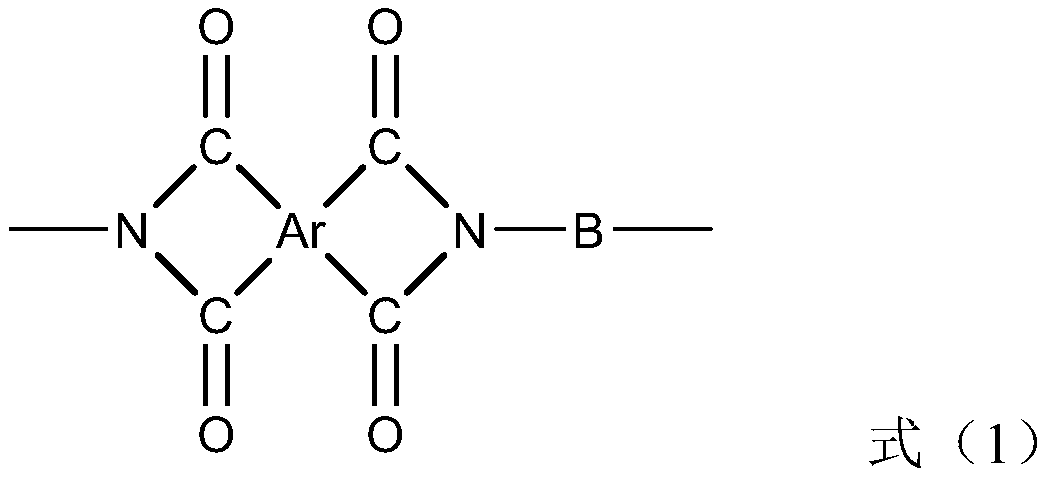

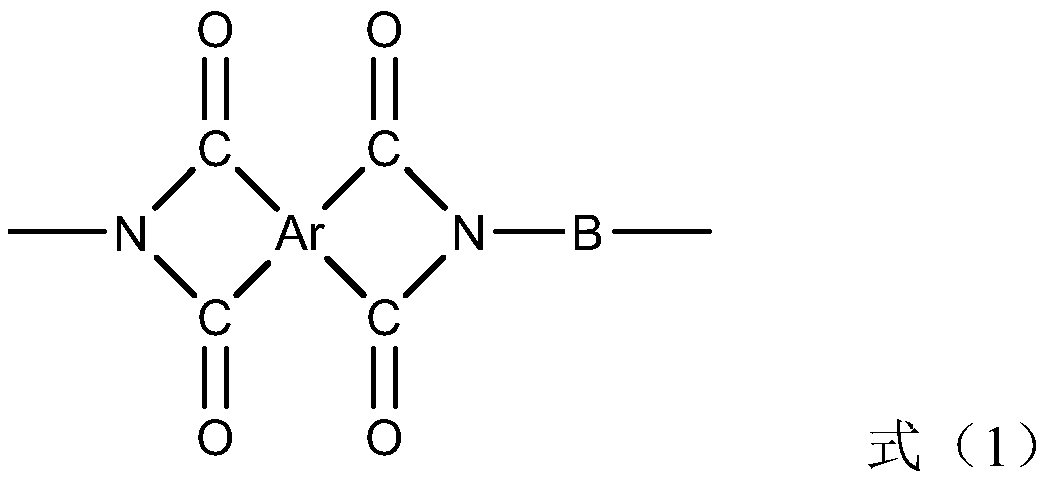

A kind of polyimide hollow fiber and its preparation method and application

A technology of polyimide and liquid polyamic acid, which is applied in the field of high-performance membrane separation, can solve problems such as poor separation effect, and achieve outstanding mechanical properties and operating pressure, excellent medium corrosion resistance, and good permeation and separation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This example is used to illustrate the polyimide hollow fiber of the present invention and its preparation method.

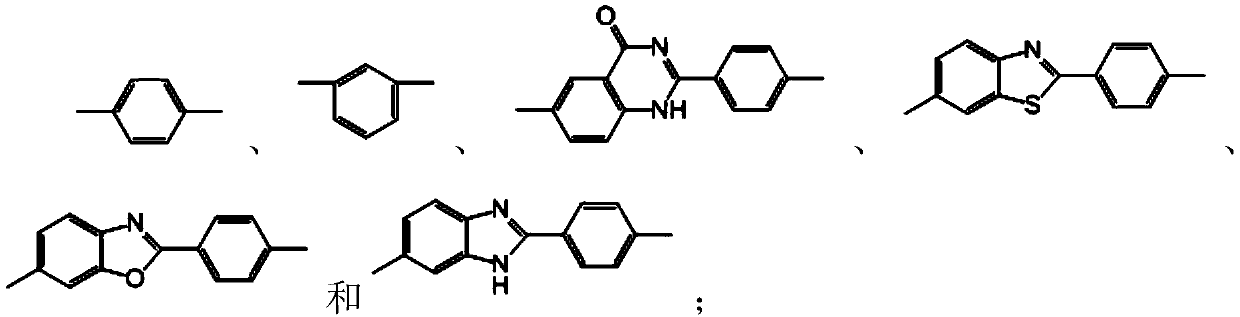

[0075](1) Select NMP as solvent, get biphenyl tetracarboxylic dianhydride (BPDA), benzophenone tetracarboxylic dianhydride (BTDA), p-phenylenediamine (p-PDA), quinazolinone diamine by 1: The molar ratio of 0.5:1:0.5 is reacted at 25 ℃ for 3h to prepare spinning solution polyamic acid, and adjust the solid content of the spinning solution polyamic acid obtained in step (1) to 20% by weight, and the solid content is 20% by weight The rotational viscosity of polyamic acid in the spinning solution is 50Pa·s, and the intrinsic viscosity is 2.5dl / g;

[0076] (2) The spinning liquid polyamic acid and the spinning core liquid obtained in step (1) are extruded by a dry-jet wet spinning method and immersed in a coagulation bath to solidify to obtain a polyamic acid hollow fiber, wherein , the temperature of the coagulation bath is 0°C, the distance between the spi...

Embodiment 2

[0084] This example is used to illustrate the polyimide hollow fiber of the present invention and its preparation method.

[0085] (1) Select dimethylacetamide as solvent, take biphenyltetracarboxylic dianhydride (BPDA), benzophenone tetracarboxylic dianhydride (BTDA), p-phenylenediamine (p-PDA), quinazolinone two The amine was reacted at 25°C for 3h at a molar ratio of 1:0.1:1:0.1 to prepare the spinning solution polyamic acid, and the solid content of the spinning solution polyamic acid obtained in step (1) was adjusted to 15% by weight, and the solid content The rotational viscosity of polyamic acid that is 15% by weight of the spinning solution is 20Pa·s, and the intrinsic viscosity is 2.0dl / g;

[0086] (2) The spinning liquid polyamic acid and the spinning core liquid obtained in step (1) are extruded by a dry-jet wet spinning method and immersed in a coagulation bath to solidify to obtain a polyamic acid hollow fiber, wherein , the temperature of the coagulation bath is...

Embodiment 3

[0094] This example is used to illustrate the polyimide hollow fiber of the present invention and its preparation method.

[0095] (1) Select dimethylformamide as solvent, take biphenyltetracarboxylic dianhydride (BPDA), benzophenone tetracarboxylic dianhydride (BTDA), p-phenylenediamine (p-PDA), quinazolinone two Amine was reacted at 25°C for 3h at a molar ratio of 1:0.1:0.7:0.4 to prepare spinning solution polyamic acid, and the solid content of the spinning solution polyamic acid obtained in step (1) was adjusted to 18% by weight, and the solid content The rotational viscosity of polyamic acid to 18% by weight of the spinning solution is 40Pa·s, and the intrinsic viscosity is 2.5dl / g;

[0096] (2) The spinning liquid polyamic acid and the spinning core liquid obtained in step (1) are extruded by a dry-jet wet spinning method and immersed in a coagulation bath to solidify to obtain a polyamic acid hollow fiber, wherein , the temperature of the coagulation bath is 25°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com