Flower-like hierarchical nitrogen-doped porous carbon-selenium composite positive electrode material and preparation method and application of such material

A composite positive electrode material and porous carbon material technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of prominent shuttle effect, complex process, low selenium loading, etc., to improve stability and electrochemical performance, The process is simple and the effect of reducing the cost of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A nitrogen-doped flower-like hierarchical structure porous carbon material, the preparation method of which is as follows:

[0048] 1) Disperse 8.1g zinc acetate dihydrate and 4g P123 in 100ml deionized water, add 2.3g sodium glutamate under stirring condition, stir and react for 30min, the resulting product is washed 5 times with deionized water and ethanol respectively, and in Dry overnight in an oven at 60°C to obtain the precursor zinc glutamic acid;

[0049]2) Put the precursor zinc glutamate obtained in step 1) in a tube furnace, and in an argon atmosphere, raise the temperature to 100°C at a rate of 2°C / min and keep it for 120min, then raise the temperature to 400°C and keep it for 120min, and finally raise the temperature Keep warm at 800°C for 300 minutes, then cool naturally to room temperature with the furnace to obtain solid powder;

[0050] 3) Soak the solid powder obtained in step 2) in 2 mol of hydrochloric acid for 12 hours, then perform suction filtrat...

Embodiment 2

[0053] A nitrogen-doped flower-like hierarchical structure porous carbon material, the preparation method of which is as follows:

[0054] 1) Disperse 10.8g zinc acetate dihydrate and 5g P123 in 100ml deionized water, add 2.3g sodium glutamate under stirring condition, stir and react for 30min, the resulting product is washed 5 times with deionized water and ethanol respectively, and in Dry overnight in an oven at 60°C to obtain the precursor zinc glutamic acid;

[0055] 2) Place the precursor zinc glutamate obtained in step 1) in a tube furnace, and in an argon atmosphere, raise the temperature to 200°C at a rate of 5°C / min and keep it for 100 minutes, then raise the temperature to 500°C and keep it for 100 minutes, and finally raise the temperature Keep warm at 900°C for 400 minutes, then cool naturally to room temperature with the furnace to obtain solid powder;

[0056] 3) Soak the solid powder obtained in step 2) in 3 mol of hydrochloric acid for 24 hours, then perform s...

Embodiment 3

[0059] A nitrogen-doped flower-like hierarchical structure porous carbon material, the preparation method of which is as follows:

[0060] 1) Disperse 13.5g zinc acetate dihydrate and 6g P123 in 100ml deionized water, add 2.3g sodium glutamate under stirring condition, stir and react for 30min, the resulting product is washed 5 times with deionized water and ethanol respectively, and in Dry overnight in an oven at 60°C to obtain the precursor zinc glutamic acid;

[0061] 2) Put the precursor zinc glutamate obtained in step 1) in a tube furnace, and in an argon atmosphere, raise the temperature to 200°C at a rate of 5°C / min and keep it for 200 minutes, then raise the temperature to 500°C and keep it for 200 minutes, and finally raise the temperature Keep warm at 800°C for 400 minutes, then cool naturally to room temperature with the furnace to obtain solid powder;

[0062] 3) Soak the solid powder obtained in step 2) in 4 mol of hydrochloric acid for 12 hours, then perform suc...

PUM

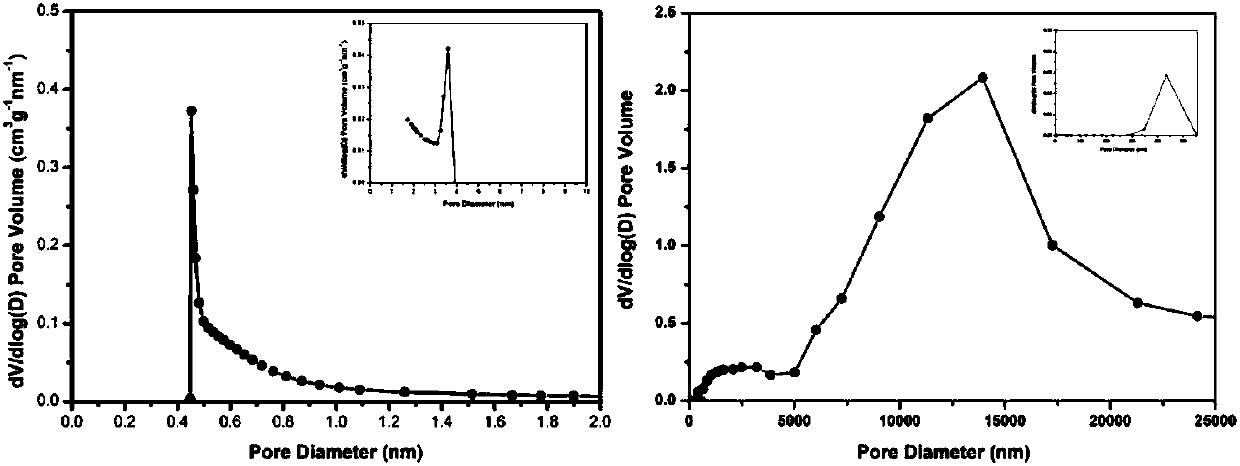

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com