Multi-response carbon quantum dot as well as preparation method and application thereof

A carbon quantum dot, multiple response technology, applied in chemical instruments and methods, fluorescence/phosphorescence, luminescent materials, etc., can solve the problem of rare multiple response carbon dots, and achieve excellent environmental response performance, simple synthesis process, and post-processing steps. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing multiple response carbon quantum dots, specifically:

[0030] (1) Add citric acid and ethylenediamine into deionized water at a molar ratio of 2:3, stir, and after the citric acid is fully dissolved, move it into a microwave reaction tank and react at 190°C for 25 minutes. After the reaction, the molecular weight cut-off is 500 The dialysis membrane is dialyzed and dried in a freeze-drying box for 72 hours to obtain citric acid carbon dots;

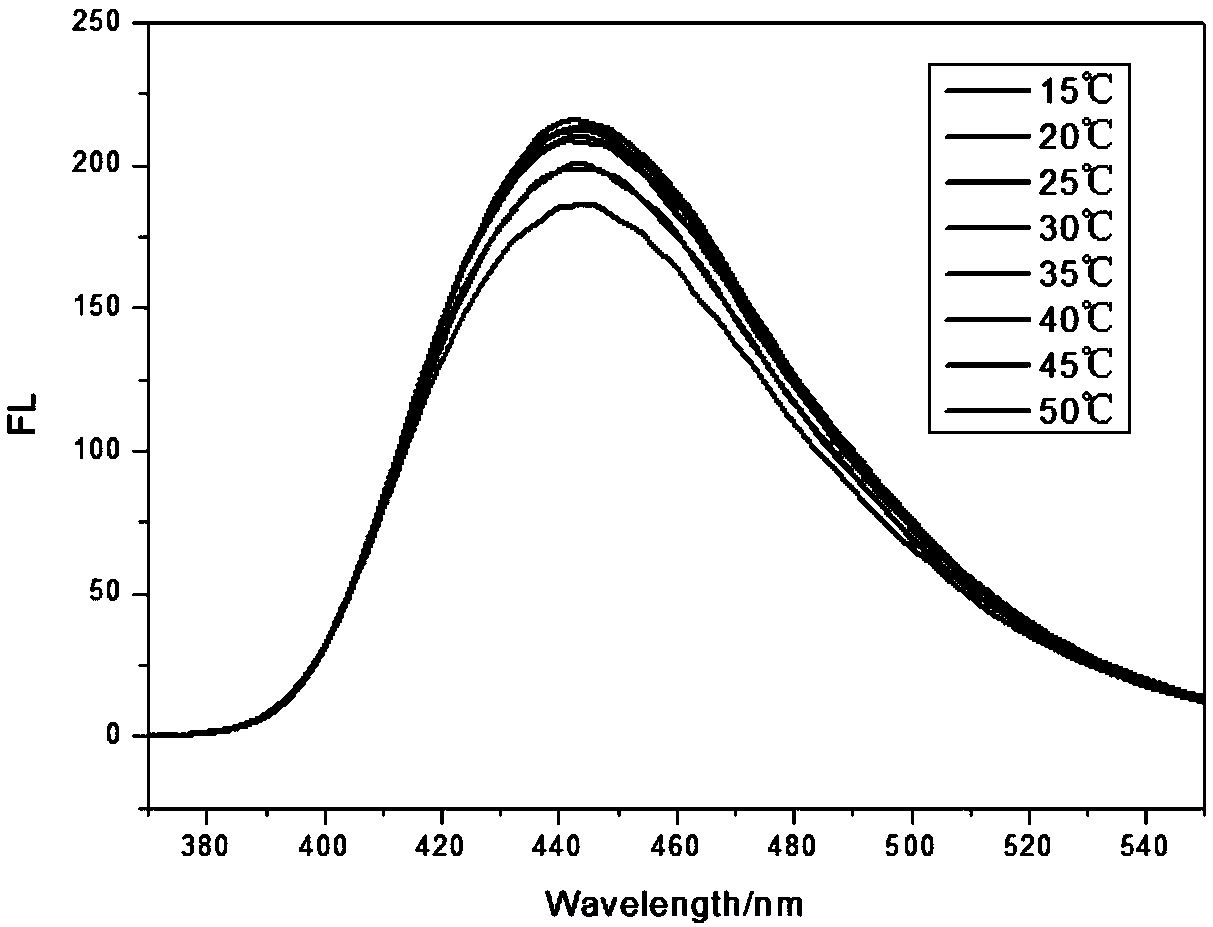

[0031] The citric acid carbon dots are brownish-red powders, which are stable when dissolved in an aqueous solution, and there is no precipitation after standing for a month; the citric acid carbon dots have a strong fluorescence effect, and the quantum efficiency is 78%; and the particle size distribution is uniform, Such as figure 1 As shown, it is about 5nm;

[0032] (2) Dissolve the carbon point of citric acid obtained in step (1) in deionized water, add 8 times the mass of glyc...

Embodiment 2

[0038] Compared with Example 1, the difference is only that the steps (2), (3) are specifically:

[0039] (2) Dissolve the carbon point of citric acid obtained in step (1) in deionized water, add 6 times the mass of glycidyl methacrylate after fully dissolving, and stir at 25°C for 36h. After the reaction is over, let the product stand, After the product was separated, the lower aqueous phase was removed and dried for 72 hours to obtain the GMA-CQD radical;

[0040](3) Dissolve the GMA-CQD free radical obtained in step (2) with N,N-diethylacrylamide and acrylic acid in ethanol at a mass ratio of 1:28:3, then add 10wt‰AIBN, under nitrogen atmosphere, After reacting at 60°C for 10 hours, the product was precipitated in a tetrahydrofuran / petroleum ether system, that is, multiple response carbon quantum dots.

Embodiment 3

[0042] Compared with Example 1, the difference is only that the steps (2), (3) are specifically:

[0043] (2) Dissolve the carbon point of citric acid obtained in step (1) in deionized water, add glycidyl methacrylate 10 times its mass after fully dissolving, stir at 32°C for 12 hours, and after the reaction is over, let the product stand, After the product was separated, the lower aqueous phase was removed and dried for 72 hours to obtain the GMA-CQD radical;

[0044] (3) Dissolve the GMA-CQD free radical obtained in step (2) with N,N-diethylacrylamide and acrylic acid in ethanol at a mass ratio of 5:32:7, then add 10wt‰AIBN, under nitrogen atmosphere, After reacting at 75°C for 5 hours, the product was precipitated in a tetrahydrofuran / petroleum ether system, that is, multiple response carbon quantum dots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com