Heavy-duty waterproof coating, preparation method thereof, special building, ship and car

A waterproof coating and heavy-duty anti-corrosion technology, applied in the direction of anti-corrosion coatings, etc., can solve the problems of poor adhesion, poor water resistance, and inability to meet the needs of industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

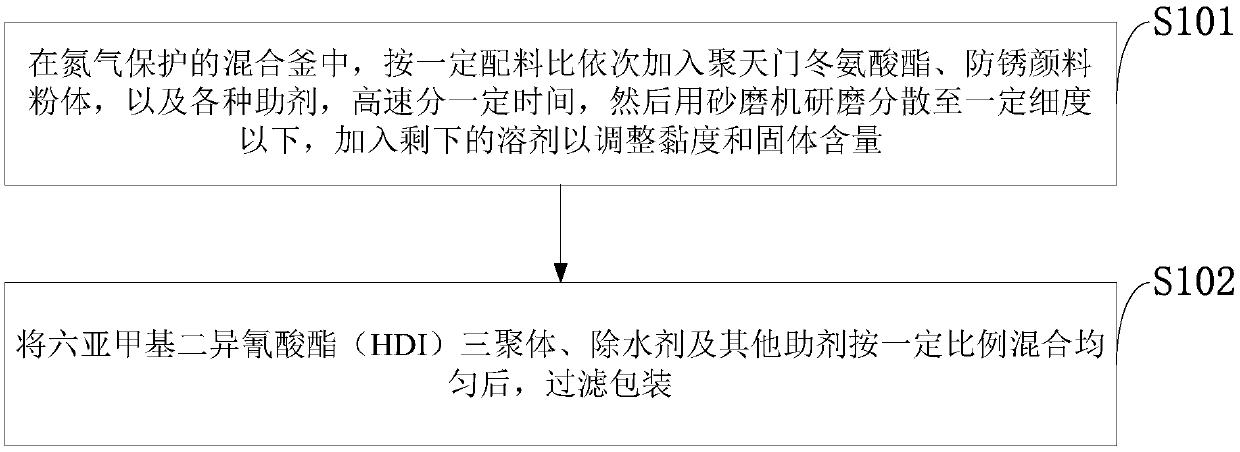

[0018] Such as figure 1 As shown, the preparation method of the heavy-duty anti-corrosion waterproof coating that the embodiment of the present invention provides comprises the following steps:

[0019] S101: Add polyaspartic acid ester, anti-rust pigment powder, and various additives in sequence according to a certain proportion in a nitrogen-protected mixing kettle, divide at high speed for a certain period of time, and then grind and disperse to a certain fineness with a sand mill. Below the temperature, add the remaining solvent to adjust the viscosity and solid content;

[0020] S102: After uniformly mixing hexamethylene diisocyanate (HDI) trimer, water remover and other additives in a certain proportion, filter and pack.

Embodiment 3

[0025]The present invention aims at the technical problem that the existing polyaspartic acid ester as a film former cannot produce high-performance heavy-duty anti-corrosion and waterproof coatings, adopts the polyaspartic acid ester resin with a new structure in the early stage to form a film former compound system, and prepares High-performance polyaspartic resin heavy-duty waterproof coating. Nano titanium dioxide is molecularly modified with titanate coupling agent to reduce the surface Gibbs energy of titanium dioxide, and at the same time, the steric hindrance of organic groups is used to prevent the titanium dioxide particles from approaching each other and prevent the agglomeration of titanium dioxide; then the molecularly modified titanium dioxide The powder is mixed with the magnet powder to prepare composite iron-titanium powder with high dispersion. Doped with an anti-corrosion functional material - polyaniline, to improve the anti-corrosion performance of polyasp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com