Preparation method of indium zinc sulfide and titanium dioxide heterojunction nano material

A titanium dioxide and nanomaterial technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of instability, low utilization rate of sunlight and photon quantum efficiency, high activity, and achieve large specific surface area, which is conducive to efficient collection and separation , the effect of high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a heterojunction nanomaterial 1 of sulfur indium zinc and titanium dioxide, comprising the following steps:

[0033]1) Weigh 5mL tetrabutyl titanate, 10mL absolute ethanol and 3mL acetic acid, then place tetrabutyl titanate, absolute ethanol and acetic acid in a glass container, seal the container mouth, and continuously stir the solution with a magnetic stirrer 2h, to obtain a uniform mixed solution;

[0034] 2) Add 1 mL of vinylpyrrolidone to the mixed solution, seal and stir to obtain an electrospinning precursor;

[0035] 3) Place the electrospinning precursor in the syringe of the electrospinning machine, and carry out electrospinning under the conditions of a voltage of 15kV and a feeding rate of 1.5mL / h, and transfer the electrospinning precursor from the syringe of the electrospinning machine Feed it into the collection device (the collection device is a stainless steel plate covered with aluminum foil) 20cm away from the syringe of the ...

Embodiment 2

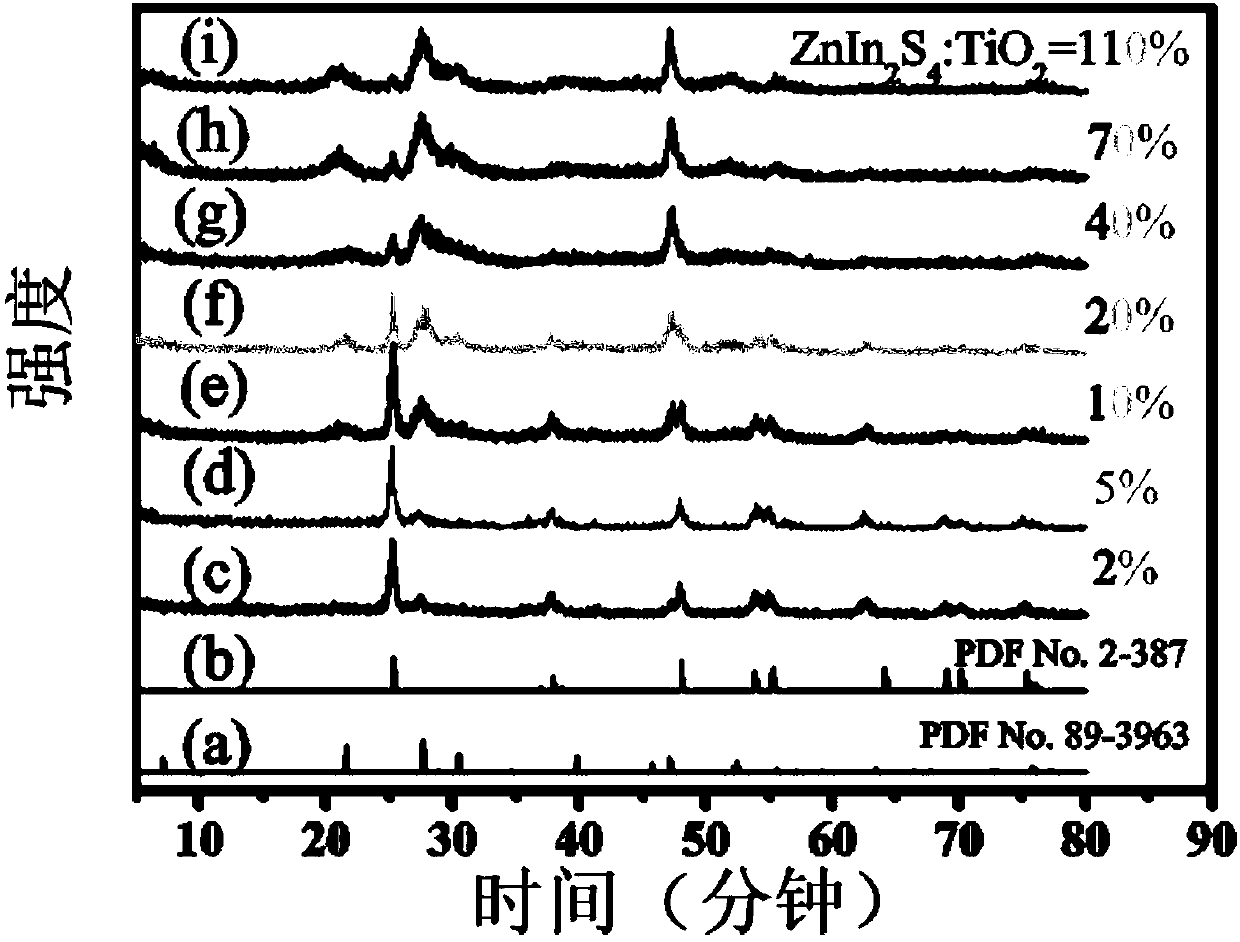

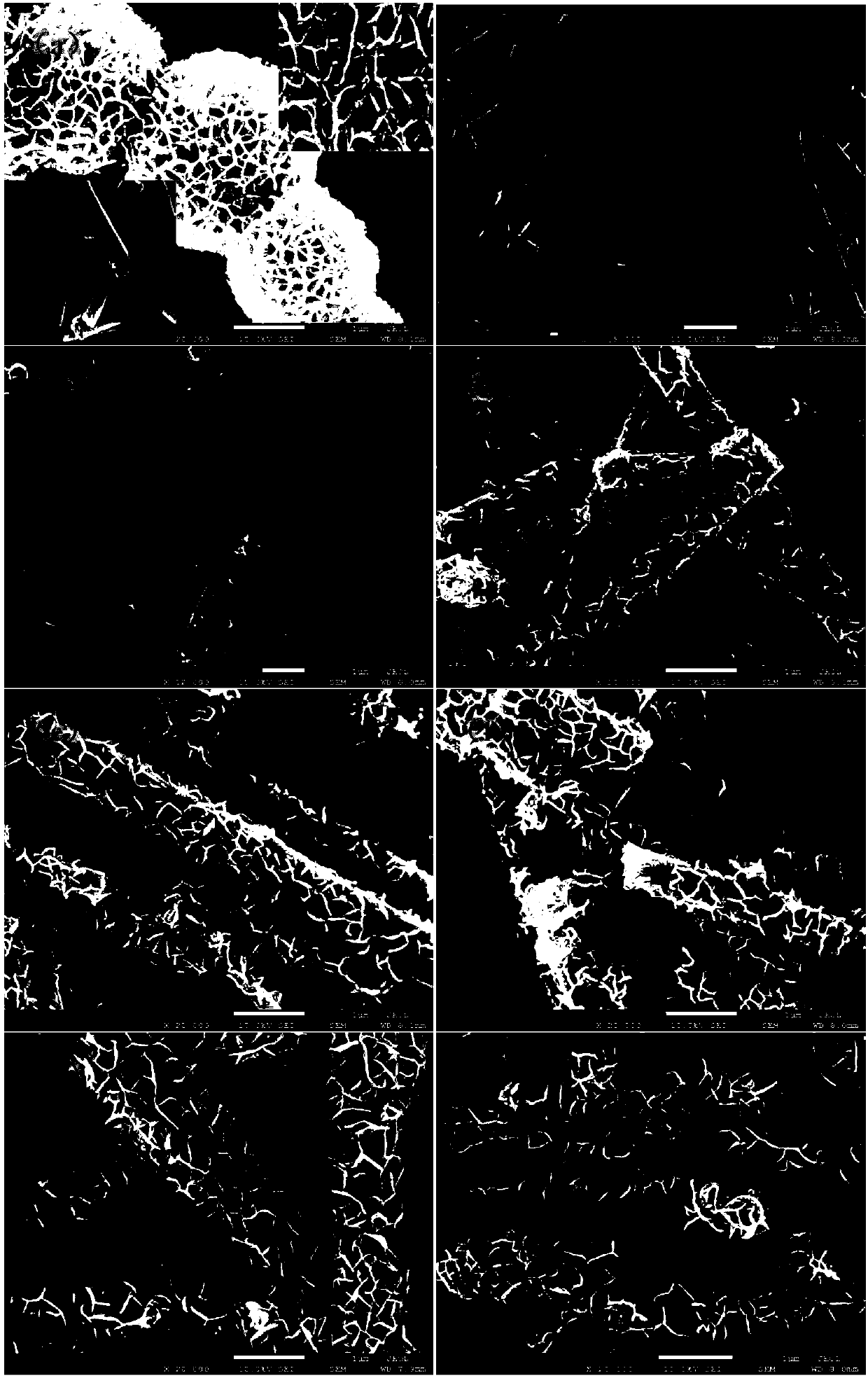

[0041] Keep steps 1-3 in Example 1 unchanged, and do not carry out steps 4-5 in Example 1, directly the TiO obtained by electrospinning 2 Nanorods were characterized and tested for photocatalysis. Get TiO 2 XRD of nanorods and figure 1 The standard spectrum of bPDF No.2-387 is consistent, and the SEM image of the micro-morphology is figure 2 As shown in a, the photocatalytic effect is Figure 4 TiO 2 The nanofibers are shown in polylines.

Embodiment 3

[0043] This embodiment prepares ZnIn 2 S 4 / TiO 2 The method of the heterojunction nanocomposite material 2 is basically the same as the steps of Example 1, except that:

[0044] TiO in step 5 2 The amount of nanorods is 1.8g, thus the ZnIn 2 S 4 / TiO 2 Heterojunction Nanocomposite 2, ZnIn 2 S 4 / TiO 2 ZnIn in heterojunction nanocomposites 2 2 S 4 with TiO 2 The molar ratio is 2:100.

[0045] Its ZnIn 2 S 4 / TiO 2 The SEM of the microstructure of the heterojunction nanocomposite 2 is shown in Figure 2b, and the photocatalytic effect is Figure 4 The polyline inside ZIS2 is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com