Pb-contaminated soil stabilizer and preparation method thereof

A technology of lead-contaminated soil and curing agent is applied in the field of soil remediation to achieve the effects of reducing the dissolution of lead, reducing migration and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The lead-contaminated soil solidifying agent of the present embodiment is made of the following raw materials: 30kg of red mud, 20kg of carbide slag, 20kg of fly ash, 10kg of sodium dihydrogen phosphate, 15kg of diatomite, 10kg of superphosphate and fatty alcohol Oxyethylene ether sodium sulfate 15kg.

[0021] The preparation method of the above-mentioned lead-contaminated soil solidifying agent comprises the steps of: taking raw materials of the following weight: 30kg of red mud, 20kg of carbide slag, 20kg of fly ash, 10kg of sodium dihydrogen phosphate, 15kg of diatomaceous earth, 10kg of superphosphate and fat Alcohol polyoxyethylene ether sodium sulfate 15kg, after mixing uniformly, packs, promptly obtains described lead-contaminated soil curing agent.

Embodiment 2

[0023] The solidifying agent for lead-contaminated soil of the present embodiment is made from the following raw materials: 20kg of red mud, 30kg of carbide slag, 15kg of fly ash, 15kg of sodium dihydrogen phosphate, 10kg of diatomite, 15kg of superphosphate and fatty alcohol polymer Oxyethylene ether sodium sulfate 10kg.

[0024] The preparation method of the above-mentioned lead-contaminated soil solidifying agent comprises the steps of: getting raw materials of the following weight: 20kg of red mud, 30kg of carbide slag, 15kg of fly ash, 15kg of sodium dihydrogen phosphate, 10kg of diatomaceous earth, 15kg of superphosphate and fat Alcohol polyoxyethylene ether sodium sulfate 10kg, after mixing uniformly, packs, promptly obtains described lead-contaminated soil curing agent.

Embodiment 3

[0026] The lead-contaminated soil curing agent of the present embodiment is made of the following raw materials: 40kg of red mud, 10kg of carbide slag, 25kg of fly ash, 5kg of sodium dihydrogen phosphate, 20kg of diatomaceous earth, 5kg of superphosphate and fatty alcohol polymer Oxyethylene ether sodium sulfate 20kg.

[0027] The preparation method of the above-mentioned lead-contaminated soil solidifying agent comprises the steps of: getting raw materials of the following weight: 40kg of red mud, 10kg of carbide slag, 25kg of fly ash, 5kg of sodium dihydrogen phosphate, 20kg of diatomaceous earth, 5kg of superphosphate and fat Alcohol polyoxyethylene ether sodium sulfate 20kg, after mixing uniformly, packs, promptly obtains described lead-contaminated soil curing agent.

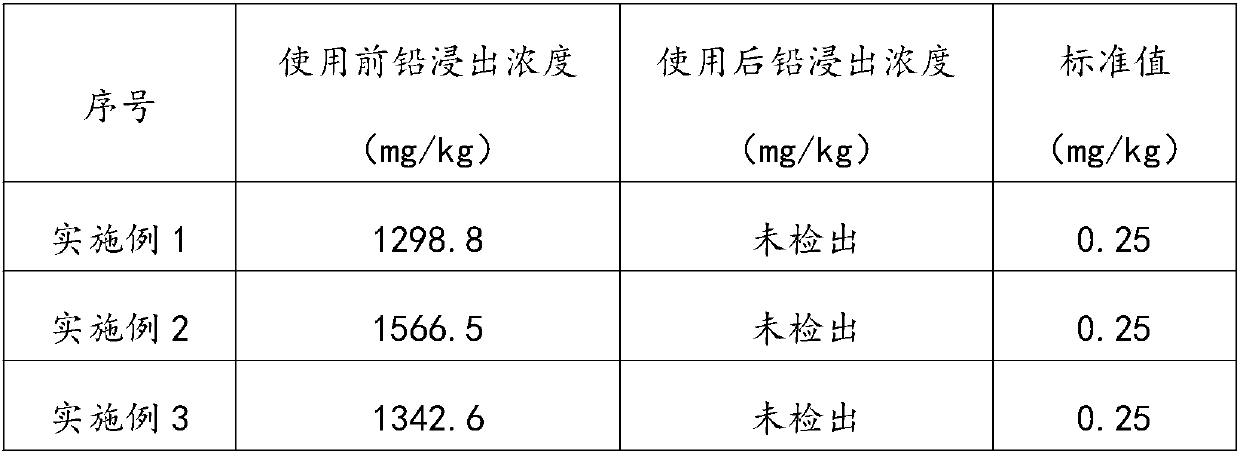

[0028] The lead-contaminated soil curing agent obtained in Examples 1-3 is used in lead-contaminated soil, as shown in Table 1.

[0029] Table 1 The effect of the lead-contaminated soil solidifying agent o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com