Method for fabricating thin film circuits on warped co-fired ceramic substrate

A technology of thin-film circuits and co-fired ceramics, which is used in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the uneven thickness of the dielectric layer and weaken the adhesion at the interface between the co-fired ceramic substrate and the organic dielectric layer of the thin-film circuit. , Substrate scrap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

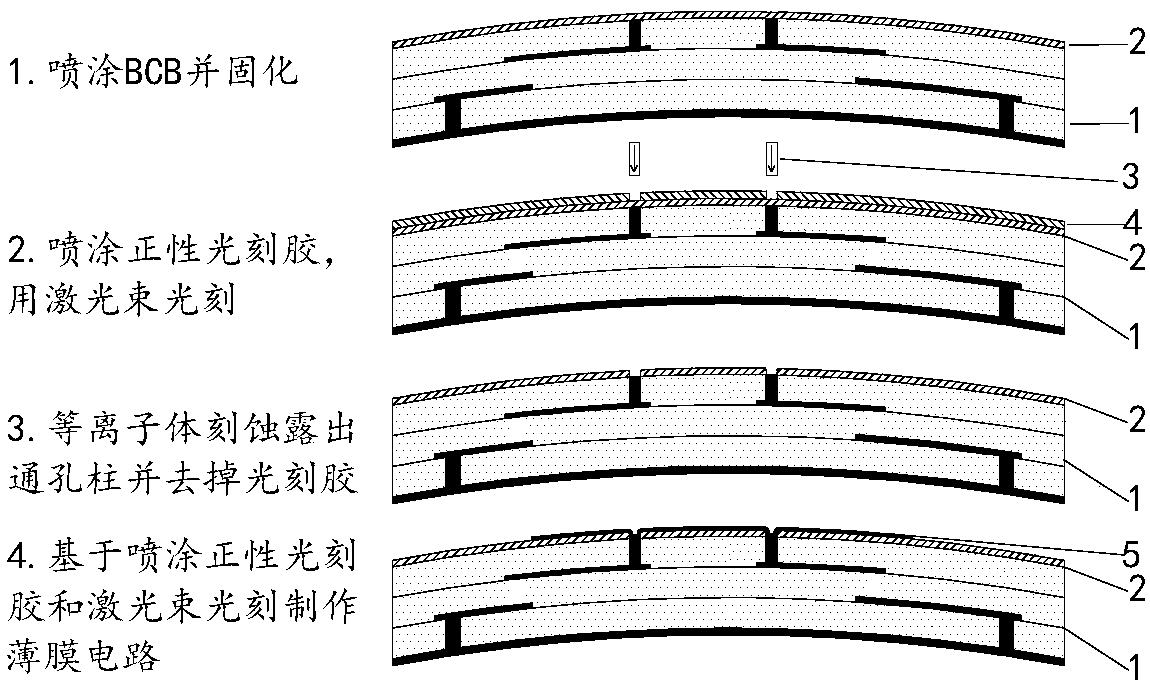

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as figure 2 As shown, a method for manufacturing a thin film circuit on a warped co-fired ceramic substrate comprises the following steps:

[0029] 1) The co-fired ceramic substrate is selected as a 10-layer LTCC instant-fired substrate. After the sintering furnace is taken out, it is stored in a clean box to avoid contamination. The warpage is 30 μm and the surface roughness is 250 nm; bake at 120 ° C for two hours before use. Spray BCB and cure: first spray BCB adhesion enhancer AP3000 with a molecular layer thickness, blow dry with nitrogen, then spray BCB3022-35 glue, and then cure in a nitrogen atmosphere furnace according to the BCB curing temperature curve, and the thickness after curing is 1 μm;

[0030] 2) Spray positive photoresist AZ4620 on the cured BCB dielectric layer, and use the laser beam of 355nm laser drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com