Preparation method of one-dimensional coaxial flexible composite electrode material

A composite electrode and coaxial technology, applied in the field of materials, can solve the problems of structural instability of flexible materials, low loading of electrode active materials, poor electrochemical performance, etc., achieve good mechanical stability, improve electrical conductivity, and have self- supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

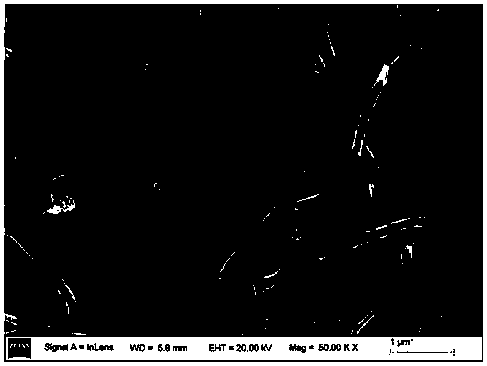

[0027] (1) Weigh 1g of polyacrylonitrile and dissolve it in 8g of N,N-dimethylformamide, stir at room temperature to obtain a uniform and transparent solution;

[0028] (2) Add 0.11g of one-dimensional manganese dioxide nanorods to the transparent solution obtained in step (1), and stir magnetically at 400r / min for 36h to obtain a uniformly dispersed spinning solution; wherein, the used one-dimensional manganese dioxide nanorods Dissolve 0.4g of potassium permanganate and 1g of concentrated hydrochloric acid purchased from Beijing Tongguang Fine Chemical Co., Ltd. in 45ml of deionized water, then transfer the obtained solution to a 50ml polytetrafluoroethylene reactor, and the reactor Put it in an oven at 140° C. for hydrothermal reaction for 5 hours, and cool down to room temperature naturally. The obtained tan powder was washed with deionized water to neutrality and then dried at 80°C to obtain one-dimensional manganese dioxide nanorods.

[0029] (3) the uniformly dispersed...

Embodiment 2

[0032] (1) Weigh 1g of polyacrylonitrile and dissolve it in 10g of N,N-dimethylformamide, stir at room temperature to obtain a uniform and transparent solution;

[0033] (2) Add 0.43g of one-dimensional manganese dioxide nanorods to the transparent solution obtained in step (1), and stir magnetically at 500r / min for 20h to obtain a uniformly dispersed spinning solution; wherein the preparation method and embodiment of one-dimensional manganese dioxide 1 is the same.

[0034] (3) the uniformly dispersed spinning solution that step (2) obtains is 0.8mm in needle inner diameter, and the distance of injection needle and receiving roller is 20cm, and the static voltage applied between receiving roller and needle is 20kV, and injection rate is 0.8ml / h, the temperature is 30 ° C, and the humidity is 25% under the condition of spinning for 6 hours to prepare the coaxial composite fiber precursor;

[0035] (4) The obtained nanofiber precursor was heated in air at a rate of 5° C. / min,...

Embodiment 3

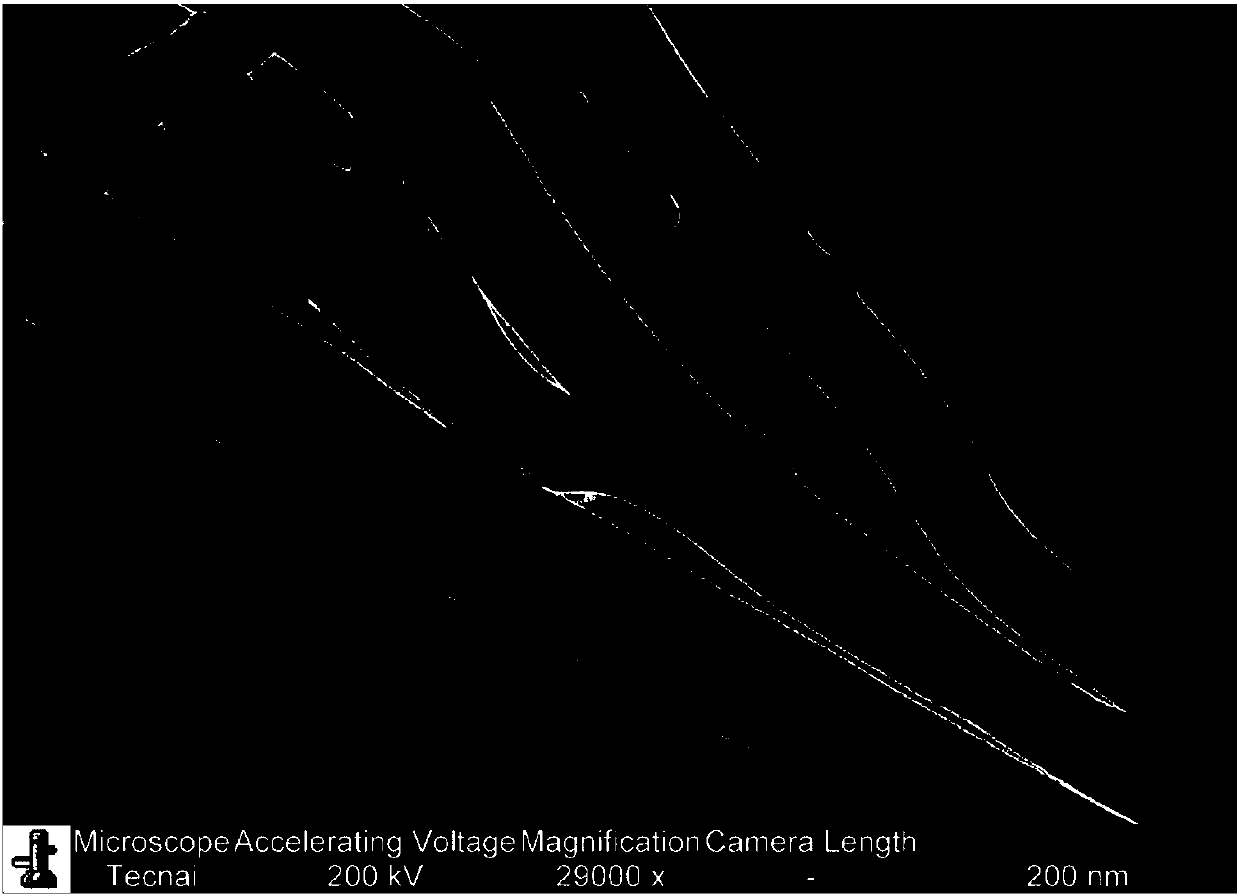

[0037] (1) Weigh 1g of polyacrylonitrile and dissolve it in 12g of N,N-dimethylformamide, stir at room temperature to obtain a uniform and transparent solution;

[0038] (2) 1.5g one-dimensional manganese dioxide nanorods are added to the transparent solution obtained in step (1), and 800r / min magnetic stirring is carried out for 36h to obtain a uniformly dispersed spinning solution; wherein the preparation method of one-dimensional manganese dioxide nanorods is the same as Example 1 is the same.

[0039] (3) the uniformly dispersed spinning solution that step (2) obtains is 0.8mm in needle internal diameter, and the distance of injection needle and receiving roller is 15cm, and the static voltage applied between receiving roller and needle is 25kV, and injection rate is 0.5ml / h, the temperature is 25 ° C, and the humidity is 20% under the condition of spinning for 12 hours to prepare the coaxial composite fiber precursor;

[0040] (4) The obtained nanofiber precursor was he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com