Blood purification adsorbent for uremia and preparation method of adsorbent

A blood purification and adsorbent technology, applied in chemical instruments and methods, blood circulation treatment, suction equipment, etc., can solve the problems of blood compatibility not widely recognized, inability to facilitate blood purification equipment, etc., to improve strength and toughness , the effect of increased strength, increased proportion and uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

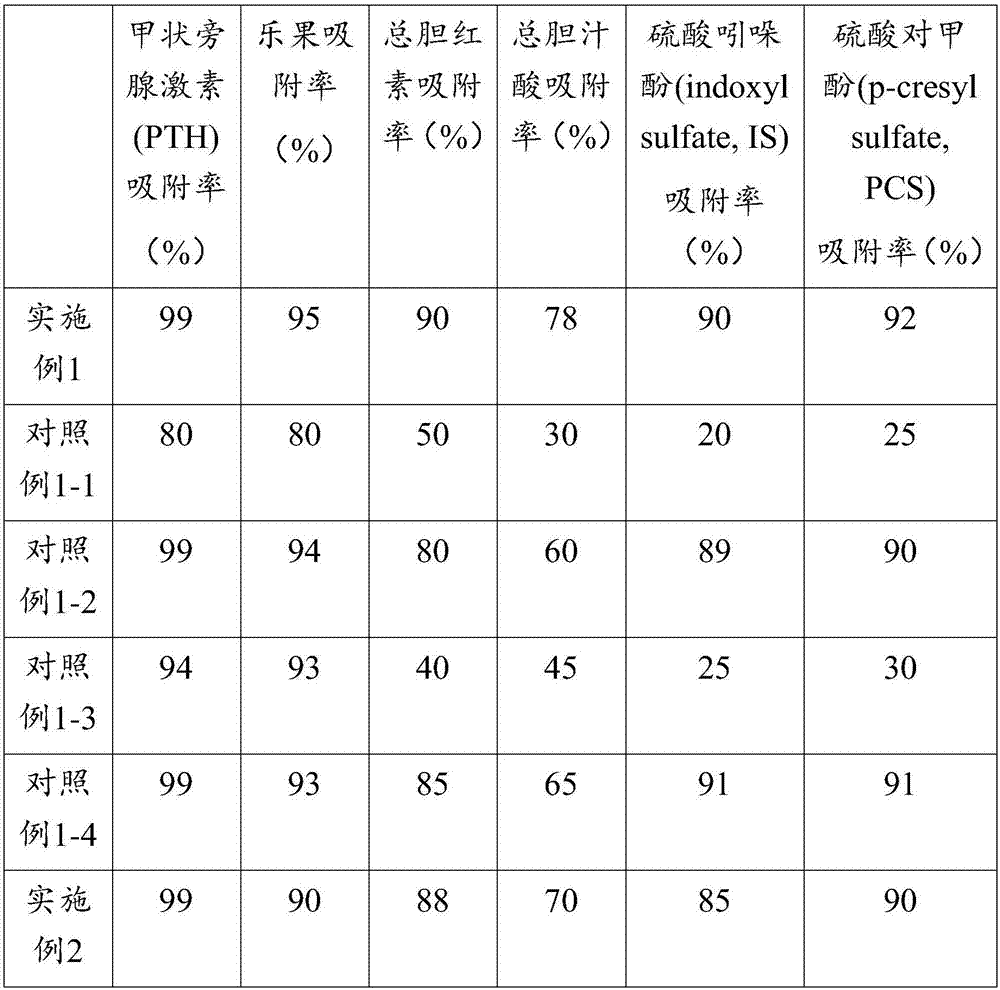

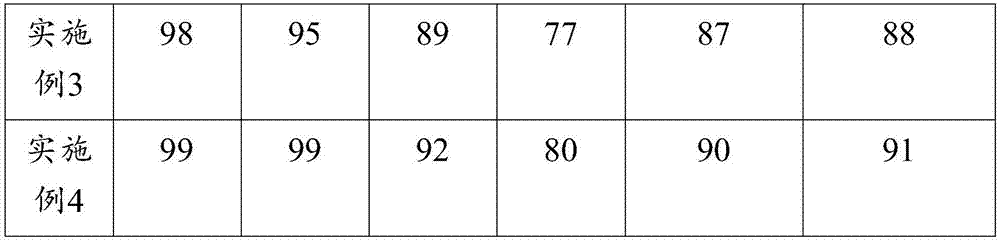

Examples

Embodiment 1

[0038] (1) Suspension polymerization: 80g styrene, 20g divinylbenzene, 3g multi-walled carbon nanotubes, 2g nano-silicon dioxide, 50g toluene, 30g methylcyclohexane, 1.5g benzoyl peroxide, 0.5g Polyethylene glycol (Mn=2000) is stirred evenly to form an oil phase; mix 300g of water and 0.5g of hydroxyethyl cellulose, and stir evenly to obtain a water phase; add the oil phase to the water phase, stir and suspend at 80°C Reacting for 8 hours, removing the porogen in the polymerized resin to obtain polymeric microspheres;

[0039] (2) Chloromethylation reaction: Soak 60g of polymeric microspheres obtained in step (1) in 300g of chloromethyl ether, let stand at 40°C for 8h, add 20g of anhydrous zinc chloride under mechanical stirring, Chloromethylation reaction under conditions for 30 hours to obtain chlorine spheres;

[0040] (3) Post-crosslinking: swell 50 g of chlorine spheres obtained in step (2) in 300 g of nitrobenzene, add 30 g of zinc chloride, and heat and react at 115° C...

Embodiment 2

[0066] (1) Suspension polymerization: 70g styrene, 5g methylstyrene, 25g divinylbenzene, 10g single-walled carbon nanotubes, 5g nano-silicon dioxide, 50g toluene, 30g paraffin, 1.5g benzoyl peroxide, Stir 0.5g of n-butanol evenly to form an oil phase; mix 300g of water and 5g of gelatin, and stir evenly to obtain a water phase; add the oil phase to the water phase, stir and suspend at 60°C for 10 hours, and polymerize the obtained resin The porogen in the process is removed to obtain polymeric microspheres;

[0067] (2) Chloromethylation reaction: Soak 60g of polymeric microspheres obtained in step (1) in 480g of chloromethyl ether, let stand at 90°C for 1h, add 30g of anhydrous zinc chloride under mechanical stirring, and Chloromethylation reaction under conditions for 5 hours to obtain chlorine spheres;

[0068] (3) Post-crosslinking: swell 50 g of chlorine spheres obtained in step (2) in 400 g of ethylene dichloride, add 10 g of ferric chloride, and heat and react at 60° C...

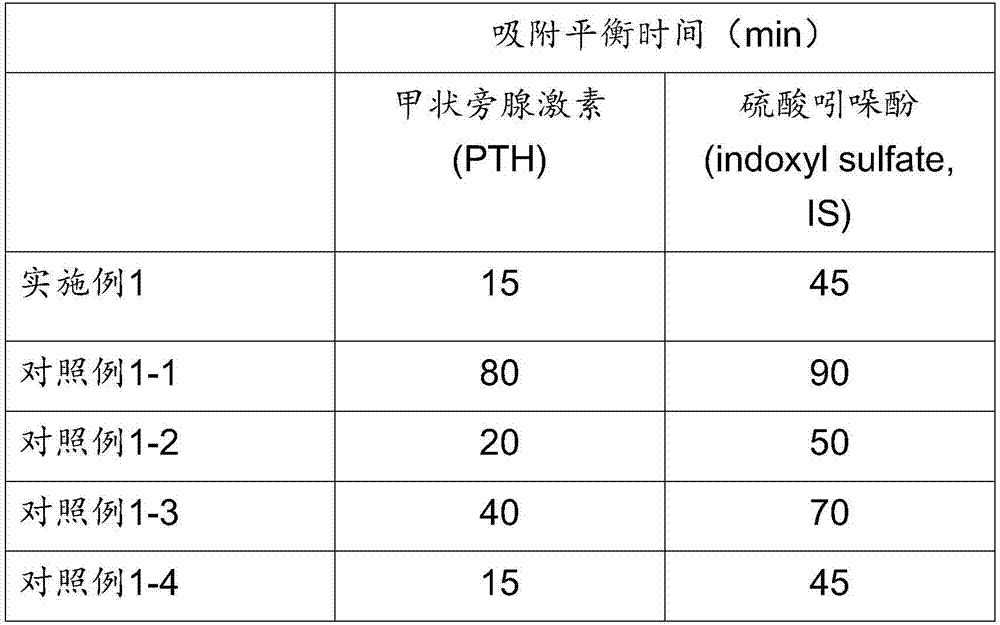

Embodiment 3

[0074](1) Suspension polymerization: 70g styrene, 30g divinylbenzene, 5g multi-walled carbon nanotubes, 5g nano-silicon dioxide, 50g toluene, 30g cyclohexane, 1g azobisisobutyronitrile, 1g isopropanol Stir evenly to form an oil phase; mix 300g water and 0.5g hydroxyethyl cellulose, and stir evenly to obtain a water phase; add the oil phase to the water phase, stir and suspend at 80°C for 8 hours, and polymerize the obtained resin The porogen in the process is removed to obtain polymeric microspheres;

[0075] (2) Chloromethylation reaction: Soak 60g of polymeric microspheres obtained in step (1) in 300g of chloromethyl ether, let stand at 40°C for 20h, add 20g of anhydrous zinc chloride under mechanical stirring, Chloromethylation reaction under conditions for 30 hours to obtain chlorine spheres;

[0076] (3) Post-crosslinking: swell 50 g of chlorine spheres obtained in step (2) in 300 g of nitrobenzene, add 30 g of zinc chloride, and heat and react at 125° C. for 7 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com