Mineral admixture core material for precast concrete

A technology of mineral admixtures and prefabricated components, applied in the field of concrete, can solve the problems of untargeted product and component design, low slump, high early strength and high durability, etc., to improve comprehensive performance and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

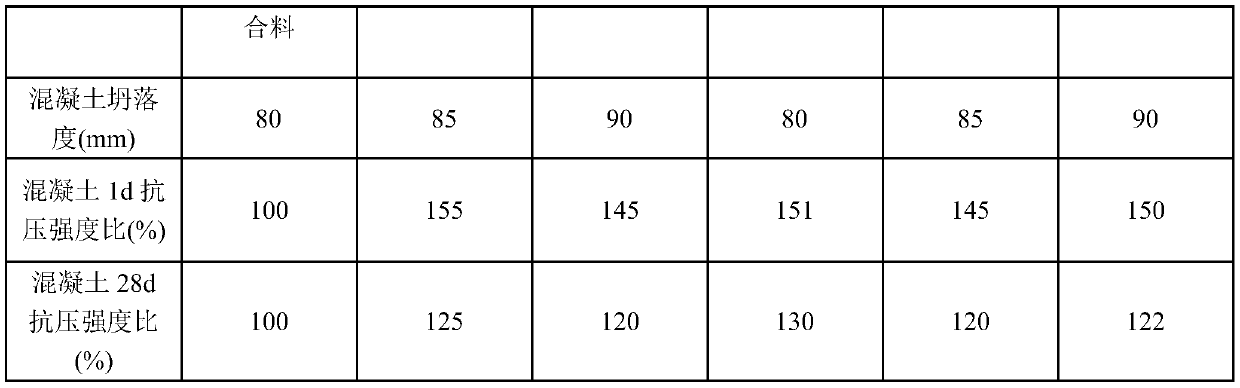

Examples

Embodiment 2

[0040] A kind of mineral admixture core material for prefabricated component concrete, its raw material formula comprises the following components by weight percentage:

[0041]The composition is CaO: 60wt%, Al 2 o 3 : 25wt%, Fe 2 o 3 : 15wt% high-iron calcium aluminate cement: 34.4%;

[0042] Specific surface area 857m 2 / kg ultrafine mineral powder: 18%;

[0044] Coupling agent active coated lightweight hollow microspheres (D(90)=3.5μm, bulk density=476kg / m 3 ): 7.6%;

[0045] Anhydrite whiskers with an average diameter of 3-4 μm and an average length of 50-80 μm: 8.3%;

[0046] Basalt fiber with a single filament diameter of 10-15 μm and an average length of 12-16 μm: 9.0%;

[0047] Melamine superplasticizer powder: 0.7%;

Embodiment 3

[0050] A kind of mineral admixture core material for prefabricated component concrete, its raw material formula comprises the following components by weight percentage:

[0051] The composition is CaO: 62wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 15wt% high iron calcium aluminate cement: 28.9%;

[0052] Specific surface area 912m 2 / kg ultrafine mineral powder: 25%;

[0054] Coupling agent active coated lightweight hollow microspheres (D(90)=4.5μm, bulk density=420kg / m 3 ): 5%;

[0055] Gypsum whiskers: dihydrate gypsum whiskers with an average diameter of 3-4 μm and an average length of 50-80 μm: 10%;

[0056] Inorganic fibers: carbon fibers with a single filament diameter of 10-15 μm and an average length of 12-16 μm: 8.0%;

[0057] Melamine superplasticizer powder: 2.0%;

Embodiment 4

[0060] A kind of mineral admixture core material for prefabricated component concrete, its raw material formula comprises the following components by weight percentage:

[0061] The composition is CaO: 64wt%, Al 2 o 3 : 23wt%, Fe 2 o 3 : 13wt% high-iron calcium aluminate cement: 39.5%;

[0062] Specific surface area 863m 2 / kg ultrafine mineral powder: 19%;

[0063] Magnesium sulfate: 18%;

[0064] Coupling agent active coated lightweight hollow microspheres (D(90) = 2μm, bulk density = 492kg / m 3 ): 8.9%;

[0065] Hemihydrate gypsum whiskers with an average diameter of 3-4 μm and an average length of 50-80 μm: 7.1%;

[0066] Basalt fiber with a single filament diameter of 10-15 μm and an average length of 12-16 μm: 5%;

[0067] Melamine superplasticizer powder: 1.5%;

[0068] Aluminum stearate: 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com