Heat-resistant nitrile hydratase, engineering bacteria and application thereof in production of amide by catalyzing hydration reaction of nitrile compounds

A technology of nitrile hydratase and engineering bacteria, applied in the field of genetic engineering, can solve the problems of poor thermal stability and achieve high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

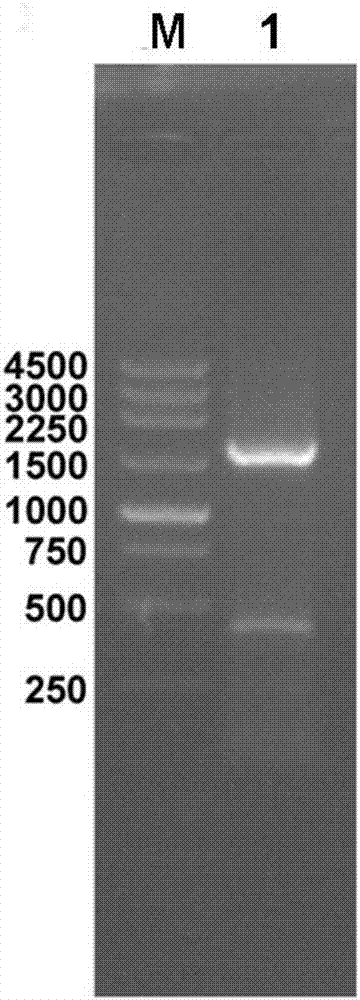

[0042] Cloning of embodiment 1 heat-resistant nitrile hydratase 1229 gene

[0043] The genome of Auromonas manganese oxidans ATCC BAA-1229 was extracted using a bacterial genome extraction kit. Then design primers Ama_Alpha F and Ama_Act R according to the nucleotide sequence (such as SEQ ID NO.7) of putative nitrile hydratase in the genome of Auromonas manganese oxidans ATCC BAA-1229, with Auromonas manganese oxidans ATCC BAA-1229 Using the genome as a template, the full-length nitrile hydratase gene was amplified by PCR. Restriction sites BamHI and HindIII (underlined) were added to the upstream and downstream primers, respectively.

[0044]

[0045] The PCR reaction system and reaction conditions are as follows:

[0046] PCR amplification system:

[0047]

[0048] PCR amplification conditions:

[0049] 1) Pre-denaturation: 95°C for 2 minutes;

[0050] 2) Denaturation: 95°C for 10s; Annealing: 58°C for 15s; Extension: 72°C for 15s; a total of 30 cycles;

[0051] ...

Embodiment 2

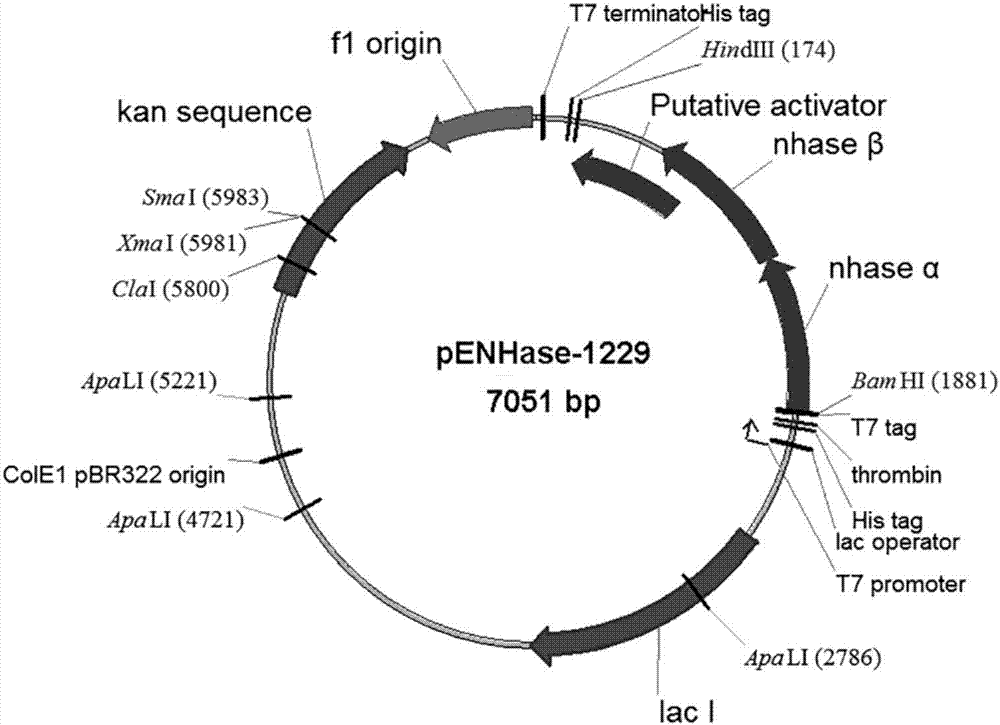

[0055] Embodiment 2 Construction of recombinant heat-resistant nitrile hydratase expression plasmid and genetically engineered bacteria

[0056] In order to realize the high-efficiency functional expression of thermostable nitrile hydratase 1229 gene in Escherichia coli BL21(DE3) cells, the optimized pET28a(+) containing T7 promoter was selected as the expression vector. The vector pET28a(+) and the full-length nitrile hydratase gene were double digested with BamHI and HindIII, and the digested product was recovered using a DNA gel recovery kit.

[0057] Double enzyme digestion system and reaction conditions:

[0061] Add double distilled water to 40 μl;

[0062] Incubate at 37°C for 3h.

[0063] Nucleic acid electrophoresis was used to preliminarily determine the concentration of the two, and the gene / plasmid (mol / mol, 2:1) was mixed, and T4 DNA ligase was added to connect overnight at...

Embodiment 3

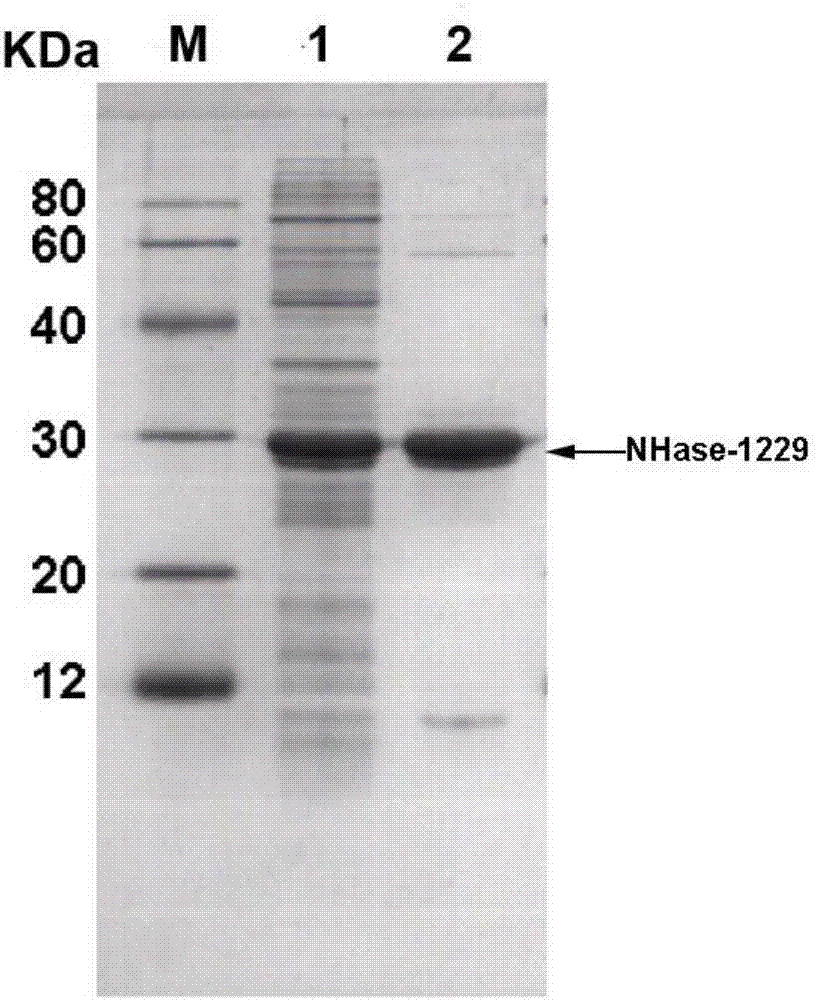

[0064] Example 3 Expression and purification of nitrile hydratase 1229 of genetically engineered E.coli BL21(DE3) / pENHase-1229

[0065] The genetically engineered bacteria E.coli BL21(DE3) / pENHase-1229 glycerol-preserved strain was inoculated in 5 mL of LB liquid medium containing 50 μg / ml Kan, and cultured at 37° C. with shaking at 200 rpm for 10 to 14 hours. Take 2 mL of the culture solution and transfer it to 100 mL of fresh LB liquid medium containing 50 μg / ml Kan, culture at 37°C with shaking at 200 rpm until the cell density (OD600) reaches 0.8, add IPTG to the final concentration of 0.1 mM, 18-37 Induce at ℃ for 12-18 hours. Cells were collected by centrifugation at 5000-10000×g for 5-10 min, washed twice with phosphate buffer (50-200 mM, pH 5.0-8.0), and resuspended in phosphate buffer. In an ice bath, use an ultrasonic breaker to break the cells, centrifuge at 5000-10000×g for 5-30 minutes, collect the supernatant of the broken cells, and pass the supernatant of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com