Epitaxial growth method of high-resistance GaN thin film

A technology of epitaxial growth and thin film, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the decrease of two-dimensional electron gas mobility, affect device performance, and restrict device performance, so as to reduce Ga gap and crystal The effect of high quality and improved surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Choose a slice c Surface sapphire substrate, transfer it to the reaction chamber of MOCVD equipment, in H 2 The temperature was raised to 1100°C under the atmosphere, and the substrate was baked for 5 minutes to clean the surface of the substrate;

[0023] 2) Lower the temperature to 550°C, and feed TMGa and NH into the reaction chamber at the same time 3 ,TMGa / NH 3 The molar ratio (Ⅴ / Ⅲ ratio) is 1500, H 2 As the carrier gas, the pressure of the reaction chamber is 500torr, and the nucleation layer is grown, and the thickness of the nucleation layer is 25nm;

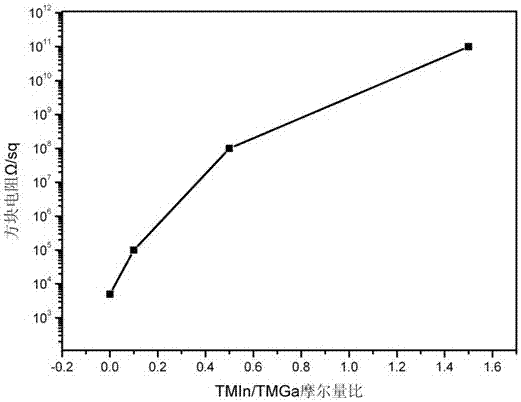

[0024] 3) in NH 3 Under protection, the temperature was increased to 1050 °C, and TMGa and TMIn were introduced into the reaction chamber at the same time to carry out epitaxial growth of high-resistance GaN thin films. The molar ratio of TMIn / TMGa was 0.5, the V / III ratio was 1000, and the H 2 It is the carrier gas, the reaction chamber pressure is 300torr, and the film thickness is 2μm;

[0025] 4) Cool...

Embodiment 2

[0027] 1) Select a Si-faced 4H-SiC substrate, transfer it to the reaction chamber of the MOCVD equipment, and 2 Raise the temperature to 1200°C under the atmosphere, bake the substrate for 5 minutes, and clean the surface of the substrate;

[0028] 2) Lower the temperature to 900°C and feed TMAl and NH into the reaction chamber at the same time 3 , V / III ratio is 1000, H 2 As the carrier gas, the pressure of the reaction chamber is 100torr, and the nucleation layer is grown, and the thickness of the nucleation layer is 60nm;

[0029] 3) in NH 3 Under protection, the temperature was increased to 1100 ° C, and TMGa and TMIn were introduced into the reaction chamber at the same time to carry out epitaxial growth of high-resistance GaN thin films. The molar ratio of TMIn / TMGa was 1.5, and the V / III ratio was 2500. N 2 It is the carrier gas, the reaction chamber pressure is 300torr, and the film thickness is 2μm;

[0030] 4) Cool down to room temperature, and transfer the GaN t...

Embodiment 3

[0032] 1) Select a (111) Si substrate, transfer it to the reaction chamber of the MOCVD equipment, in the H 2 The temperature was raised to 1050°C under the atmosphere, and the substrate was baked for 5 minutes to clean the surface of the substrate;

[0033] 2) Lower the temperature to 850°C, and feed TMAl and NH into the reaction chamber at the same time 3 , V / III ratio is 1000, H 2 As the carrier gas, the pressure of the reaction chamber is 100torr, and the nucleation layer is grown, and the thickness of the nucleation layer is 30nm;

[0034]3) in NH 3 Under protection, raise the temperature to 1020°C, and at the same time feed TMGa and TMIn into the reaction chamber to carry out epitaxial growth of high-resistance GaN thin films. 2 The mixed gas is the carrier gas, the reaction chamber pressure is 100torr, and the film thickness is 4μm;

[0035] 4) Cool down to room temperature, and transfer the GaN thin film material out of the MOCVD equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com