A kind of hollow iron oxide material and preparation method thereof

An iron oxide, hollow technology, applied in iron oxide, chemical instruments and methods, iron oxide/iron hydroxide, etc., can solve the problems of template agent consumption, ammonia water pollution, high temperature energy consumption, etc., to achieve a short process and reduce consumption. Energy and high temperature equipment consumption, the effect of reducing consumption consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

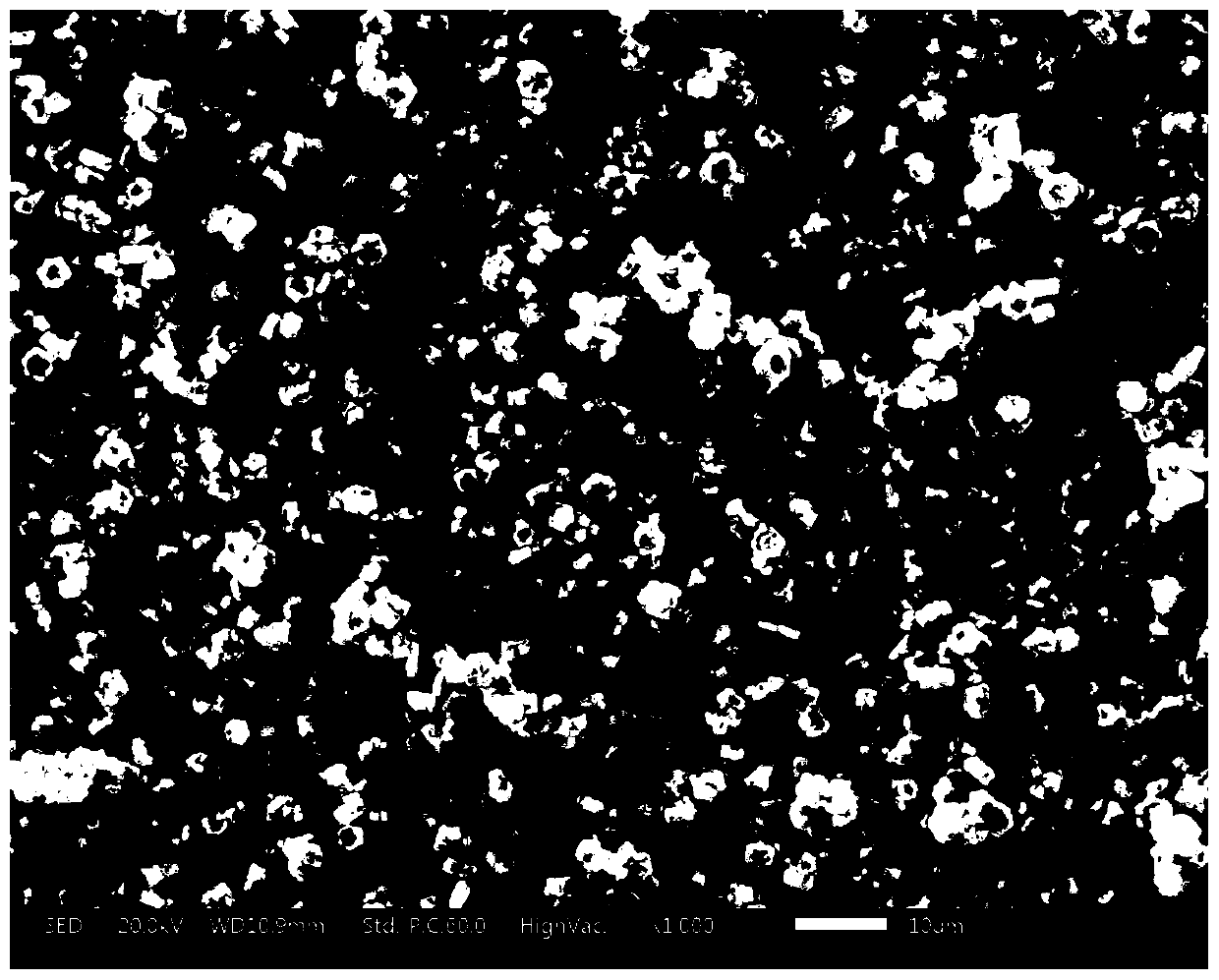

Embodiment 1

[0029] Weigh 2.433g of ferric chloride and dissolve it in 20ml of ultrapure water, add 20ml of N,N-2-methylformamide containing 1.261g of trimesic acid at the same time, then ultrasonically mix for 30min, then add 0.375-1.0ml mass fraction 68% nitric acid, then add 0.8ml of hydrofluoric acid with a mass fraction of 40% as a corrosive agent, then put it into a 60ml reactor, react at 220°C for 2 days, open the reactor to circulate alcohol and ultrapure water to the product After three washes, a red reaction product was obtained.

Embodiment 2

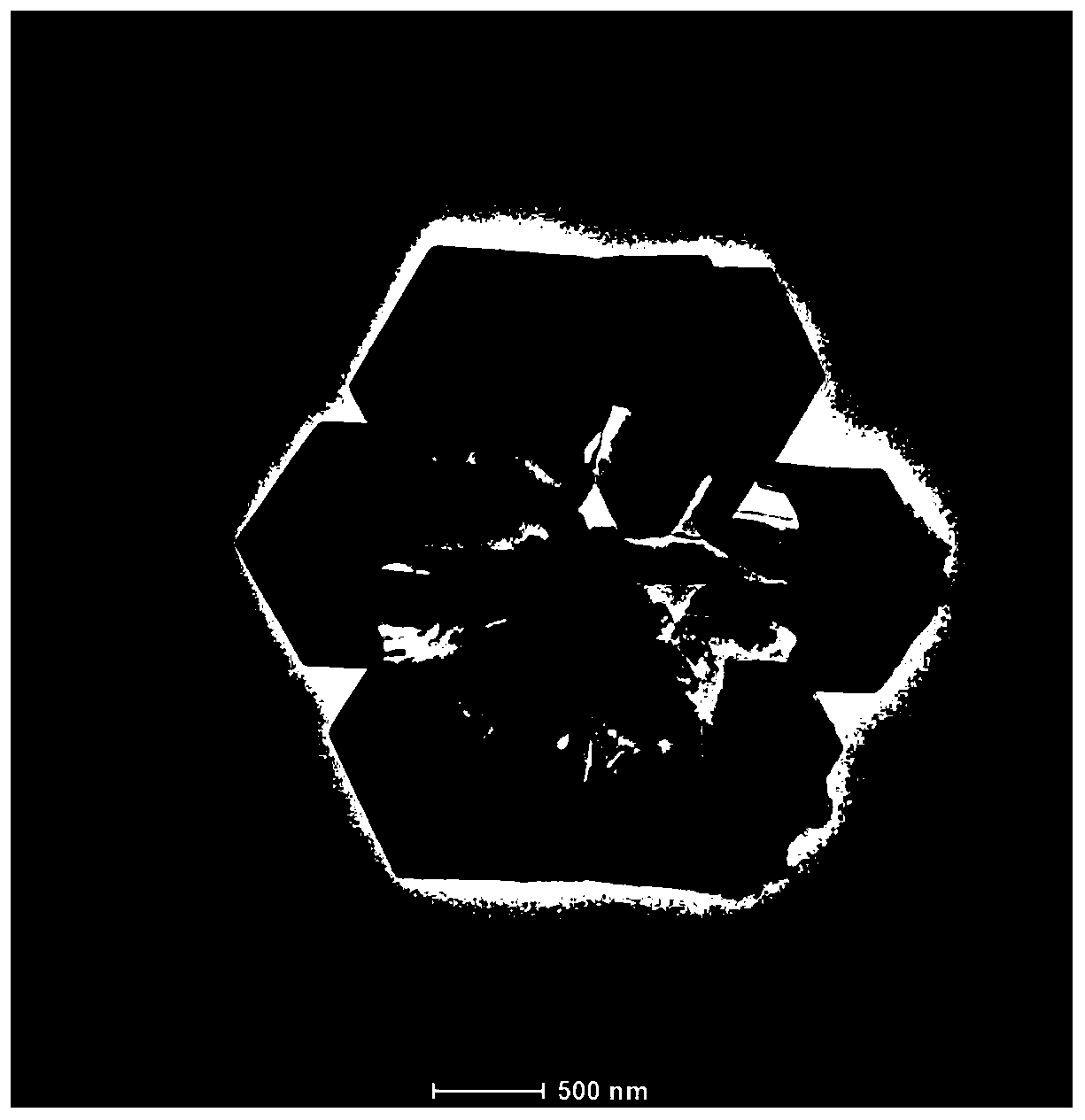

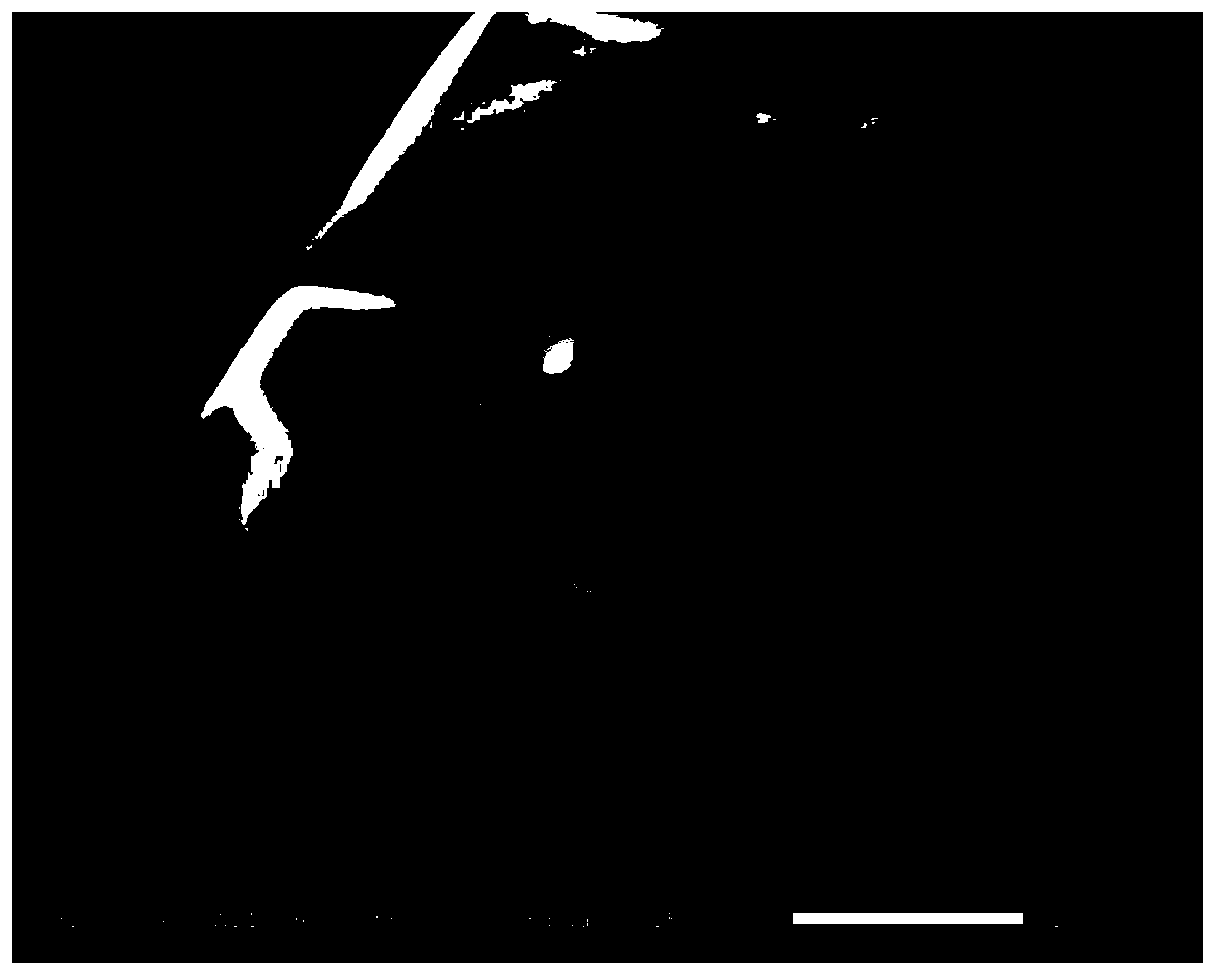

[0031] According to the method of embodiment 1, change wherein the hydrofluoric acid consumption of massfraction 40% that adds reduces to 0.375ml, can obtain as image 3 It can be seen that the etching degree is lower than that of the flower-shaped iron oxide in Example 1 for the flower-shaped iron oxide with moderate and slight central etching. According to Example 1, change and add 1ml of hydrofluoric acid with a mass fraction of 40%, and find that the reaction kettle cannot be opened. After sending it back to the factory to open the kettle, it can be seen that the lining has been damaged as Figure 4 As shown, the inner lining phenomenon of burning still occurred in many experiments. In order to avoid this situation, when the concentration of hydrofluoric acid is too high, the lining of the reaction kettle is made of acid and alkali resistant reinforced polymer imported from the United States. Teflon material, not ordinary PTFE material.

Embodiment 3

[0033] According to the method for embodiment 1, change the time of adding reaction wherein to be 24h, can obtain as Figure 5 Moderately lightly etched flower-like iron oxide material. Change the time of adding the reaction to 48h, you can get as Figure 5 Moderately etched microhollow iron oxide material. Change the time of the added reaction to 72h, you can get as Figure 5 Clearly etched hollow iron oxide material in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com