Corundum firebrick with low heat conductivity and high corrosion resistance, and preparation method thereof

A corundum-based, low-thermal-conduction technology, which is applied in the field of low-thermal-conduction, high-corrosion-resistant corundum refractory bricks and its preparation, can solve the problems of increased mechanical stress on the kiln lining, large thermal load on the kiln body, and large thermal conductivity to reduce pores High efficiency, high temperature performance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The content of each component is represented by mass percent:

[0036] 85% calcium hexaaluminate with particle size ≤5mm,

[0037] α-alumina micropowder 13%,

[0038] Rare metal oxide powder 2%,

[0039] Among them, the rare metal oxide fine powder is mixed with yttrium oxide fine powder and zinc oxide fine powder at a mass ratio of 10:1.

[0040] Its preparation method is as follows:

[0041] The above raw materials are weighed and mixed, based on the mixed powder, add 2% Nai system binder, and mix uniformly to make a mixed powder. Put the above mixed material into a mold, press it with a press, and heat it at 110 ° C. After 24 hours of heat preservation and drying, it is fired in a tunnel kiln at 1550±25°C for 8 hours to make corundum refractory bricks with low thermal conductivity and high corrosion resistance.

[0042] The naphthalene binder is naphthalene sulfonate formaldehyde condensate.

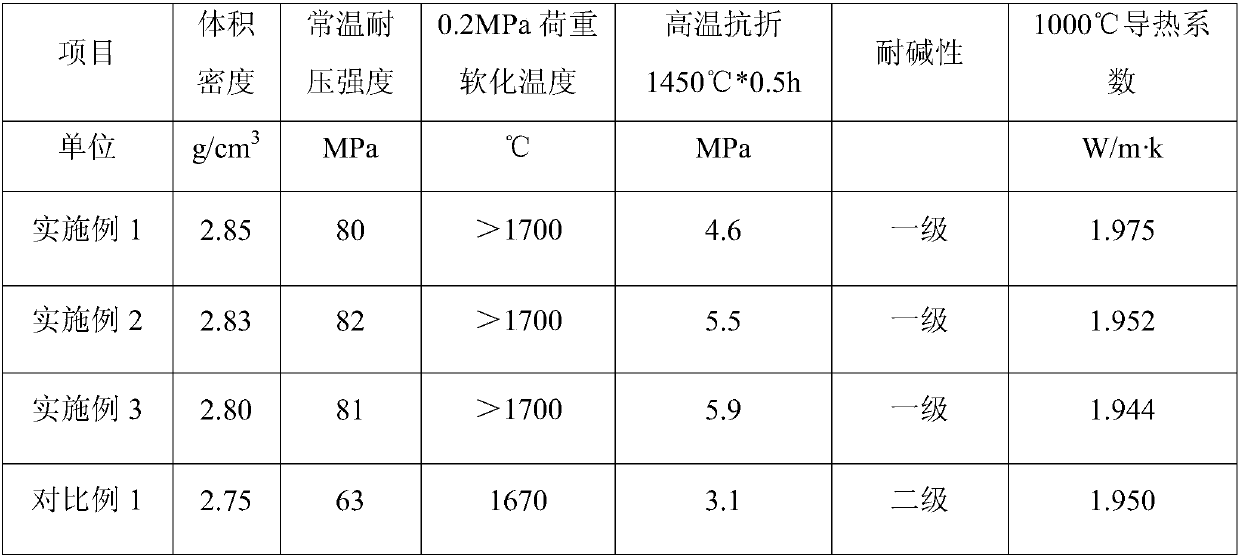

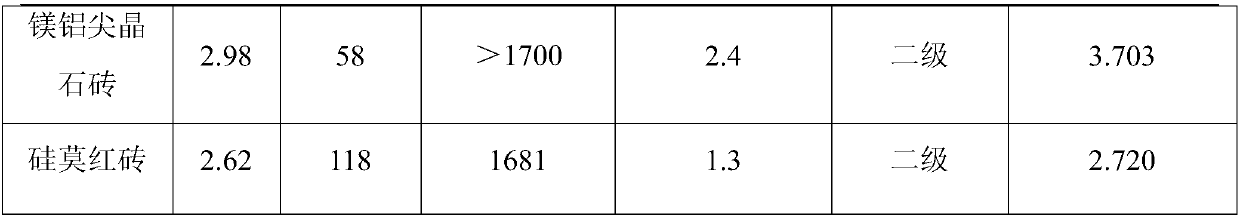

[0043] The performance test results are shown in Table 1.

Embodiment 2

[0045] The content of each component is represented by mass percent:

[0046] 90% calcium hexaaluminate with particle size ≤5mm,

[0047] α-alumina micropowder 8%,

[0048] Rare metal oxide powder 2%,

[0049] Among them, the rare metal oxide powder is mixed with yttrium oxide powder and zinc oxide powder in a mass ratio of 5:5.

[0050] Its preparation method is as follows:

[0051] The above raw materials are weighed and mixed, based on the mixed powder, plus 2% Nai series binder, mixed uniformly to make a mixed powder, the above mixed material is put into a mold, pressed with a press, and heated at 130 ° C. After 24 hours of heat preservation and drying, it is fired in a tunnel kiln at 1600±25°C for 8 hours to make corundum refractory bricks with low thermal conductivity and high corrosion resistance.

[0052] The naphthalene binder is naphthalene sulfonate formaldehyde condensate.

[0053] The performance test results are shown in Table 1.

Embodiment 3

[0055] The content of each component is represented by mass percent:

[0056] Calcium hexaaluminate 92% with particle size ≤5mm,

[0057] α-alumina micropowder 5%,

[0058] Rare metal oxide powder 3%,

[0059] Among them, the rare metal oxide powder is mixed with yttrium oxide powder and zinc oxide powder at a mass ratio of 1:10.

[0060] Its preparation method is as follows:

[0061] Based on the above mixed powder, add 2% of the Na-based binder, mix evenly to make a mixed powder, press the above mixed material with a press, dry it at 130°C for 24 hours, and then keep it in a tunnel kiln at 1675±25°C Fired for 8 hours to make corundum refractory bricks with low thermal conductivity and high corrosion resistance.

[0062] The naphthalene binder is naphthalene sulfonate formaldehyde condensate.

[0063] The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com