Glutaraldehyde preparation method

A technology for glutaraldehyde and acrolein, which is applied in the field of preparing glutaraldehyde by hydrolysis of 2-methoxy-3.4-dihydropyran under negative pressure, can solve the problem that glutaraldehyde solution is easy to change color, cannot be continuously produced, and equipment is anti-corrosion. High requirements for problems, to achieve the effects of high product quality stability, short reaction time, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

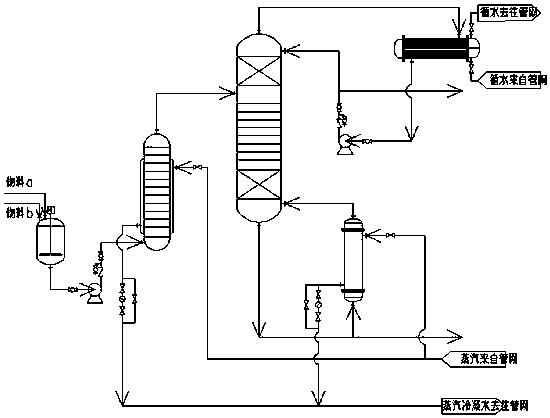

Image

Examples

Embodiment 1

[0024] A method for preparing glutaraldehyde, which uses acetylene, methanol, and acrolein as raw materials to prepare 2-methoxy-3.4-dihydropyran, and then hydrolyzes 2-methoxy-3.4-dihydropyran under negative pressure to prepare Glutaraldehyde, described preparation method comprises the following steps:

[0025] a. Synthesis of vinyl methyl ether: In a pressure vessel, under the conditions of 135°C and an absolute pressure of 0.5Mpa, methanol and acetylene are catalyzed by alkali metal salts of methanol to generate vinyl methyl ether;

[0026] b. Synthesis of pyran: In a reaction vessel, under the conditions of 130°C and an absolute pressure of 3.5Mpa, react acrolein with vinyl methyl ether for 2 hours to generate 2-methoxy-3.4-dihydropyran;

[0027] c. Purification of glutaraldehyde by hydrolysis of pyran: In a tubular reactor, under the condition of 70°C, 2-methoxy-3.4-dihydropyran is mixed with deionized water and then added with a polymerization inhibitor. Under the actio...

Embodiment 2

[0038] A method for preparing glutaraldehyde, which uses acetylene, methanol, and acrolein as raw materials to prepare 2-methoxy-3.4-dihydropyran, and then hydrolyzes 2-methoxy-3.4-dihydropyran under negative pressure to prepare Glutaraldehyde, described preparation method comprises the following steps:

[0039] a. Synthesis of vinyl methyl ether: In a pressure vessel, under the conditions of 140°C and an absolute pressure of 0.6Mpa, methanol and acetylene are catalyzed by alkali metal salts of methanol to generate vinyl methyl ether;

[0040] b. Synthesis of pyran: In a reaction vessel, under the conditions of 140°C and an absolute pressure of 4Mpa, acrolein and vinyl methyl ether are reacted to generate 2-methoxy-3.4-dihydropyran;

[0041] c. Purification of glutaraldehyde by hydrolyzing pyran: In a tubular reactor, mix 2-methoxy-3.4-dihydropyran with deionized water at 79°C and add a polymerization inhibitor, under the catalysis of strong acid resin Carry out pre-reaction ...

Embodiment 3

[0053] A method for preparing glutaraldehyde, which uses acetylene, methanol, and acrolein as raw materials to prepare 2-methoxy-3.4-dihydropyran, and then hydrolyzes 2-methoxy-3.4-dihydropyran under negative pressure to prepare Glutaraldehyde, described preparation method comprises the following steps:

[0054] a. Synthesis of vinyl methyl ether: In a pressure vessel, under the conditions of 130°C and an absolute pressure of 0.4Mpa, methanol and acetylene are catalyzed by alkali metal salts of methanol to generate vinyl methyl ether;

[0055] b. Synthesis of pyran: In a reaction vessel, under the conditions of 150°C and an absolute pressure of 3Mpa, acrolein and vinyl methyl ether are reacted to generate 2-methoxy-3.4-dihydropyran;

[0056] c. Purification of glutaraldehyde by hydrolyzing pyran: In a tubular reactor, under the conditions of 75°C and an absolute pressure of 0.05Mpa, add a polymerization inhibitor after mixing 2-methoxy-3.4-dihydropyran with deionized water , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com