Preparation method of high-yield allantoin

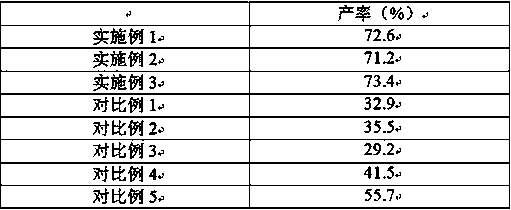

A high-yield technology for allantoin, applied in the field of high-yield allantoin preparation, can solve the problems of low allantoin yield, not very good catalytic effect, equipment corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing allantoin with high yield, comprising:

[0018] 1) Hydrothermal reaction of molecular sieve, tetrabutyl titanate, zirconium source, sodium tungstate, amino acid, ethanol and water to prepare modified molecular sieve;

[0019] 2) Soak the modified molecular sieve in acid solution to obtain active molecular sieve;

[0020] 3) The active molecular sieve, cyclodextrin, nitrate, and water are subjected to a contact reaction and dried to obtain a catalyst for the preparation of allantoin;

[0021] 4) Oxidation reaction of glyoxal and nitric acid to produce glyoxylic acid, and then condensation reaction of glyoxylic acid, urea, and the catalyst to produce allantoin.

[0022] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to make the produced allantoin have a more excellent yield, preferably, in step 1), molecular sieve, titanic acid The weight ratio of tetrabutyl...

Embodiment 1

[0036] 1) Molecular sieve, tetrabutyl titanate, zirconium source (zirconium nitrate), sodium tungstate, amino acid, ethanol, and water are subjected to hydrothermal reaction according to the weight ratio of 10:1.5:0.6:0.4:0.10:7:13 (reaction The temperature is 210°C, and the reaction time is 6h) to prepare modified molecular sieves;

[0037] 2) Soak the modified molecular sieve and acid solution (pH 5.8, hydrochloric acid aqueous solution) according to the weight ratio of 10:40 (soaking temperature is 40°C, soaking time is 20h) to prepare active molecular sieve;

[0038] 3) The active molecular sieve, cyclodextrin, nitrate (sodium nitrate), and water are subjected to a contact reaction according to a weight ratio of 10:0.5:1.3:25 (reaction temperature is 85°C, reaction time is 12h), and dried to obtain Catalyst for the preparation of allantoin;

[0039] 4) Carry out oxidation reaction of glyoxal and nitric acid at a molar ratio of 1:1.1 (reaction temperature is 41°C, reaction...

Embodiment 2

[0041] 1) Molecular sieve, tetrabutyl titanate, zirconium source (zirconium hydroxide), sodium tungstate, amino acid, ethanol, and water are subjected to hydrothermal reaction according to the weight ratio of 10:1:0.5:0.2:0.08:5:10 ( The reaction temperature is 200°C, and the reaction time is 4h) to prepare modified molecular sieves;

[0042] 2) Soak the modified molecular sieve and acid solution (pH 5.5, phosphoric acid aqueous solution) in a weight ratio of 10:30 (soaking temperature is 30°C, soaking time is 12h) to prepare active molecular sieve;

[0043] 3) The active molecular sieve, cyclodextrin, nitrate (potassium nitrate), and water are subjected to a contact reaction in a weight ratio of 10:0.4:1:20 (reaction temperature is 80°C, reaction time is 10h), and dried to obtain Catalyst for the preparation of allantoin;

[0044]4) Carry out oxidation reaction of glyoxal and nitric acid at a molar ratio of 1:1.05 (reaction temperature is 40°C, reaction time is 4h) to produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com