Active ester curing agent and epoxy resin composition

A technology of active ester curing agent and epoxy resin, which is applied in the field of copper clad laminates, can solve the problems of insufficient research on curing agents, and achieve the effects of low hygroscopicity, high reactivity, and low dielectric loss tangent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of above-mentioned active ester curing agent is also provided in the embodiment of the present invention, it comprises:

[0033] S1. Carrying out addition reaction of phenol and dicyclopentadiene to obtain dicyclopentadiene phenol resin;

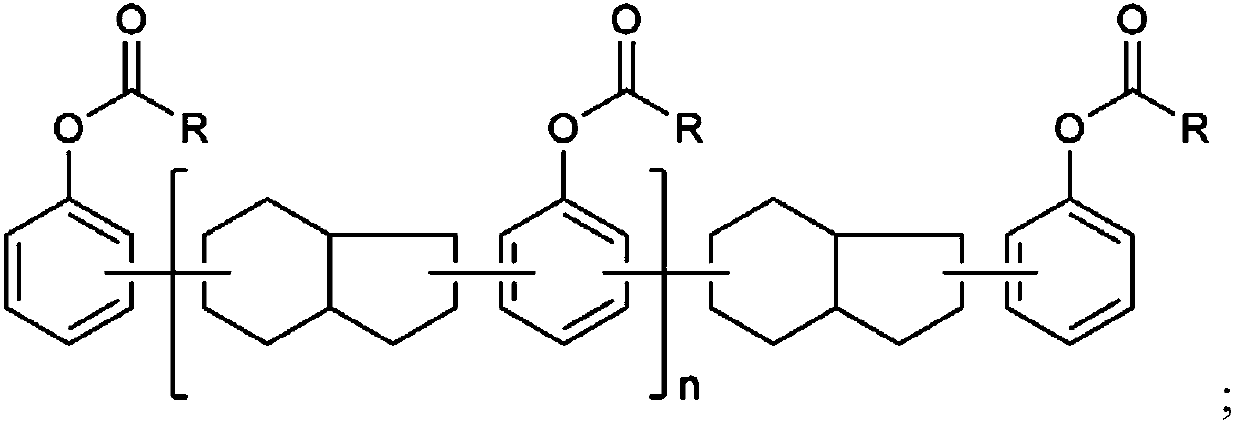

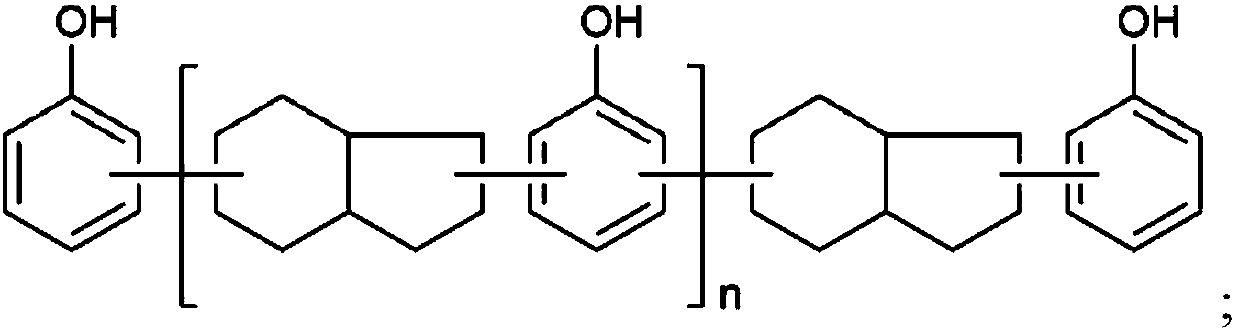

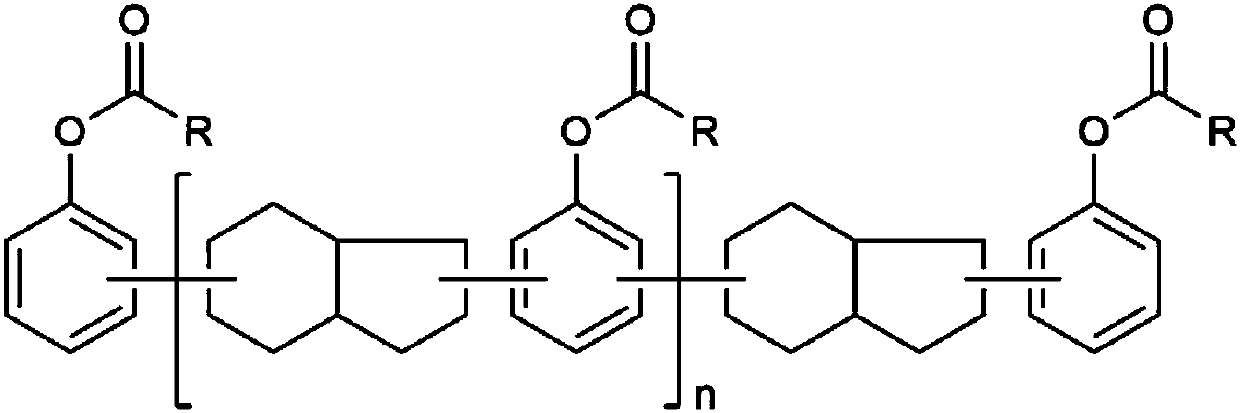

[0034] Wherein, the structural formula of the dicyclopentadiene phenol resin is

[0035]

[0036] In the formula, n includes any integer of 1-4.

[0037] Both phenol and dicyclopentadiene are commonly used industrial raw materials. They have a wide range of sources, are cheap and easy to obtain, and can effectively reduce the production cost of the active ester curing agent, which is beneficial to its large-scale industrial production.

[0038] Further, the above addition reaction is carried out under the action of an acid catalyst. The acid catalyst can stabilize the carbocation intermediate formed by dicyclopentadiene, and the carbocation intermediate acts as an electrophile to attack the benzene ri...

Embodiment 1

[0063] The present embodiment provides a kind of dicyclopentadiene phenol resin, and its preparation method is as follows:

[0064] Add 200 g of phenol and 31 mL of toluene into a four-necked flask equipped with a thermometer, dropping funnel, condenser, and stirrer. Remove toluene and water in the system by azeotropic distillation, then add 0.7mL of BF 3 ·Et 2 O and 1.5mL CCl 4 The mixed solution is heated up to 100°C, and 40g of dicyclopentadiene is slowly added dropwise within 4 to 5 hours, and then kept at a constant temperature for 1 hour. After the reaction is completed, excess phenol is removed by distillation under reduced pressure to obtain the required dicyclopentadiene Phenol resin (light yellow solid, hydroxyl equivalent 170-180mg / g).

Embodiment 2

[0066] The present embodiment provides a kind of active ester solidifying agent, and its preparation method is as follows:

[0067] Add 280g of benzoyl chloride and 1258g of benzene in a four-necked flask equipped with a thermometer, dropping funnel, condenser, and stirrer, and feed nitrogen to dissolve it. Then add the dicyclopentadiene phenol resin that 350g embodiment 1 provides, fully dissolve. The temperature was controlled at 60° C., and 300 g of 20 wt % sodium hydroxide aqueous solution was slowly added dropwise within 3 hours. Then keep the temperature at 60°C and continue to stir for 1h. After the reaction was completed, the aqueous layer was removed by static separation and liquid separation. Then, water was added to the toluene solution of the reactants, stirred and mixed for 15 min, and the water layer was separated and separated. This operation was repeated until the pH of the aqueous layer became 7. Then dehydrate by decanter, obtain the active ester solidify...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com