High-efficiency cadmium selenide-cadmium telluride alloy nanocrystalline solar cell and preparation method thereof

A technology of solar cells and nanocrystals, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of low efficiency, low open-circuit voltage, and short-circuit current, and achieve the effects of simple preparation process, prevention of oxidation, and saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

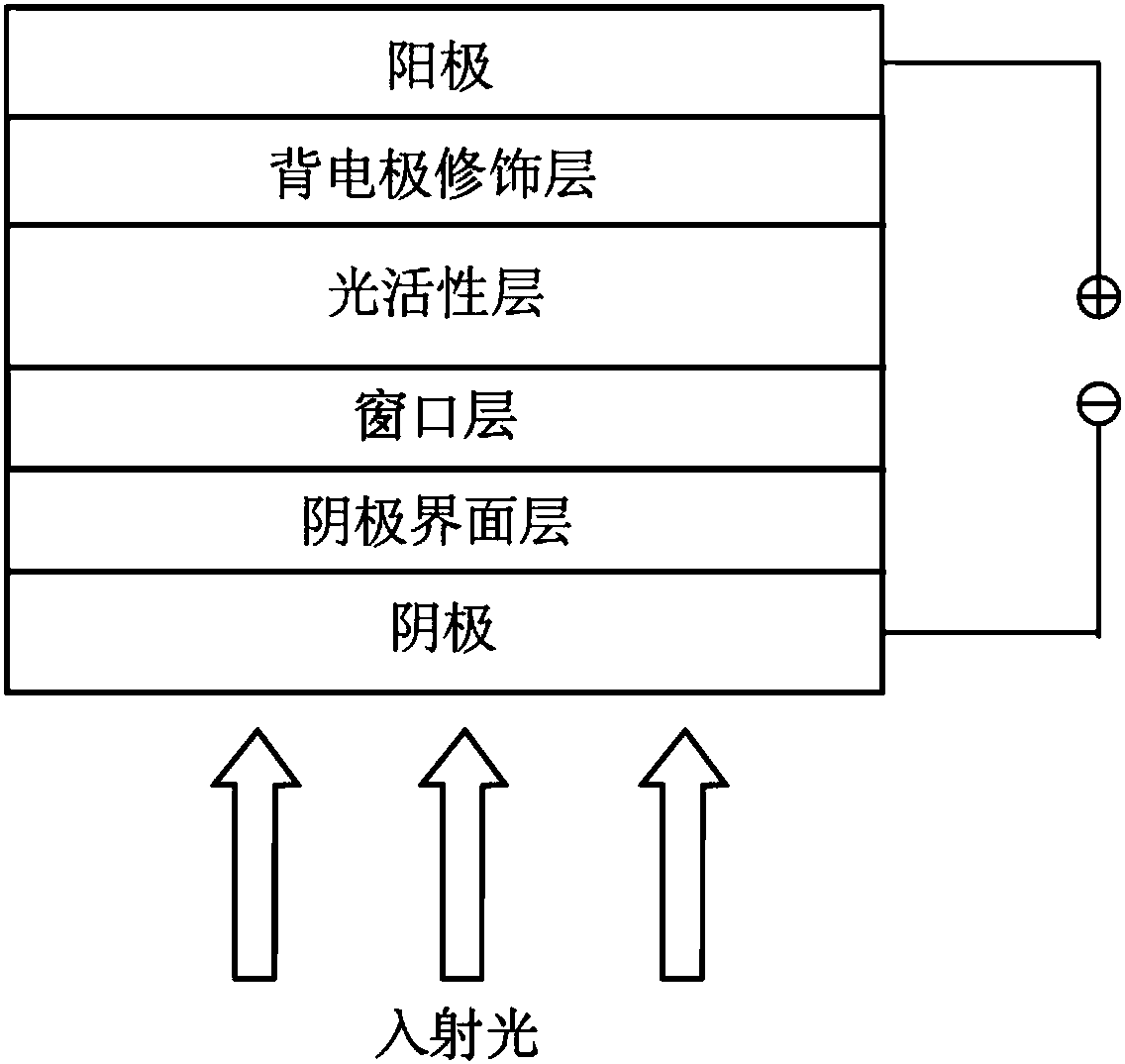

[0033] Example 1: A high-efficiency cadmium selenium telluride alloy nanocrystalline solar cell and its preparation method

[0034] (1) Cleaning of ITO conductive glass substrate: (the specification is 15mm×15mm, the thickness of ITO is 130nm, and its square resistance is 20 ohms / square, purchased from Zhuhai Kaiwei Electronic Components Co., Ltd.) Ultrasonic treatment in toluene, acetone, semiconductor special detergent, deionized water, and isopropanol for 10 minutes to clean the surface of the ITO substrate, and then put the ITO sheet in a constant temperature oven at 80°C for 2 hours to dry.

[0035] (2) Preparation of ZnO layer:

[0036] ① Prepare ZnO sol: put zinc acetate dihydrate (3.2925g), ethanolamine (0.905mL), and ethylene glycol methyl ether (30m1) into a three-neck bottle and seal it. Keep heating in an oil bath at 80°C for 2 hours. (All of the above are analytically pure drugs, purchased from Guangzhou Qianhui Chemical Glass Co., Ltd.), filtered with a 0.45 μm...

Embodiment 2

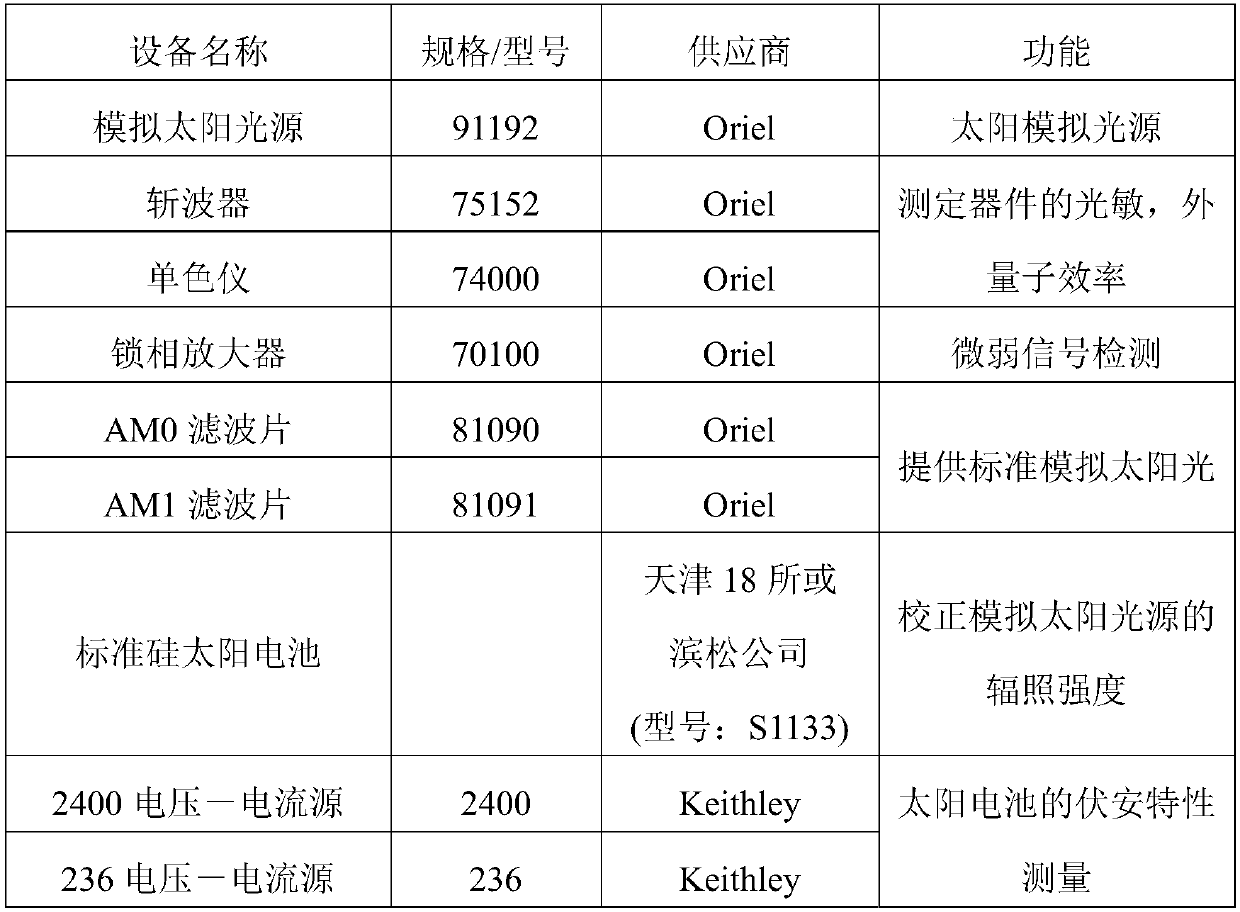

[0047] Embodiment 2: Performance measurement of alloy nanocrystalline solar cell

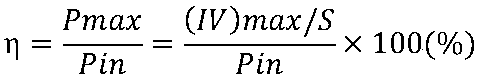

[0048] The determination of the performance parameters of solar cell devices should take sunlight as the test standard. The standard irradiance measured by AM 1.5G in the laboratory is 1000W / m 2 . When using solar simulated light to test the performance of nanocrystalline solar cells, first use standard cells to judge whether the light source meets the irradiance of AM1.5G. Standard silicon solar cells are calibrated, under AM 1.5G standard spectrum, that is, 1000W / m 2 Under the light irradiation of the irradiance, the obtained short-circuit current is 125mA. Once the irradiation intensity is determined, the device can be tested. The solar cell performance test is carried out with the sun simulated light, and the energy conversion efficiency of the solar cell is:

[0049]

[0050] Among them, Pmax is the maximum output power (unit: mW), and Pin is the irradiance (unit: mW / cm 2 ), S is t...

Embodiment 3

[0053] Example 3: Effects of Different TOP-Se Contents in Precursors on the Performance of Nanocrystalline Solar Cells

[0054] The precursors with TOP-Se contents of 0, 10%, 20%, 30%, 40%, 50%, and 60% were selected to prepare CdSe x Te 1-x layer as the photoactive layer, and the device structure is ITO / ZnO / CdSe / CdSe x Te 1-x / MoO x / Au. where CdSe x Te 1-x 400nm thick, CdCl 2 The heat treatment temperature was 350° C., and the time was 15 minutes. Other parameters were implemented as in Example 1. The obtained results are shown in Table 2.

[0055] Table 2

[0056]

[0057]

[0058] It can be seen from Table 2 that when the TOP-Se content is 0, the battery efficiency is 3.07%; when the TOP-Se content is 20%, the battery efficiency is 3.64%, which is better than ITO / ZnO / CdSe / CdTe / MoO x / Au conventional heterojunction solar cells, indicating that the introduction of the alloy layer is beneficial to improve device performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com