Composite thin film, and preparation method and application thereof

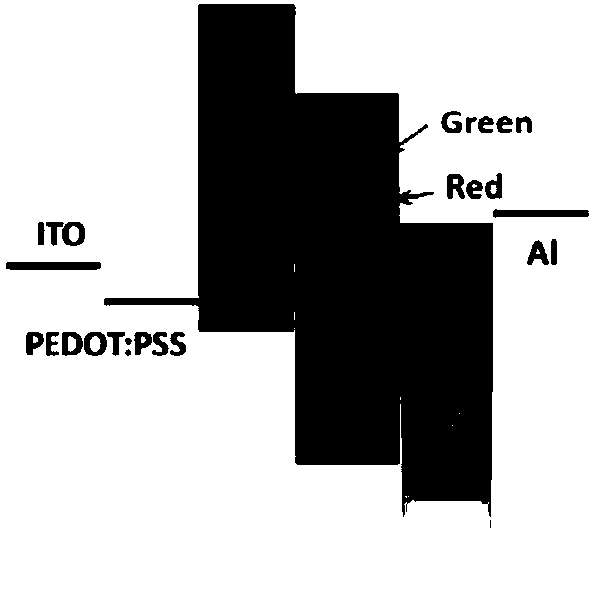

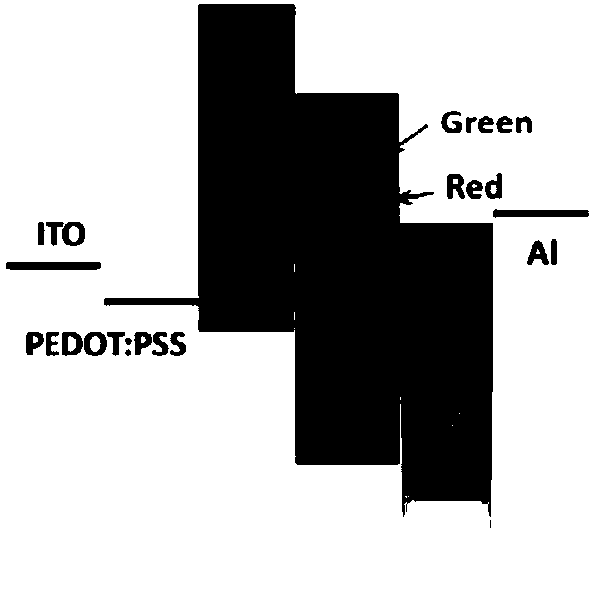

A composite thin film and thin film technology, which is applied in the manufacture of semiconductor/solid-state devices, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of poor energy level matching and high electron injection barriers, and achieve improved device performance. Performance, strong applicability and practicality, and the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

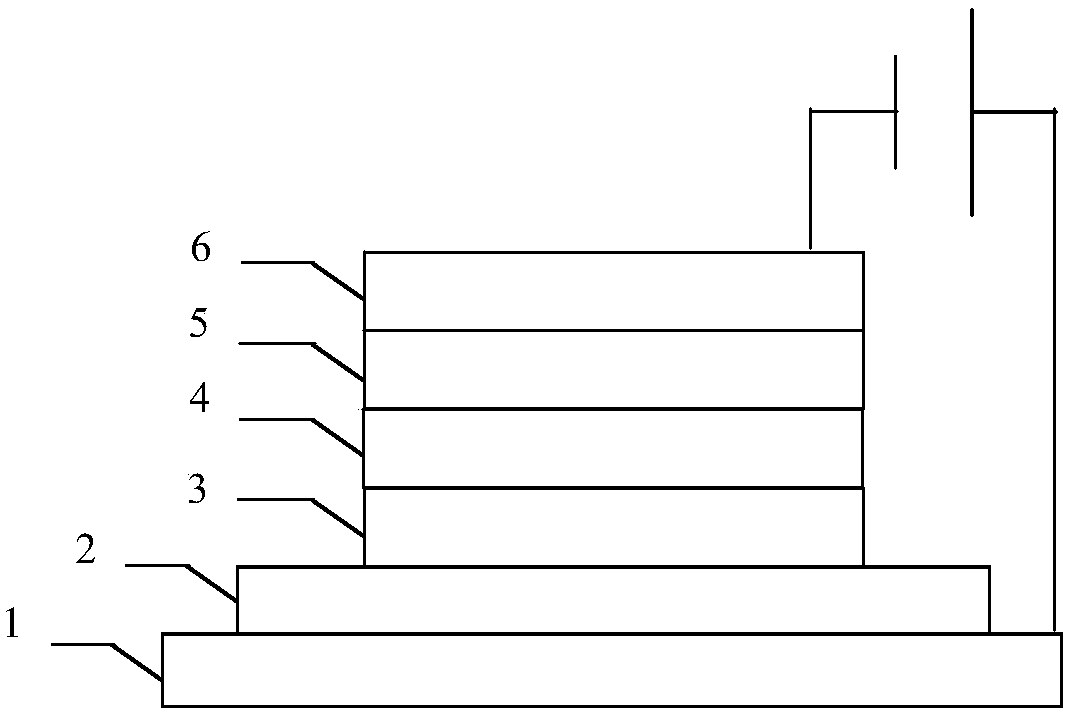

[0041] Correspondingly, an embodiment of the present invention provides a method for preparing a composite film, comprising the following steps:

[0042]S01. prepare the zinc oxide colloid solution containing doping metal ion of different doping concentration, wherein, the ionic radius of described doping metal ion is Zn 2+ 85%-115% of the radius; the conduction band energy level of the oxide doped with metal ions is higher than the conduction band energy level of zinc oxide;

[0043] S02. Provide a substrate, according to the order of the doping concentration of the doped metal ions from small to large or from large to small, sequentially deposit the zinc oxide colloidal solution containing doped metal ions on the substrate, and anneal processing, preparing an N-layer doped with metal ions whose doping concentration is increased or decreased layer by layer, and containing a nano-zinc oxide film doped with metal ions to obtain a composite film, wherein the value range of N sat...

Embodiment 1

[0101] A magnesium ion-doped nano-zinc oxide composite film, the preparation method of which comprises the following steps:

[0102] First, an appropriate amount of zinc acetate and magnesium nitrate is added to 50ml of methanol solvent to form a mixed salt solution with a total concentration of 0.1mol / L, wherein Mg 2+ The doping molar concentration is 1%. Simultaneously, an appropriate amount of potassium hydroxide powder is dissolved in another part of 50ml methanol solvent to form a concentration of lye that is 0.3mol / L. The mixed salt solution was then heated to 50 °C, and potassium hydroxide solution was added dropwise until the molar ratio of hydroxide ions to metal ions was 1.7:1. After the potassium hydroxide solution was dripped, the mixed solution was stirred at 50°C for 2 hours to obtain a uniform transparent solution. Subsequently, a heptane solvent with a volume ratio of 3:1 was added to the homogeneous transparent solution, resulting in a large amount of white ...

Embodiment 2

[0107] A magnesium ion-doped nano-zinc oxide composite film, the preparation method of which comprises the following steps:

[0108] First, an appropriate amount of zinc nitrate and magnesium acetate is added to 50ml ethanol solvent to form a mixed salt solution with a total concentration of 0.1mol / L, wherein Mg 2+ The doping molar concentration is 0%. Simultaneously, an appropriate amount of lithium hydroxide powder is dissolved in another part of 50ml ethanol solvent to form a concentration of lye that is 0.15mol / L. The mixed salt solution was then kept at room temperature, and lithium hydroxide solution was added dropwise until the molar ratio of hydroxide ions to metal ions was 1.8:1. After the potassium hydroxide solution was dripped, the mixed solution was stirred at room temperature for 1 h to obtain a uniform transparent solution. Subsequently, ethyl acetate solvent with a volume ratio of 4:1 was added to the homogeneous transparent solution, resulting in a large amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com