Preparation method of efficient and stable organic polymer solar cell

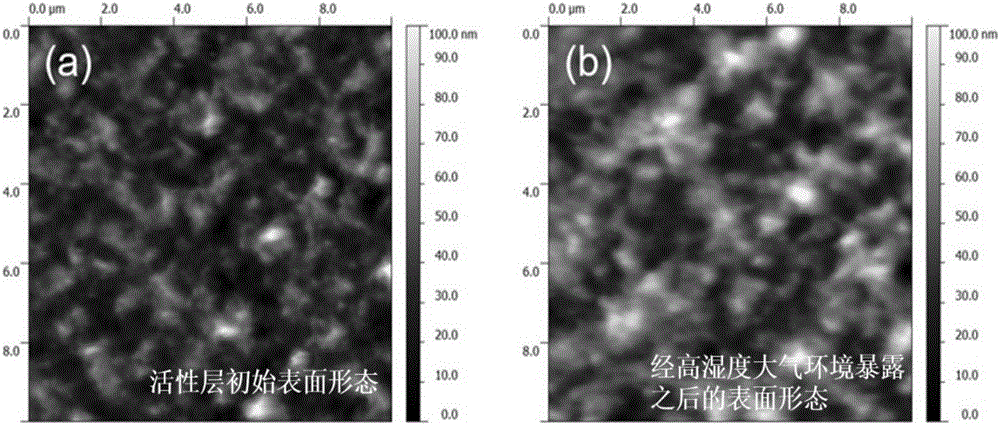

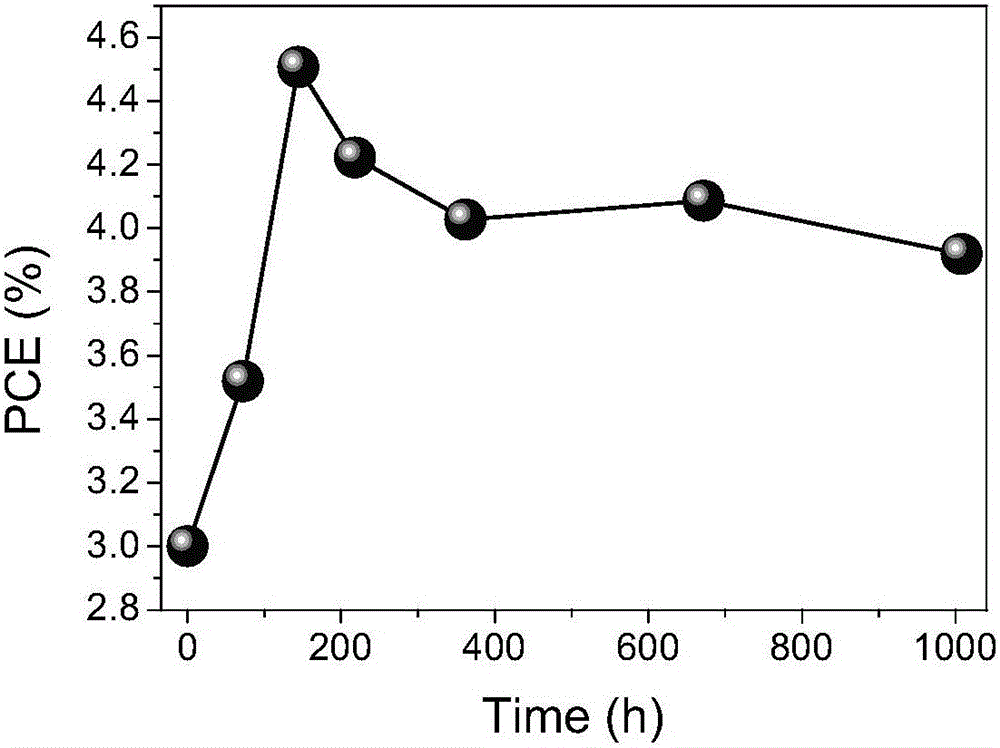

A solar cell and polymer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency, poor stability, rapid interface attenuation, etc., achieve excellent crystallinity, good dispersion, and avoid colloidal particle agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] TiO of the present invention 2 Preparation of nanocrystalline sol:

[0027] 1) Mix 50mL of n-butanol and 1.6mL of nitric acid in a wide-mouth Erlenmeyer flask, stir thoroughly for 10 minutes, and add 5mL of acetic acid at the same time, and wait until the mixture is uniform. At this time, the pH of the system is 0.2, and the system is heated to 40°C;

[0028] 2) Slowly add 24mL tetrabutyl titanate dropwise to the above solution, and stir at 40°C for 40min;

[0029] 3) Add 8 mL of deionized water dropwise to the solution in B at a rate of 0.02 mL / S. After it is hydrolyzed to form a gel, add 100 mL of deionized water and continue stirring at 40°C for 24 hours to obtain a transparent sol;

[0030] 4) Heat the sol to 80°C and stir vigorously for 7 hours to obtain highly dispersed TiO 2 Nanocrystalline;

[0031] 5) The above highly dispersible TiO 2 The nanocrystalline sol was diluted with alcohol 50 times the volume of the sol, and then used.

Embodiment 1

[0033]This example uses a commercial ITO substrate, which has been standard patterned. The ITO substrate was ultrasonically cleaned with acetone, detergent, deionized water and isopropanol for 15 minutes respectively, then dried under hot air, and finally treated with ozone in a UV-ozone machine (UV-Ozone) for 15 minutes. The whole process is to clean the substrate surface.

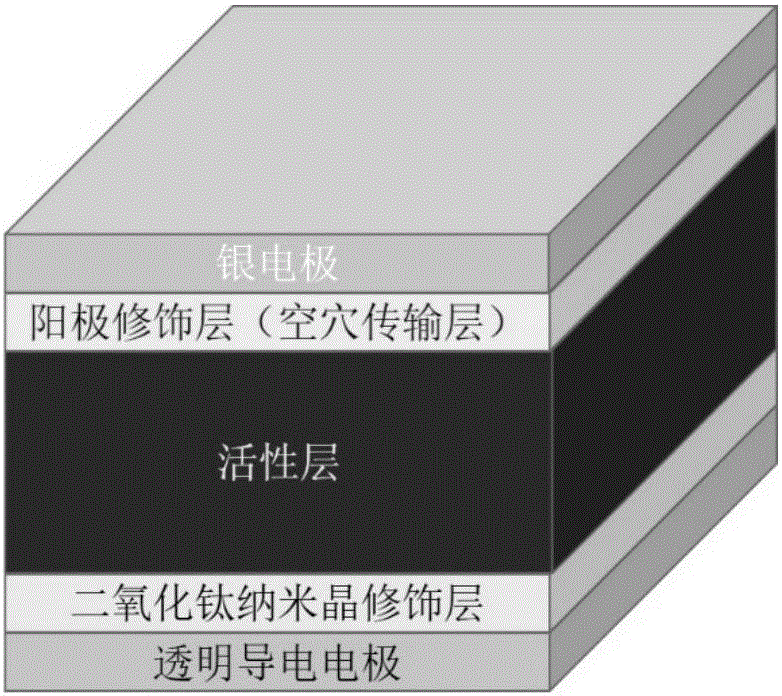

[0034] Will be based on the above method TiO 2 For nanocrystalline sol, spin-coat nanoparticle sol on the treated ITO substrate at 1000 rpm to form an electron transport layer of about 10 nm, and anneal on a 150-degree hot stage for 15 minutes. After it was cooled to room temperature, it was transferred to a glove box, and the previously prepared 1:0.8wt% P3HT:PCBM solution (dissolved P3HT:PCBM in o-dichlorobenzene solution to form a solution) was spin-coated at 1000 rpm. The active layer film was slowly grown in a petri dish for 1.5-3 hours, and then the film was annealed for 15 minutes on a hot stage ...

Embodiment 2

[0043] This example uses a commercial FTO substrate, which has been standard patterned. The FTO substrate was ultrasonically cleaned with acetone, detergent, deionized water and isopropanol for 15 minutes, then dried under hot air, and finally treated with ozone in a UV-ozone machine (UV-Ozone) for 15 minutes. The whole process is to clean the substrate surface.

[0044] The TiO prepared based on the above method 2 For nanocrystalline sol, spin-coat nanoparticle sol on the treated ITO substrate at 1000 rpm to form an electron transport layer of about 10 nm, and anneal on a 100-degree hot stage for 15 minutes. After it was cooled to room temperature, it was transferred to a glove box, and the previously prepared 1:1.5wt% P7BT:PCBM solution was spin-coated at 1700rpm (dissolve P7BT:PCBM in a chlorobenzene solution to form a solution). 3% DIO was added to the active layer film before spin coating, and then the film was left to dry slowly at room temperature. After it dries, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com