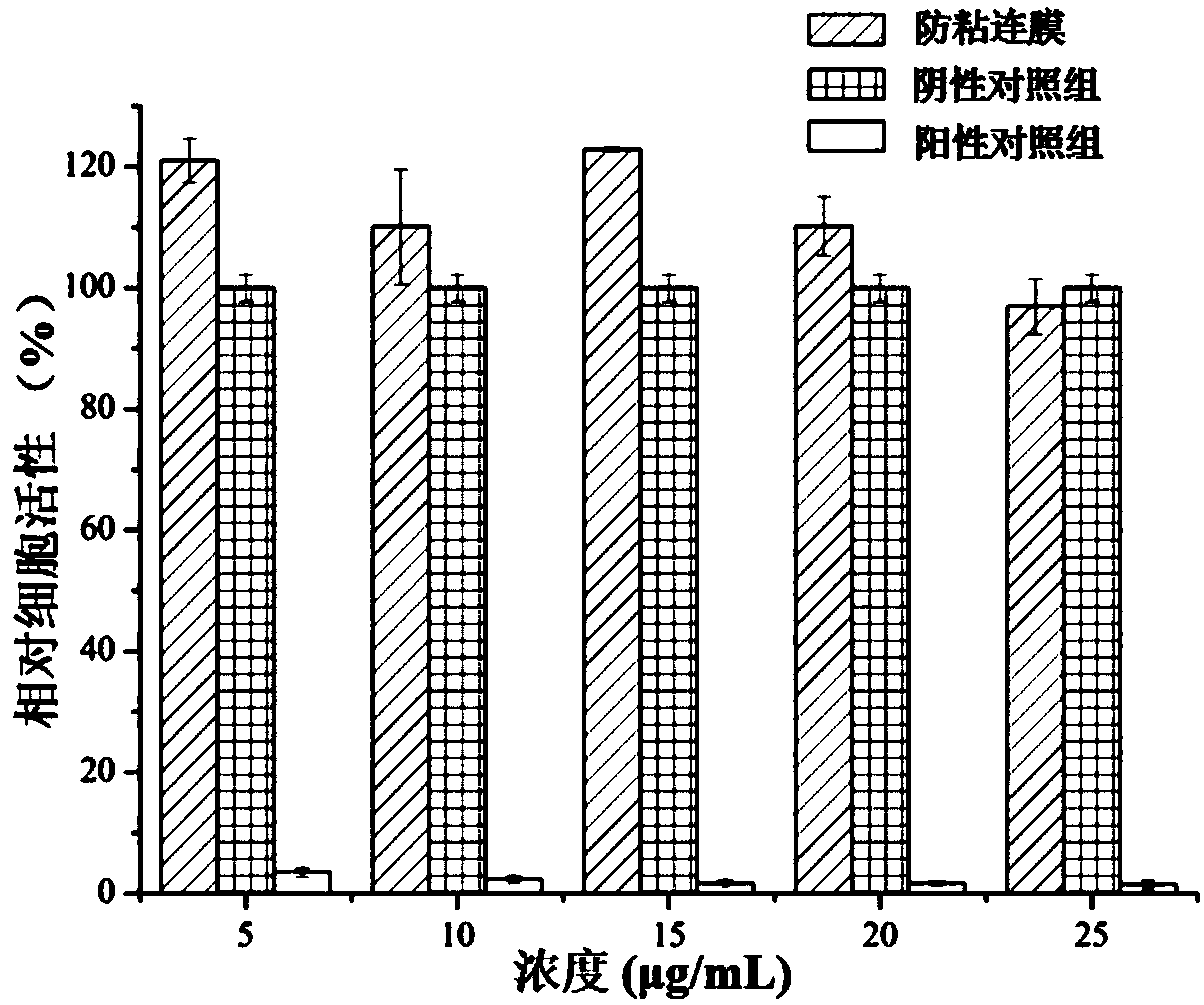

Anti-adhesion material with hemostatic, antibacterial and healing promotion functions and preparation method thereof

An anti-adhesion and functional technology, applied in the field of biomedical materials, can solve the problems of anti-adhesion film that is difficult to degrade, unsuitable for high-incidence wounds with adhesions, small molecule cross-linking agent residues, etc., to achieve easy molding, good clinical application prospects, and promote wound healing healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Dissolve a hyaluronic acid derivative with a molecular weight of 1 million in water at 4°C to obtain 10 mL of a hyaluronic acid derivative solution with a mass-to-volume ratio of 0.05%;

[0046] (2) Dissolve the aminodextran derivative with a molecular weight of 200,000 in water at 4°C to obtain 10 mL of the aminodextran derivative solution with a mass-volume ratio of 50%;

[0047] (3) Mix the hyaluronic acid derivative solution obtained in step (1) with the aminodextran derivative solution obtained in step (2) at a volume ratio of 20:1 under stirring at 4°C, and then mix the above mixed solution It was allowed to stand at -20°C for 48 hours, and then vacuum freeze-dried for 96 hours at a temperature of -45°C and a vacuum of 5 Pascals, thereby dehydrating the material to obtain an anti-adhesion sponge.

Embodiment 2

[0049] (1) Dissolve the sodium alginate derivative with a molecular weight of 800,000 in water at 4°C to obtain 10 mL of a sodium alginate derivative solution with a mass-to-volume ratio of 50%;

[0050] (2) Dissolving an oxidized hyaluronic acid derivative with a molecular weight of 300,000 in water at 4°C to obtain 10 mL of an oxidized hyaluronic acid derivative solution with a mass-to-volume ratio of 0.05%;

[0051] (3) The sodium alginate derivative solution obtained in step (1) and the oxidized hyaluronic acid derivative solution obtained in step (2) were mixed at a volume ratio of 2:8 under stirring at 4 °C, and then 0.2 mL mass fraction was added. A 0.5% sorbitol solution was slowly added dropwise to the mixed solution and allowed to stand at 4°C for 30 minutes. Subsequently, the above mixed solution added with sorbitol was allowed to stand at -20°C for 48h, and then vacuum freeze-dried for 96h at a temperature of -45°C and a vacuum degree of 5 Pascals, and finally an a...

Embodiment 3

[0053] (1) Dissolve a cellulose derivative with a molecular weight of 600,000 in water at 4°C to obtain 10 mL of a cellulose derivative solution with a mass-volume ratio of 3%;

[0054] (2) Dissolving the aminated Bletilla striata polysaccharide derivative with a molecular weight of 300,000 in water at 4° C. to obtain 10 mL of a 6% mass-volume ratio of the aminated Bletilla striata polysaccharide derivative solution;

[0055] (3) Mix the cellulose derivative solution obtained in step (1) with the amino acid Bletilla striata polysaccharide derivative solution obtained in step (2) at a volume ratio of 5:5 under stirring at 4°C, and then the mixed solution was changed from 300 Filter through mesh sieve, defoaming under reduced pressure, and cast film after standing at room temperature to obtain an anti-adhesion film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com