Nano cerium manganese oxide/activated carbon composite material for room temperature oxidation of formaldehyde and preparation method thereof

A technology of composite materials and oxides, applied in the field of nano-cerium manganese oxide/activated carbon composite materials and its preparation, can solve the problems of easy detachment and deactivation, low loading capacity, poor binding force, etc., to improve hydrophobic performance and prevent agglomeration , the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

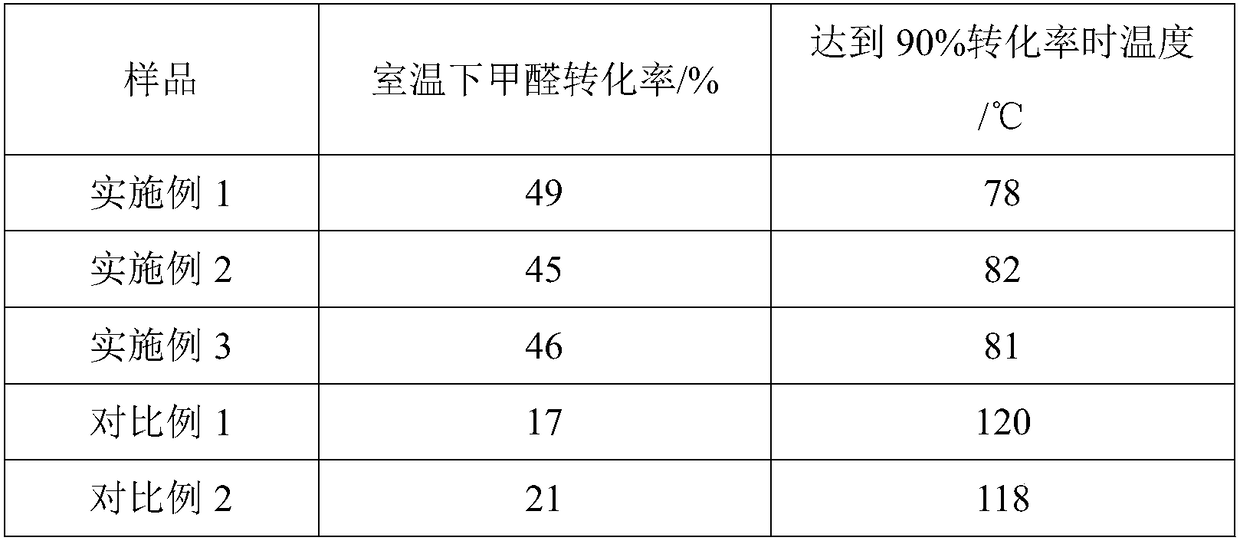

Examples

Embodiment 1

[0050] The preparation method of this embodiment is as follows:

[0051] Screen coconut shell granular activated carbon (1000mg / g iodine value) with mesh number 80-150, soak it in the mixed solution of 65-70wt% nitric acid and 98wt% sulfuric acid, and pretreat it at 80°C for 4h. After filtration, wash with deionized water several times until the pH is between 6 and 7, and dry in an oven at 120°C for 8 hours.

[0052] Get above-mentioned pretreated activated carbon 100g and polyvinylpyrrolidone 25g and add into deionized water under stirring (1000r / min). Then add 16g of melamine, stir at room temperature for 1 hour, and then ultrasonically treat at 60°C for 3 hours to obtain a brown gel. After standing for 1 hour, filter off the supernatant, wash with distilled water for 3 to 5 times, and transfer to an oven at 100°C after filtering. 1h to get xerogel. Then calcined in a muffle furnace at 500°C for 3h, and cooled to room temperature to obtain modified activated carbon particl...

Embodiment 2

[0055] The preparation method of this embodiment is as follows:

[0056] Coal-based granular activated carbon with a mesh number of 80-150 (iodine value 1200mg / g) was screened, soaked in a mixed solution of 65-70wt% nitric acid and 98wt% sulfuric acid, and pretreated at 80°C for 4 hours. After filtration, wash with deionized water several times until the pH is between 6 and 7, and dry in an oven at 120°C for 8 hours.

[0057] Take 100 g of the above-mentioned pretreated activated carbon and 20 g of polyethyleneimine and add them into deionized water under stirring (1000 r / min). Then add 16g of urea, stir at room temperature for 1 hour, and then ultrasonically treat at 60°C for 3 hours to obtain a brown gel. After standing for 1 hour, filter off the supernatant, wash with distilled water for 3 to 5 times, and transfer to an oven at 100°C after filtering. 1h to get xerogel. Then calcined in a muffle furnace at 500°C for 3h, and cooled to room temperature to obtain modified act...

Embodiment 3

[0060] Screen coconut shell granular activated carbon (1000mg / g iodine value) with mesh number 80-150, soak it in the mixed solution of 65-70wt% nitric acid and 98wt% sulfuric acid, and pretreat it at 80°C for 4h. After filtration, wash with deionized water several times until the pH is between 6 and 7, and dry in an oven at 120°C for 8 hours.

[0061] Get the above-mentioned pretreated activated carbon 100g and acrylic acid maleic anhydride copolymer 25g and add them into deionized water under stirring (1000r / min). Then add 20g of biuret, stir at room temperature for 1 hour, and then ultrasonically treat at 60°C for 3 hours to obtain a brown gel. After standing for 1 hour, filter off the supernatant, wash with distilled water for 3 to 5 times, and transfer to 100°C after filtration. Dry gel was obtained in oven for 1h. Then calcined in a muffle furnace at 500°C for 2h, and cooled to room temperature to obtain modified activated carbon particles.

[0062] 1.58g KMnO 4 (0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com