Modification method of ts-1 and its application in solvent-free catalyzed preparation of pyruvate from lactate

A technology for catalyzing lactate and TS-1, which is applied in the preparation of carboxylate, catalyst activation/preparation, preparation of organic compounds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]In this example, the modification of commercialized TS-1 and the catalytic oxidation of ethyl lactate to prepare ethyl pyruvate:

[0039] The modification process of TS-1 went through the first water vapor treatment, the second crystallization, the second water vapor treatment and the washing liquid treatment in sequence.

[0040] The first steam treatment: Take 1.0 g of commercial TS-1 and place it in a fixed-bed reactor, raise the temperature to 500°C, and pass 100% steam for 2 hours. Then the feed of water vapor was stopped, and the temperature of the reactor was lowered to room temperature under nitrogen atmosphere.

[0041] Secondary crystallization: take out TS-1, and grind it with 0.5 g of tetrapropylammonium bromide in a mortar for 3 hours. Next, the ground solid was transferred to a polytetrafluoroethylene-lined crystallization kettle, and 10 mL of propanol solvent was added and stirred for 30 minutes. After sealing the crystallization kettle, let it stand at ...

Embodiment 2

[0049] In this example, the modification of commercialized TS-1 and the catalytic oxidation of ethyl lactate to prepare ethyl pyruvate:

[0050] In the modification method, except that the 0.1M dilute sulfuric acid was replaced by 0.1M phosphoric acid during the washing solution treatment, other modification conditions were the same as in Example 1.

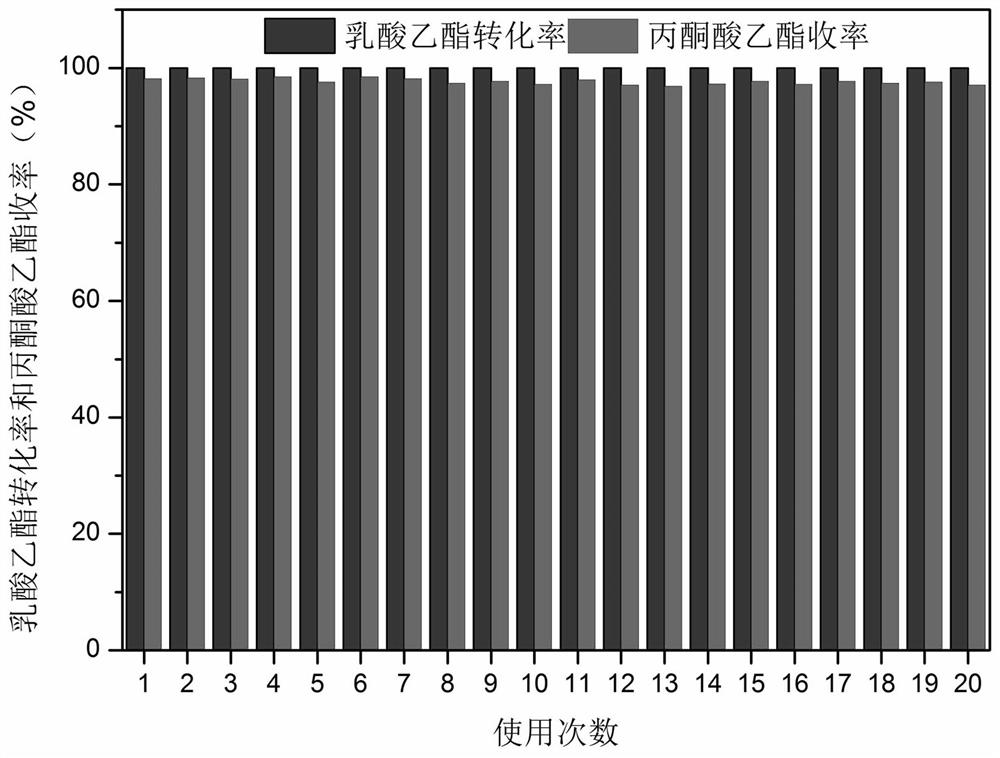

[0051] The modified TS-1 was used to catalyze the oxidation of ethyl lactate to prepare ethyl pyruvate under solvent-free conditions, and the reaction conditions were exactly the same as in Example 1. The reaction results are shown in Table 1.

Embodiment 3

[0053] In this example, the modification of commercialized TS-1 and the catalytic oxidation of ethyl lactate to prepare ethyl pyruvate:

[0054] In the modification method, except that the hydrogen peroxide with a mass fraction of 30% was replaced by 0.1M sodium hypochlorite in the washing liquid treatment process, other modification conditions were the same as in Example 1.

[0055] The modified TS-1 was used to catalyze the oxidation of ethyl lactate to prepare ethyl pyruvate under solvent-free conditions, and the reaction conditions were exactly the same as in Example 1. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com