Preparation method of compound modified starch adhesive

A starch adhesive and composite technology, which is used in the preparation of starch adhesives, animal glue or gelatin, and adhesives, etc., can solve the problems of poor fluidity, low bonding strength, and poor water resistance of starch adhesives. Stable performance, product quality, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

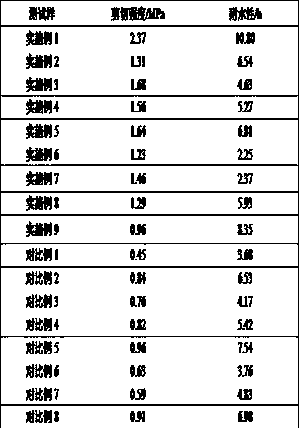

Examples

Embodiment 1

[0010] 1) 1) First weigh 5 parts by weight of SSZ-13 molecular sieve nanoparticles and slowly add it to 25 parts by weight of an acidic reagent with a weight percentage of 56%. After magnetic stirring for 30 minutes, add 12 parts by weight of deionized water and 2 parts of Fe2O3 powder Mix, put the sample into the centrifuge, centrifuge at 3800r / min for 6~8min, pour off the supernatant, then add 12 parts by weight of deionized water, put it in the centrifuge and centrifuge for 6~8min, repeat the above operation for 4 After ~5 times, put the sample into a dialysis bag and soak it in distilled water, change the water 3~4 times a day, dialyze for 2~3 days, let stand at room temperature for more than 1h, calcinate at 600°C for 5h, then filter, wash and dry to get Modified Fe-SSZ-13 molecular sieve nanoparticles for standby;

[0011] 2) Add 35 parts by weight of cornstarch and 50 parts by weight of 20% ethanol aqueous solution into a 500ml two-necked microwave flask, stir and shake...

Embodiment 2

[0016] It is exactly the same as Example 1, except that 2 parts by weight of modified Fe-SSZ-13 molecular sieve nanoparticles, 0.35 parts by weight of NaClO, and 28 parts by weight of furfural resin are added.

Embodiment 3

[0018] It is exactly the same as Example 1, except that 6 parts by weight of modified Fe-SSZ-13 molecular sieve nanoparticles, 1.05 parts by weight of NaClO, and 42 parts by weight of furfural resin are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com