Preparation method of surface-enhanced Raman substrate and application of the substrate to detection of animal viruses

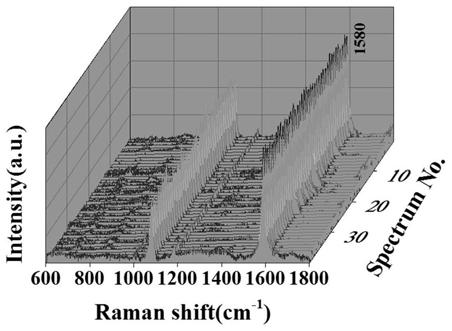

A surface-enhanced Raman and Raman substrate technology, applied in the field of Raman spectroscopy and nanomaterials, can solve the problems of different SERS substrate performance, irregular surface, poor signal enhancement effect and reproducibility, etc., to achieve enhanced Raman Effective, low cost, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

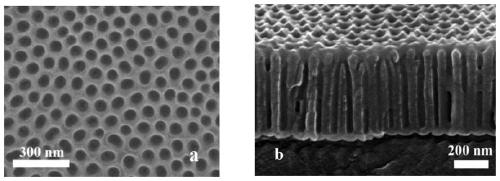

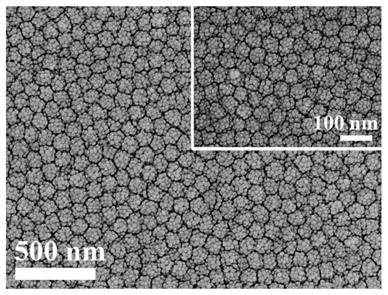

[0029] see figure 1 As shown, the embodiment of the present invention provides a method for preparing a surface-enhanced Raman substrate, comprising the following steps:

[0030] S1. Cut the ultra-pure aluminum into 2cm×2cm sheets, flatten it with a tablet machine, anneal it under the protection of high-purity nitrogen at a temperature of 500°C for 3-5 hours, and then put it into acetone for ultrasonic degreasing After 20 minutes, soak in NaOH solution with a concentration of 1M for a while, take it out, rinse it with ultrapure water, and dry it. (In this step, the size of the ultrapure aluminum sheet, the concentration of NaOH, the annealing temperature and the time can all be selected according to actual needs.)

[0031] S2. Use ordinary aluminum sheet as cathode and pretreated ultra-pure aluminum sheet as anode, seal one side of ordinary aluminum sheet and ultra-pure aluminum sheet and put it into the electrolytic cell, use magnetic stirring, and the oxidation voltage is 1...

Embodiment 2

[0054] S201. Use ordinary aluminum sheets as cathodes and pretreated ultra-pure aluminum sheets as anodes, seal one side of ordinary aluminum sheets and ultra-pure aluminum sheets and put them into the electrolytic cell, use magnetic stirring, and use oxalic acid with a concentration of 0.1M The solution is used as an electrolyte, oxidized for 6 hours under the conditions of oxidation voltage of 30V, oxidation current of 20mA, and temperature of 5°C, and then placed in a temperature of 40°C, containing CrO at a concentration of 3wt%. 3 and a concentration of 6% H 3 PO 4 The oxide layer was removed by immersing in the mixed solution for 10 minutes to obtain a preliminary porous structure template.

[0055] S202. Use the preliminary porous structure template as an anode, put it into an oxalic acid solution with a concentration of 0.1M, oxidize it for 20 minutes under the conditions of an oxidation voltage of 30V and a temperature of -5°C, and put it into H at a temperature of 2...

Embodiment 3

[0059] S301. Use ordinary aluminum sheets as cathodes and pretreated ultra-pure aluminum sheets as anodes, seal one side of ordinary aluminum sheets and ultra-pure aluminum sheets and put them into the electrolytic cell, use magnetic stirring, and use sulfuric acid with a concentration of 0.5M The solution is used as an electrolyte, oxidized for 3 hours under the conditions of oxidation voltage of 190V, oxidation current of 3mA, and temperature of 0°C, and then placed in a temperature of 70°C, containing CrO with a concentration of 1wt%. 3 and a concentration of 6% H 3 PO 4 soaked in the mixed solution for 40 minutes to remove the oxide layer and obtain a preliminary porous structure template.

[0060] S302. Use the preliminary porous structure template as an anode, put it into a sulfuric acid solution with a concentration of 0.5M, oxidize it for 20 minutes under the conditions of an oxidation voltage of 150V and a temperature of 10°C, and put it into H at a temperature of 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com