Parathion-methyl detection method

A methyl parathion and detection method technology, applied in the field of food safety detection, can solve the problems of high detection cost, long processing time, complicated operation, etc., and achieve the effects of high detection sensitivity, wide application and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

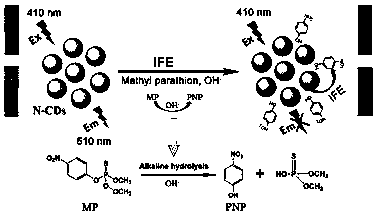

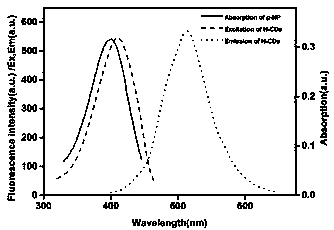

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh 0.27g catechol and dissolve it in 25ml ultrapure water, then add 300ul ethylenediamine, transfer to a 50ml reaction kettle after ultrasonication for 5min, hydrothermally react at 180°C for 12h, then cool naturally to 20~25°C , centrifuged at 10,000 rpm for 10 min to obtain a yellow N-CDs solution, which was dialyzed with a 500 Da dialysis bag for 48 h, diluted 10 times with deionized water, and stored in a refrigerator at 4 °C until use.

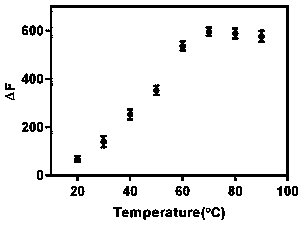

[0035] 2) Take the N-CDs solution prepared in step 1), and divide it into 2 groups on average, 8 parts in each group, 30uL in each part, add 2.92mL of PBS buffer solution (0.2M, pH=12) to each part of the N-CDs solution and mix well , to make the mixed solution alkaline, and then add 50 μl of MP solution with a concentration of 150 ppm to one of the mixed solutions, and no MP solution was added to the other mixed solution. Each of the above mixed solutions was incubated at 20°C, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C and 90°C for...

Embodiment 2

[0038] The test method is the same as in Example 1, wherein the incubation temperature is 70° C., and the incubation time is set as variables, which are 5 min, 10 min, 15 min, 20 min, 25 min, 30 min and 35 min, respectively. The result is as Figure 4 shown.

[0039] from Figure 4 It can be seen that as the incubation time increases, the fluorescence quenching intensity of the same concentration and volume of MP solution is also continuously enhanced. When the incubation time is more than 25min, the fluorescence quenching intensity does not change much, that is, the incubation time is 25min , the methyl parathion in the mixed solution was completely hydrolyzed into nitrophenol.

Embodiment 3

[0041] The test method is the same as in Example 1, wherein the incubation temperature is 70° C., and the pH value of the PBS buffer solution is variable, which are 7, 8, 9, 10, 11, 12, 13 and 14, respectively. The result is as Figure 5 shown.

[0042] from Figure 5It can be seen that as the pH value of the buffer solution increases continuously, the fluorescence quenching intensity of the MP solution with the same concentration and volume is also continuously enhanced. When the pH value of the buffer solution is greater than 12, the fluorescence quenching intensity continues to increase. The weakening, that is, when the pH value of the buffer solution is 12, the effect of hydrolyzing methyl parathion into nitrophenol in the mixed solution is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com