Building decoration material with formaldehyde purification function and preparation method of building decoration material

A building decoration material and formaldehyde purification technology, applied in the field of air purification, can solve the problems that cannot be eliminated, achieve the effect of enhancing the ability to remove formaldehyde, improving efficiency, and the preparation process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

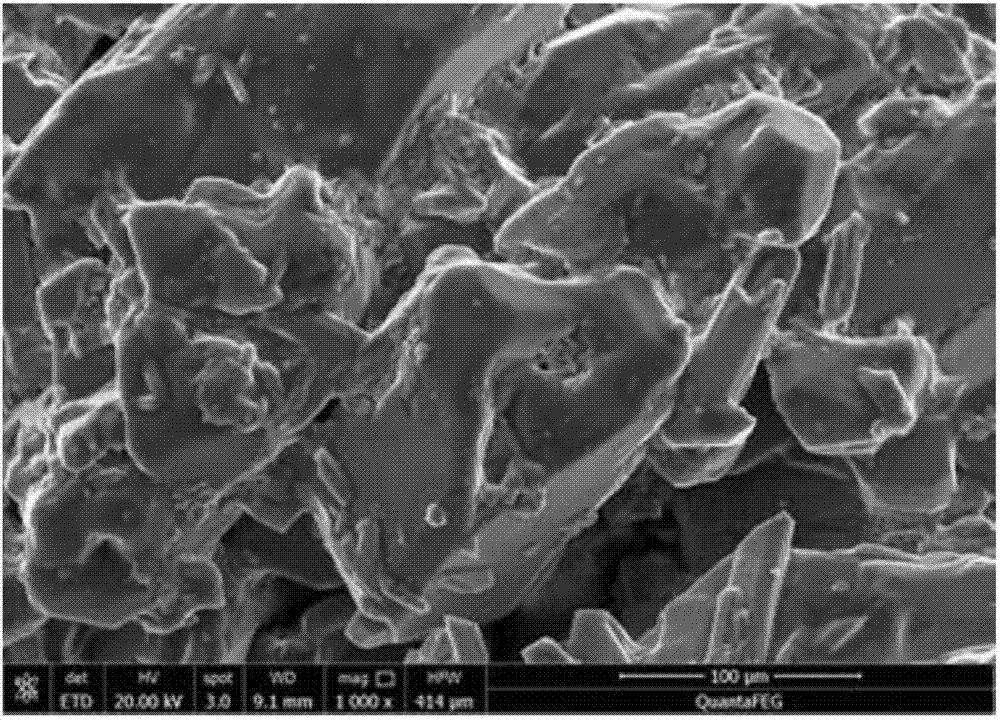

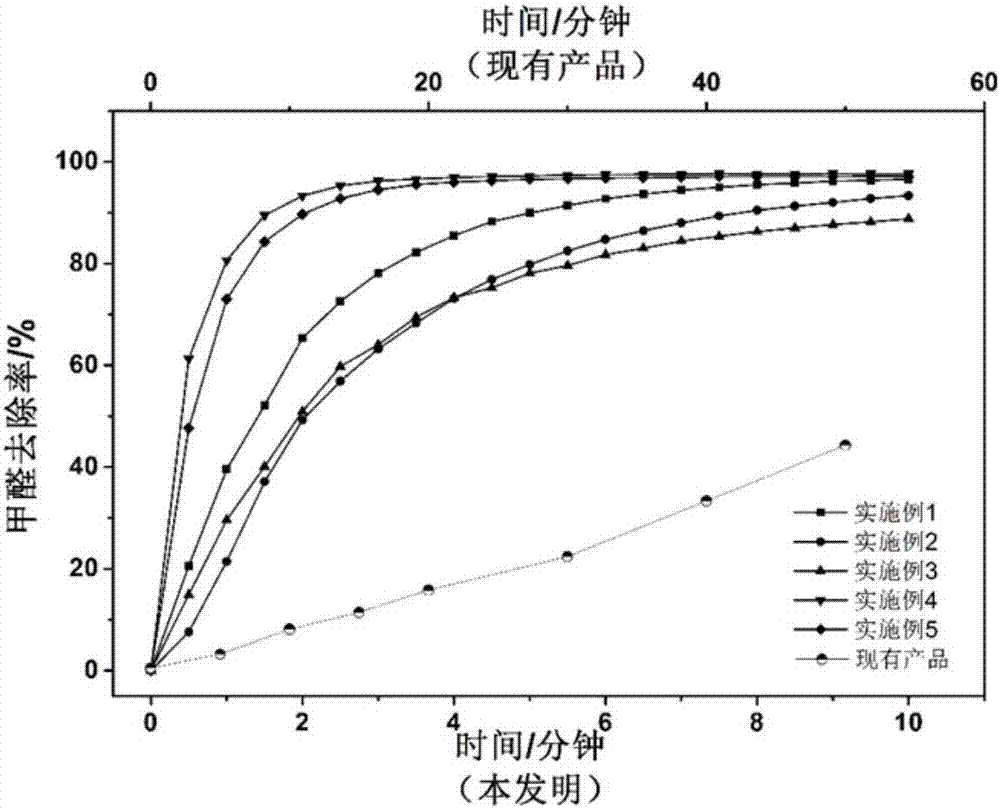

[0038] Example 1: Preparation of gypsum material with formaldehyde purification function.

[0039] 1) Using a ball mill, 2 g of polyvinylpyrrolidone and 1 g of polyethylene glycol were ball milled and mixed at a speed of 300 rpm for 60 minutes to obtain mixture A;

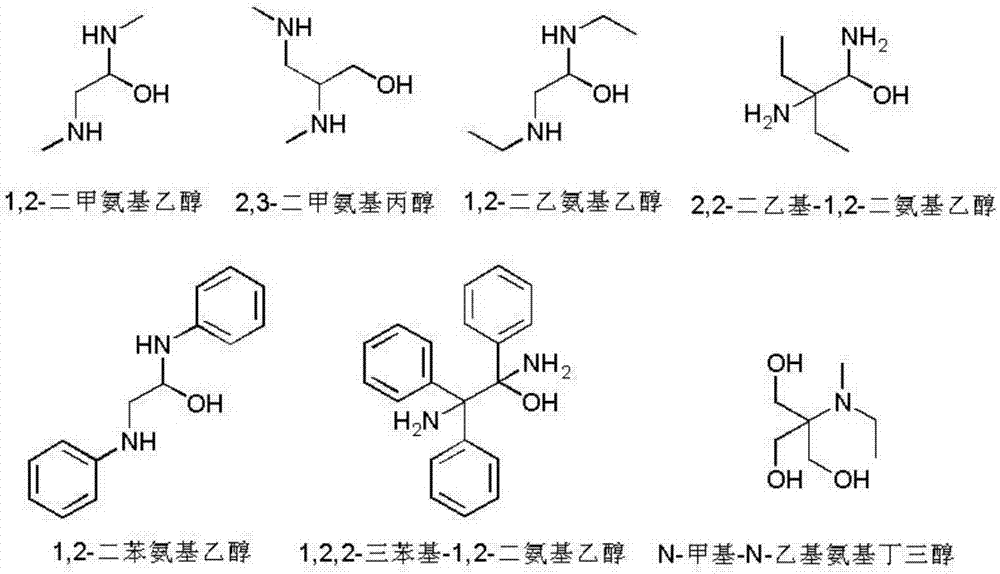

[0040]2) Add 1g of titanium dioxide, 1g of tin dioxide, 1g of silicon dioxide, 2g of magnesium oxide, 1g of activated carbon, 1g of calcium chloride, 1g of sodium carbonate and 4g of 1,2-dimethylaminoethanol to the mixture obtained in step 1) In A, ball mill and mix for 120 minutes at a speed of 300 rpm to obtain mixture B, which is filtered through a 200-mesh filter screen to obtain a formaldehyde scavenger;

[0041] 3) Using a mixer, mix 100g of gypsum powder and 0.5g of modified starch to obtain a mixture C;

[0042] 4) Using mechanical stirring, 1 g of polyvinyl alcohol, 0.6 g of lignocellulose, 65 g of water and 1 g of the formaldehyde scavenger obtained in step 2) were evenly stirred to obtain a mixture D; ...

Embodiment 2

[0044] Example 2: Preparation of putty material with formaldehyde purification function.

[0045] 1) Using a ball mill, 10 g of polyvinylpyrrolidone and 6 g of polyacrylamide were ball milled and mixed at a speed of 800 rpm for 30 minutes to obtain mixture A;

[0046] 2) Add 7g of titanium dioxide, 7g of tin dioxide, 7g of silicon dioxide, 6g of magnesium oxide, 13g of activated carbon, 9g of calcium chloride, 13g of sodium sulfite and 42g of 2,3-dimethylaminopropanol to the mixture obtained in step 1) In A, ball mill and mix for 30 minutes at a speed of 800 rpm to obtain mixture B, which is filtered through a 200-mesh filter screen to obtain a formaldehyde scavenger;

[0047] 3) Using a mixer, mix 100g of putty powder and 1g of modified starch to obtain mixture C;

[0048] 4) Using mechanical stirring, 1.5 g of ethylene acetate, 1 g of lignocellulose, 75 g of water and 20 g of the formaldehyde scavenger obtained in step 2) were evenly stirred to obtain a mixture D;

[0049]...

Embodiment 3

[0050] Example 3: Preparation of clay material with formaldehyde purification function.

[0051] 1) Using a ball mill, 4 g of polyvinylpyrrolidone and 2 g of carboxymethyl cellulose were ball milled and mixed at a speed of 500 rpm for 40 minutes to obtain a mixture A;

[0052] 2) Add 6g of titanium dioxide, 6g of tin dioxide, 5g of silicon dioxide, 3g of magnesium oxide, 3g of activated carbon, 2g of calcium chloride, 3g of sodium bicarbonate and 10g of 1,2-diphenylaminoethanol to the obtained In mixture A, ball mill and mix at a speed of 500 rpm for 80 minutes to obtain mixture B, which is filtered through a 200-mesh filter to obtain a formaldehyde scavenger;

[0053] 3) Using a mixer, mix 100g clay and 0.8g modified starch to obtain mixture C;

[0054] 4) Using mechanical stirring, 1.2g of polyurethane, 0.8g of lignocellulose, 70g of water and 5g of the formaldehyde scavenger obtained in step 2) were evenly stirred to obtain mixture D;

[0055] 5) Add the mixture D obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com