Preparation method and application of visible-light photo-catalyst

A photocatalyst and visible light technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of no practical value and low catalytic activity, and achieve the improvement of photocatalytic hydrogen production rate, catalyst stability, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

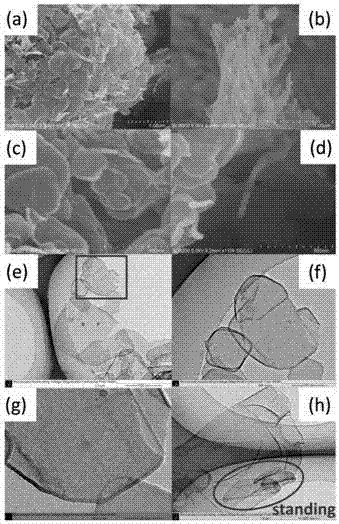

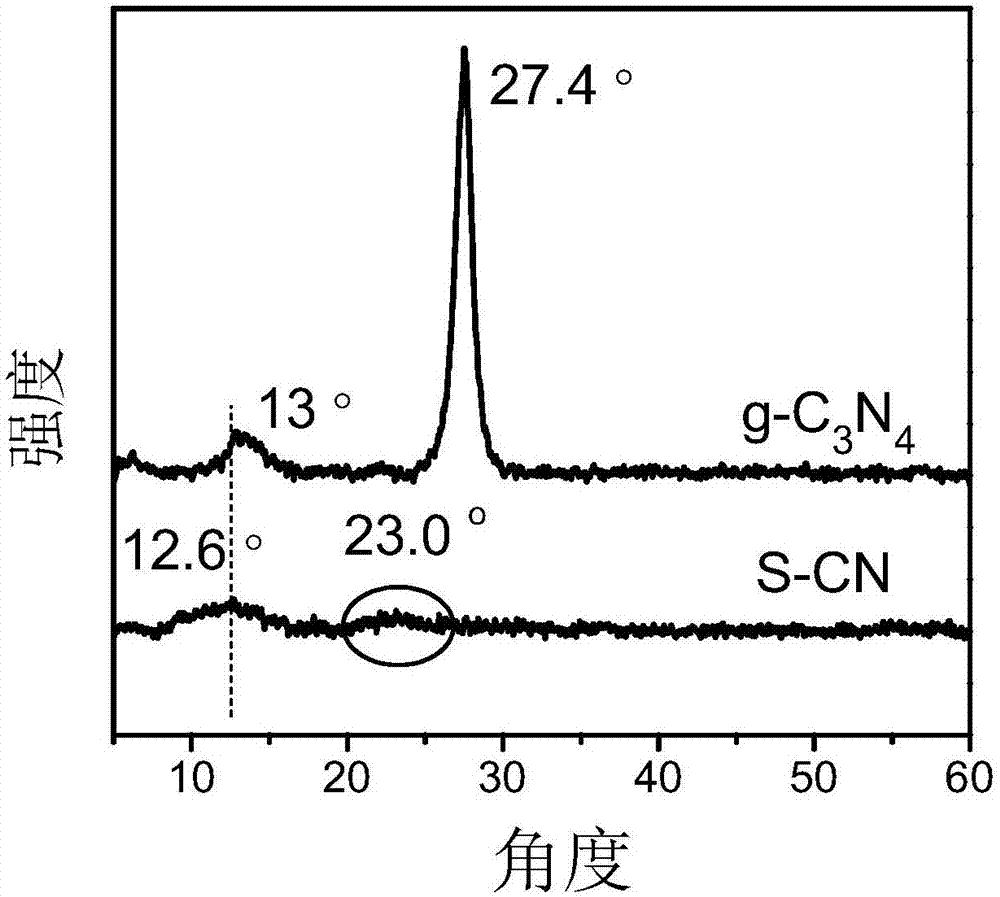

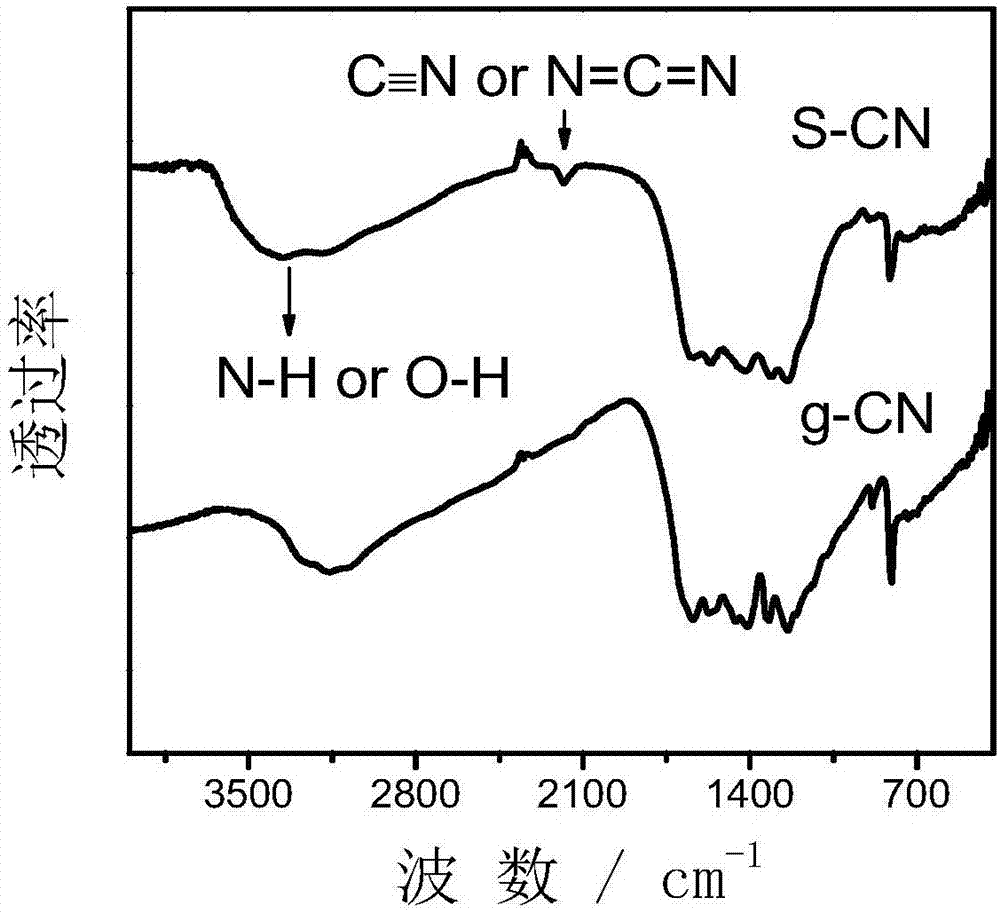

[0024] The cyanuric chloride and sulfur simple substance S 8 According to the mass ratio of 3:15 mixed and fully ground for 3 hours to obtain a solid powder, the obtained solid powder requires cyanuric chloride and sulfur elemental S 8 Mix evenly, preferably with a particle size of 60 mesh or more; put the solid powder in a muffle furnace, and treat it at 450°C for 3 hours under a nitrogen atmosphere, and keep the nitrogen flow at 6L min -1 , naturally cooled to room temperature and then taken out to obtain the product and weigh it.

Embodiment 2

[0026] The cyanuric chloride and sulfur simple substance S 8 According to the mass ratio of 4:15 mixed and fully ground for 3 hours to obtain a solid powder, the obtained solid powder requires cyanuric chloride and sulfur element S 8 Mix evenly, preferably with a particle size of 60 mesh or more; put the solid powder in a muffle furnace, and treat it at 550°C for 4 hours under a nitrogen atmosphere, and keep the nitrogen flow at 6L min -1 , naturally cooled to room temperature and then taken out to obtain the product and weigh it.

Embodiment 3

[0028] The cyanuric chloride and sulfur simple substance S 8 According to the mass ratio of 4:10 mixed and fully ground for 3 hours to obtain a solid powder, the obtained solid powder requires cyanuric chloride and sulfur elemental S 8 Mix evenly, preferably with a particle size of 60 mesh or more; put the solid powder in a muffle furnace, and treat it at 450°C for 3 hours under a nitrogen atmosphere, and keep the nitrogen flow at 6L min -1 , naturally cooled to room temperature and then taken out to obtain the product and weigh it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com