Industrial production method for dried sweet potato leaf products

A production method and technology of sweet potato leaves are applied in the directions of bacteria used in food preparation, food preservation, food drying, etc., and can solve the problems of weak aroma, poor palatability, dull color, etc., and achieve good flavor, easy storage, and improved flavor. and palatability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

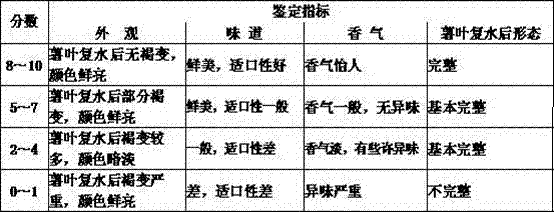

Embodiment 1

[0015] Embodiment 1, finely cut the top stem and leaf of sweet potato below 8cm in sweet potato base, remove its rotten blade, by washing tank with flowing water, silt, worm are washed off. Blanch the washed potato leaves with hot water at 100°C for 2 minutes, and immediately rinse with cold water after taking them out. Put the cooled potato leaves in a stirring fermenter, inoculate with 3% activated Lactobacillus plantarum, add 3% edible salt, and stir slowly. The fermentation temperature was controlled within the range of 30°C, and the fermentation was carried out for 2 days. Transfer the fermented potato leaves to a centrifuge and centrifuge at 2000r / min for 5min. Spread the centrifuged potato leaves flat in a drying frame with a thickness of 2 cm. Use an electric hot air tunnel dryer and bake at 50°C for 5 hours. The average cost moisture of sweet potato leaves obtained is 7.44%. The rehydrated potato leaves are bright in color, the product has no browning, the fermentat...

Embodiment 2

[0016] Embodiment 2, the steps are the same as 1, the difference is that the inoculation amount of Lactobacillus plantarum is 1%, 3%, 5%, 7%, 10% respectively. According to comprehensive evaluation, when the inoculum amount is small, the fermentation time is long. The product productivity is low; when the inoculum is too large, the lactic acid bacteria grow too fast, and the lactic acid and other secondary metabolic wastes increase during the metabolic process. Among them, when the inoculation amount is 5%, the quality is the best.

Embodiment 3

[0017] Embodiment 3, the steps are the same as 1, the difference is that the fermentation temperatures are respectively 26, 28, 30, 32, 34, 36°C. According to comprehensive evaluation, when the fermentation temperature is too low, the growth rate of Lactobacillus plantarum is too slow, and the production efficiency is low. Inhibition, the color of the fermented potato leaves is dull and the browning is serious. Wherein, when the fermentation temperature is 30°C, the flavor of potato leaves is better without browning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com