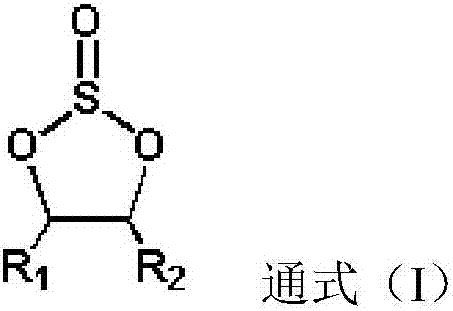

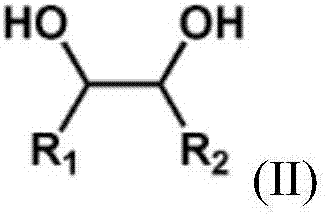

Synthetic method for ethylene sulfite derivative

A vinyl sulfite and synthesis method technology, applied in the direction of organic chemistry, can solve the problems of many by-products, low yield, poor safety, etc., achieve high conversion rate of raw materials, high product yield, and increase reaction conversion rate and the effect of the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

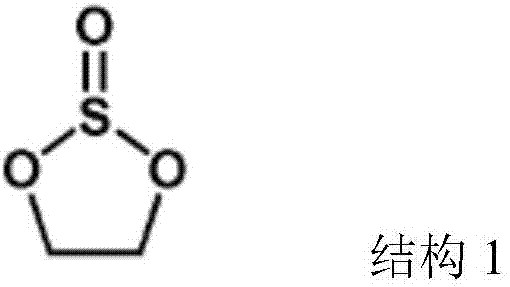

[0023] The synthesis of embodiment 1 vinyl sulfite

[0024] In a three-neck flask equipped with a condenser, a stirrer and a thermometer, add 1000 g of ethylene glycol and 10 g of calcium oxide, and react at 110° C. for 2 hours. In order to prevent water vapor in the air from entering, a drying tube is added to the top of the condensation tube, and anhydrous magnesium sulfate is added into the drying tube. Then vacuum rapid filtration, the water content is 100ppm with trace moisture analyzer.

[0025] In a three-necked flask equipped with a stirrer, a thermometer, and a fractionating tower, add 620 g of dried ethylene glycol, add 8.6 g of tetraisopropyl titanate, react at 120 ° C for 1 hour, and then add 1100 g of dimethyl sulfite , start the reaction when the oil bath is 120°C, and keep the fractionation tower top temperature at 64-67°C by controlling the oil bath temperature not to exceed 150°C. When the temperature of the oil bath was at 150° C. and methanol was no longer...

Embodiment 2

[0028] Example 2 Synthesis of 4,5-dimethyl vinyl sulfite

[0029] Add 900g of 2,3-butanediol and 13g of anhydrous magnesium sulfate into a three-neck flask equipped with a condenser, a stirrer and a thermometer, and react at 120°C for 2 hours. In order to prevent water vapor in the air from entering, a drying tube is added to the top of the condensation tube, and anhydrous magnesium sulfate is added into the drying tube. Vacuum fast filtration then, measure water content with trace moisture meter and be 150ppm.

[0030] In a three-neck flask equipped with a stirrer, a thermometer, and a fractionating tower, add 472 g of dried 2,3-butanediol, add 10 g of n-propyl titanate, react at 120 ° C for 1.5 hours, and then add 550 g of disulfite Methyl esters start to react when the oil bath is 120°C, and by controlling the temperature of the oil bath not to exceed 150°C, the temperature at the top of the fractionation column is kept at 64-67°C. When the temperature of the oil bath was...

Embodiment 3

[0033] Example 3 4-butyl vinyl sulfite

[0034] Add 1000g of 1,2-hexanediol and 15g of anhydrous sodium sulfate into a three-necked flask equipped with a condenser, stirring and thermometer, and react at 130°C for 2 hours. In order to prevent water vapor in the air from entering, a drying tube is added to the top of the condensation tube, and anhydrous magnesium sulfate is added into the drying tube. Vacuum fast filtration then, measure water content with trace moisture meter and be 180ppm.

[0035] In a three-necked flask equipped with a stirrer, a thermometer, and a fractionating tower, add 594 g of dried 1,2-hexanediol, add 11 g of tetrabutyl titanate, react at 120 ° C for 2 hours, and then add 550 g of disulfite Methyl esters start to react when the oil bath is 120°C, and by controlling the temperature of the oil bath not to exceed 150°C, the temperature at the top of the fractionation column is kept at 64-67°C. When the temperature of the oil bath was at 150° C. and met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com