Slump retaining type high-performance solid polycarboxylic acid water reducing agent as well as preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of slump-preserving high-performance solid polycarboxylate water reducing agent and its preparation, and can solve the problems of increasing the preparation cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

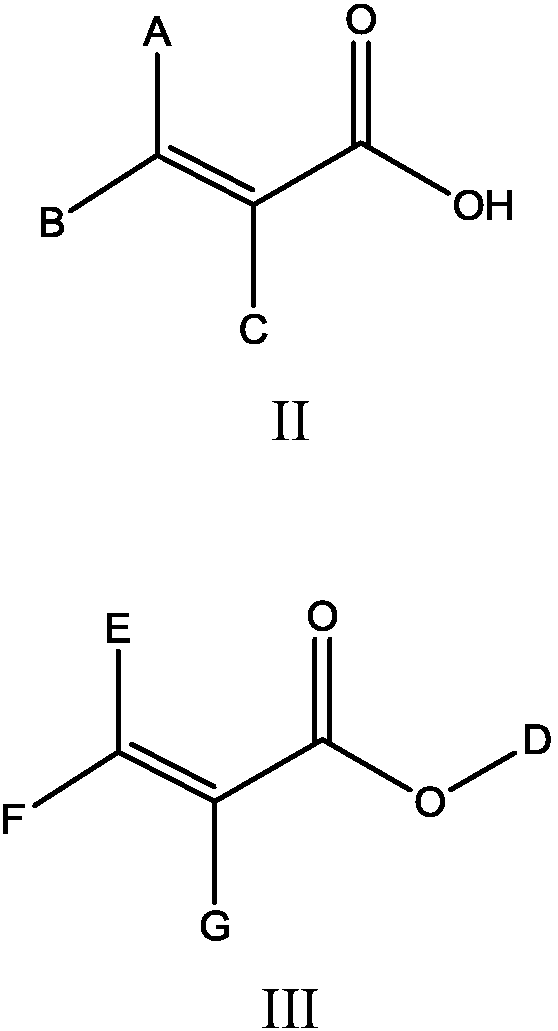

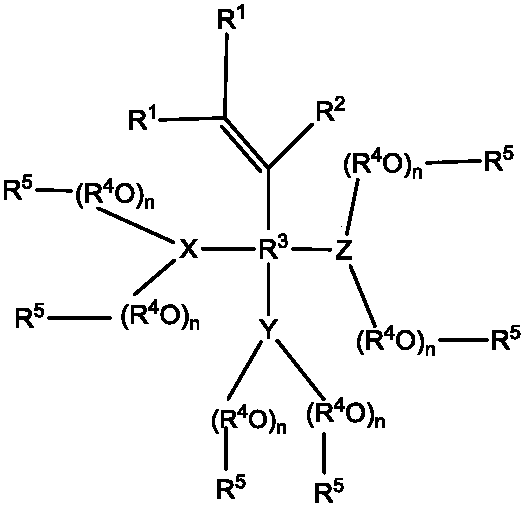

Method used

Image

Examples

preparation example 1

[0073] With reference to the method described in Example 3 and Example 4 in patent document CN201510041919.X, with 2-methallyl alcohol or 3-methyl-3-butene-1-alcohol as initiator, the mass ratio of propylene oxide (PO): ethylene oxide (EO) = 21.5:100, and a liquid unsaturated polyether macromonomer with a molecular weight of 2400 was prepared.

Embodiment 1

[0075] In a 500ml three-necked flask equipped with a stirrer, a thermometer, and a condenser, drop into 258g preparation example 1 with 3-methyl-3-butene-1-alcohol as the liquid unsaturated polyether prepared by the initiator Monomer, 1.8g mercaptoacetic acid, 1.8g L-ascorbic acid, after stirring evenly, start to drop the mixed solution of 27g acrylic acid, 15g hydroxypropyl acrylate, 3.3g tert-butyl peroxybenzoate, the dropping time is 2h, drop After completion, ripen for 1 hour, cool down to room temperature and grind into solid particles. The product is characterized by infrared spectroscopy, and in the infrared spectrum, 3440.75cm-1 is the stretching vibration of O-H; 2871.42cm -1 and 2873.50cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1731.25cm -1 and 1705.85cm -1 It is the stretching vibration of C=O, 1105.68cm -1 and 1259.78cm -1 The very strong absorption peak at is -C-O-C-stretching vibration; the infrared...

Embodiment 2

[0077] In a 500ml three-necked flask equipped with a stirrer, a thermometer, and a condenser, drop into 285g preparation example 1 with 3-methyl-3-butene-1-ol as the liquid unsaturated polyether prepared by the initiator Monomer, 0.3g mercaptoacetic acid, 1.5g L-ascorbic acid, after stirring evenly, start to add dropwise a mixture of 9g acrylic acid, 6g hydroxypropyl acrylate, and 1.5g tert-butyl peroxybenzoate for 2 hours. After completion, ripen for 1 hour, cool down to room temperature and grind into solid particles. The product is characterized by infrared spectroscopy, 3440.25cm-1 in the infrared spectrum is the stretching vibration of O-H; 2871.20cm -1 and 2873.34cm -1 The strong absorption peak is -CH 2 The stretching vibration of - and -CH 3 Bending vibration; 1731.15cm -1 and 1705.60cm -1 It is the stretching vibration of C=O, 1105.45cm -1 and 1259.68cm -1 The very strong absorption peak at is -C-O-C-stretching vibration; the infrared results show that the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com