a flower cluster lafe x eu 1-x o 3 /tio 2 Preparation method of composite superfine red ceramic pigment

A ceramic pigment and composite technology, applied in fibrous fillers, inorganic pigment treatment, chemical instruments and methods, etc., can solve problems such as energy saving and emission reduction, high calcination temperature, long grinding time, etc., and achieve bright colors and raw materials. The effect of easy availability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 2

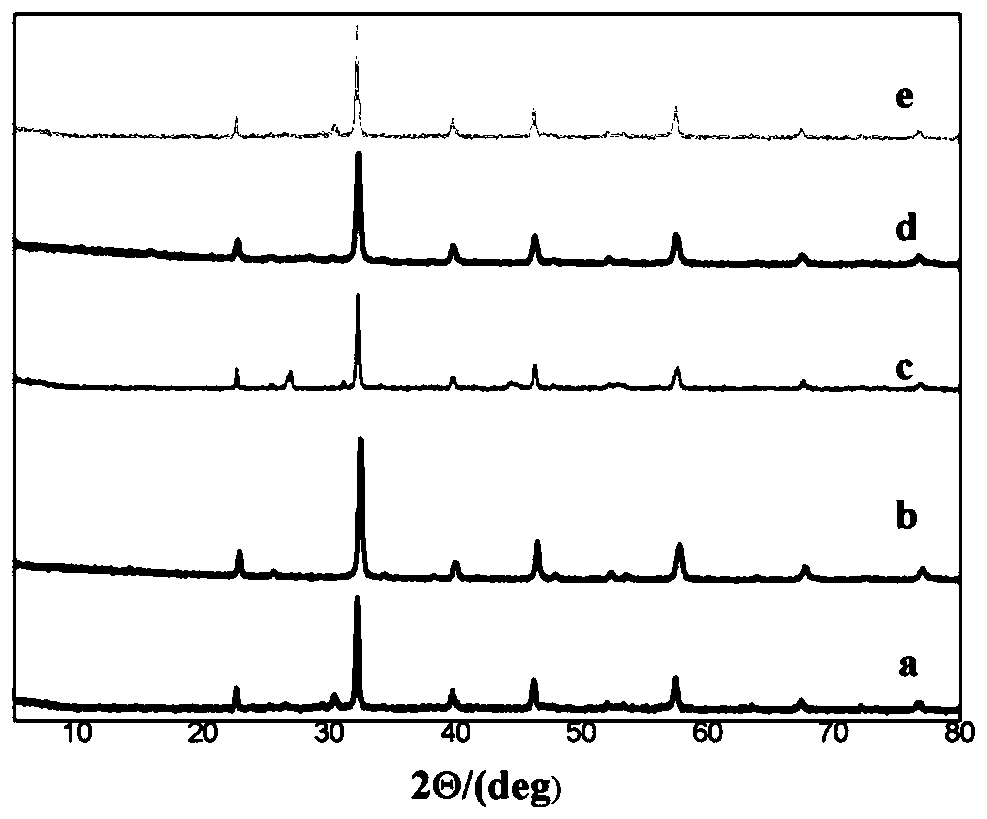

[0031] LaFe x Eu 1-x o 3 Preparation Example 2 (x=0.95, 850°C)

[0032] First, weigh 9g of glycine with a ten-thousandth balance and dissolve it in 180ml of deionized water, stir on a magnetic stirrer at a temperature of 60°C, and then add La(NO 3 ) 3 ·6H 2 O 8.66g, Fe(NO 3 ) 3 .9H 2 O 7.68g, Eu(NO 3 ) 3 .6H 2 O 0.45g, stirred for 110 minutes, then heated on the universal electric furnace, along with the growth of heating time, the liquid expanded rapidly, and released gas, generated fluffy powder, that is, the precursor, and then the prepared precursor was calcined, and the calcined temperature was 850°C, calcination time is 4h, and ground to get the matrix LaFe x Eu 1-x o 3 Pigment powder.

[0033] LaFe x Eu 1-x o 3 Preparation Example 3 (x=0.80, 900°C)

[0034] First, weigh 9g of glycine with a ten-thousandth balance and dissolve it in 200ml of deionized water, stir on a magnetic stirrer at a temperature of 70°C, and then add La(NO 3 ) 3 ·6H 2 O 8.66g, ...

preparation example 5

[0037] LaFe x Eu 1-x o 3 Preparation Example 5 (x=0.85, 750°C)

[0038] First pour 180ml of deionized water into the beaker, set the temperature on a magnetic stirrer at 60°C and stir, add 9g of glycine, then add 8.66g of La(NO 3 ) 3 ·6H 2 O, 6.87g of Fe(NO 3 ) 3 .9H 2 O, 1.34g of Eu(NO 3 ) 3 .6H 2 0, stirred for 110 minutes, then put into a universal electric furnace for heating, and self-propagating combustion occurred when the liquid evaporated quickly, and rapidly expanded to generate fluffy red powder. Then calcined at 750°C for 4 hours, and ground to obtain the matrix.

[0039] LaFe x Eu 1-x o 3 Preparation Example 6 (x=0.85, 700°C)

[0040] First pour 200ml of deionized water into the beaker, set the temperature on a magnetic stirrer at 60°C and stir, add 9g of glycine, then add 8.66g of La(NO 3 ) 3 ·6H 2 O, 6.87g of Fe(NO 3 ) 3 .9H 2 O, 1.34g of Eu(NO 3 ) 3 .6H 2 0, stirred for 110 minutes, then put into a universal electric furnace for heating,...

Embodiment 1

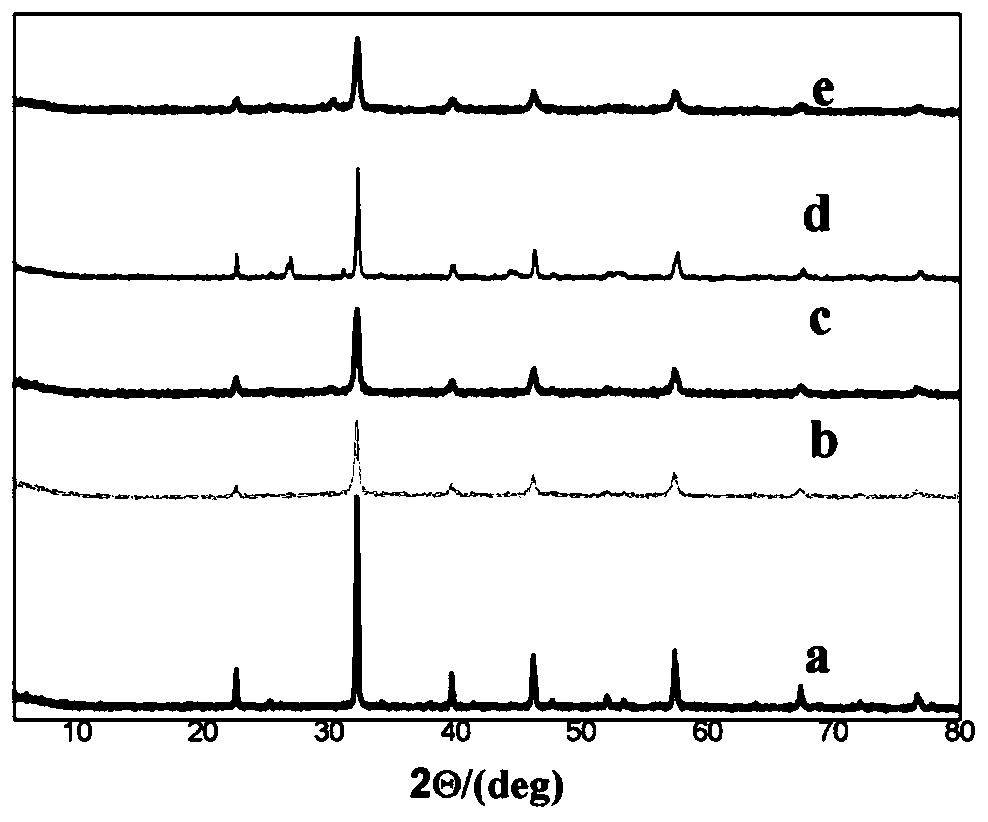

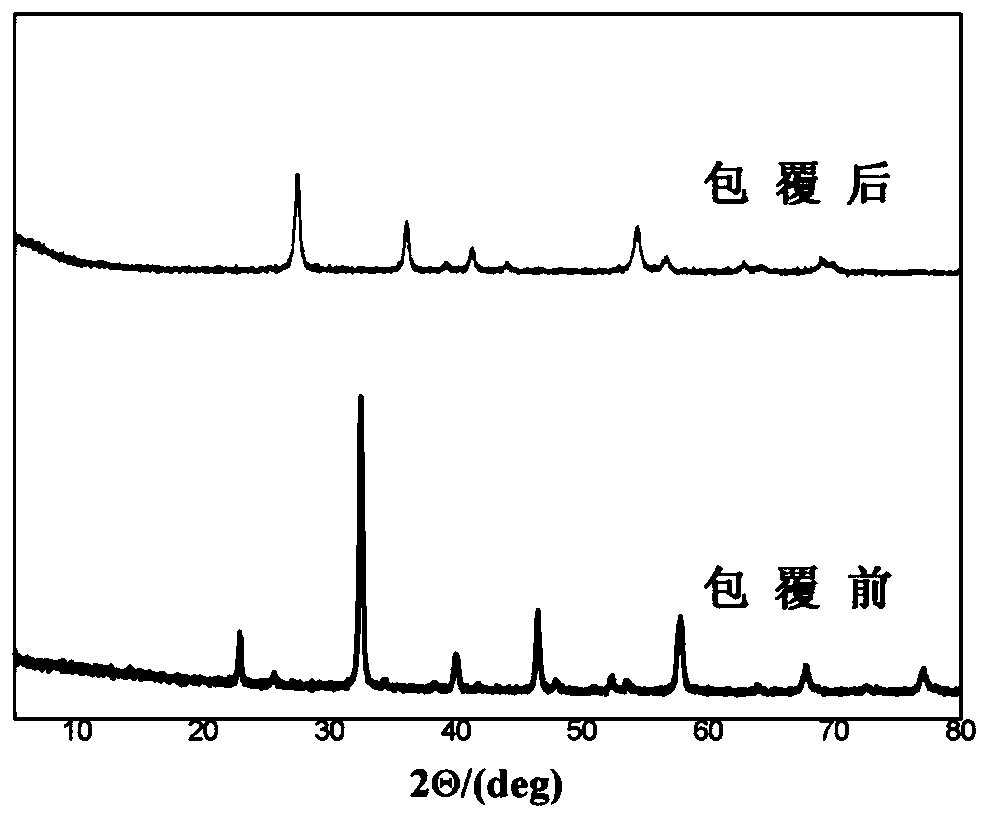

[0043] A flower cluster LaFe x Eu 1-x o 3 / TiO 2 The preparation method of composite superfine red ceramic pigment comprises the steps:

[0044] 1) Add 2.0g of P 123 Join in the hydrochloric acid solution of 1.6mol / L, the volume of HCl in the described hydrochloric acid solution is 133.7ml, and the volume of water is 866.3ml; The temperature of hydrochloric acid solution is 40 ℃;

[0045] 2) Stir for 2 min with a glass rod, wait until P 123 After it is completely compatible with the hydrochloric acid solution, add 4.858g of matrix LaFeO 3 The pigment powder and 4ml of butyl titanate were stirred on a magnetic stirrer for 4 hours, and the stirring temperature on the magnetic stirrer was 40°C to obtain a yellow transparent solution; if the stirring reaction time was less than 4 hours, the product could not fully react for coating, resulting in The product phase is not uniform;

[0046] 3) Cover the obtained solution with plastic wrap and let it stand for 1d, and centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com