A kind of hydrocracking method of blending coal tar

A hydrocracking and coal tar technology, applied in the field of hydrocracking of coal tar blending, can solve the problems of low quality diesel and tail oil, limited naphtha yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

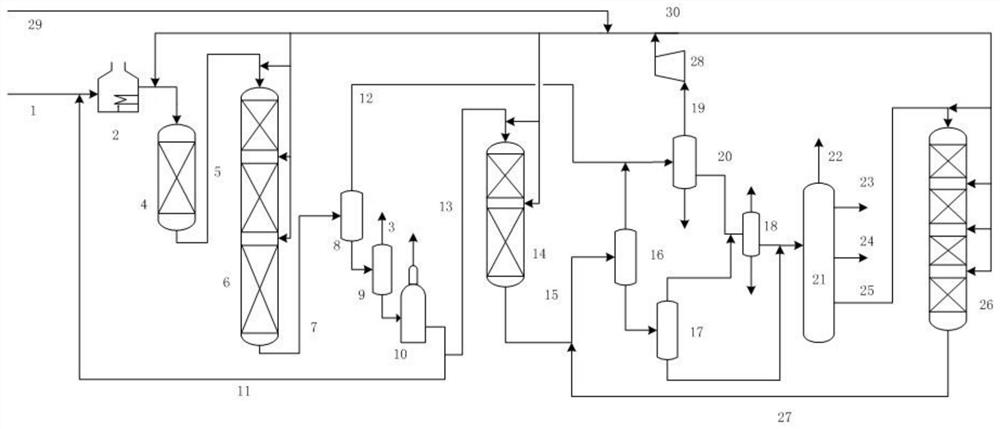

Method used

Image

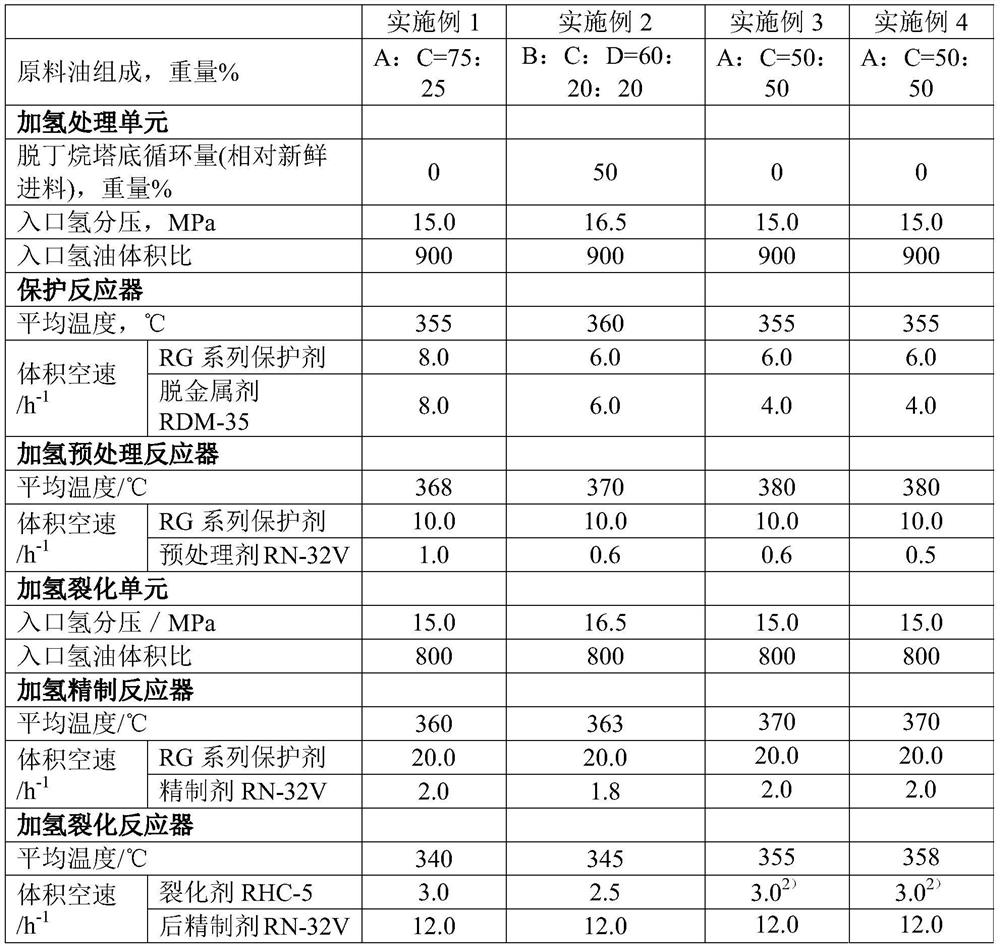

Examples

preparation example Construction

[0047] According to a preferred specific implementation, in the hydrocracking catalyst, the preparation method of the carrier includes the following steps:

[0048] (1) Beta type molecular sieve is mixed with weakly acidic silica-alumina, pseudo-boehmite, peptizer, lubricant and water to obtain a mixture, and the consumption of each component makes the amount of substance of peptizer in the mixture and The total weight ratio of powder is 0.28×10 -4 ~4.8×10 -4 mol / g, the ratio of the weight of water to the amount of peptizer is 2.0×10 3 ~30×10 3 g / mol, the total weight of the powder is the sum of the weight of the Beta type molecular sieve, pseudo-boehmite and weakly acidic silica-alumina, and the amount of the peptizer substance refers to the metered H proton mole in the peptizer number; the lubricant is squash powder and / or graphite, based on the total weight of the powder, the ratio of the lubricant to the total weight of the powder is: (1~9):100;

[0049] (2) kneading, ...

preparation example 1

[0086] Preparation Example 1: Preparation of Hierarchical Porous Hydrocracking Catalyst C-1 Containing Silicon and Aluminum

[0087] 236.5 grams of pseudo-boehmite PB1 (dry basis 0.74) and 122 grams of molecular sieve Beta (produced by Sinopec Catalyst Jianchang Branch, silicon-aluminum ratio 27, pore volume 0.395mL / g, dry basis 0.82), 16 grams of scallop powder , 78.9 grams of weakly acidic silicon-alumina (produced by German Condea company, trade name Sira-40, pore volume 0.88mL / g, specific surface 468m 2 / g, silicon dioxide weight content 40%, infrared B acid acidity value 0.04mmol / g, dry basis 0.76), 7.7mL concentrated nitric acid with a purity of 65%, and 310mL deionized water are mixed evenly, and extruded into a circumscribed circle with a diameter of 1.6 The trefoil strips of 1.2 mm were dried at 120° C. for 3 hours, and then calcined at 600° C. for 3 hours to obtain a carrier. The composition is shown in Table 2.

[0088] After cooling to 25°C, get 100 grams of carri...

preparation example 2

[0090] Preparation Example 2: Preparation of Silicon-Al-Containing Hierarchical Hydrocracking Catalyst C-2

[0091] With 233.3 grams of pseudo-boehmite SB (dry basis 0.75, the dry basis measurement method is to put a certain amount of original powder into a crucible with a cover and put it in a muffle furnace, heat up to 700 ° C and keep the temperature for 1 hour, and calculate the remainder with the original Powder ratio, the same below) and 122 grams of molecular sieve Beta (produced by Sinopec Catalyst Jianchang Branch, silicon-aluminum ratio 27, pore volume 0.395mL / g, dry basis 0.82), 78.9 grams of weakly acidic silicon-aluminum (produced by German Condea company, Product name Sira-40, pore volume 0.88ml / g, specific surface area 468m 2 / g, silica weight content 40%, infrared B acid acidity value 0.04mmol / g, dry basis 0.76), 11 grams, 13.7mL purity are the concentrated nitric acid of 65% (molar concentration is 14.4mol / L, The same below), 226.8mL of deionized water were m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com