A kind of organic-inorganic hybrid solar cell and preparation method thereof

A solar cell and inorganic technology, applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency, loss, and low electron mobility of organic photovoltaic cells, and achieve the effects of improving photoelectric conversion efficiency, improving work function, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

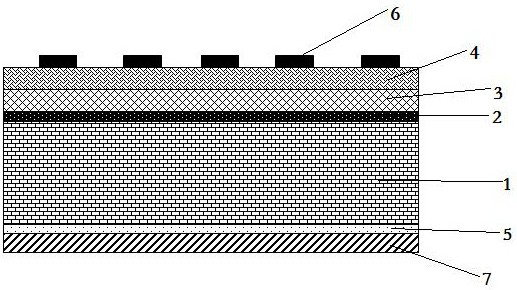

[0019] A method for preparing an organic-inorganic hybrid solar cell proposed in a specific embodiment of the present invention comprises the following steps: (1) cleaning of the silicon substrate: ultrasonically cleaning the n-type silicon chip in acetone, ethanol, and deionized water for 10-30 Minutes, and blow dry with nitrogen, then place the dried n-type silicon wafer in concentrated sulfuric acid / hydrogen peroxide mixed solution, heat treatment at 100-120°C for 40-60 minutes, then rinse the n-type silicon wafer with deionized water, and finally use Hydrofluoric acid removes the natural silicon oxide layer on the surface of the n-type silicon wafer; (2) surface passivation treatment of the silicon substrate: the n-type silicon wafer obtained in step 1 is blown dry with nitrogen, and then immersed in saturated phosphorus pentachloride In the chlorobenzene solution, heat treatment at 110°C for 40-60 minutes, then take the n-type silicon chip out of the saturated phosphorus p...

Embodiment 1

[0023] A preparation method of an organic-inorganic hybrid solar cell, comprising the following steps: (1) cleaning of a silicon substrate: ultrasonically cleaning an n-type silicon chip in acetone, ethanol, and deionized water for 25 minutes in sequence, and blowing dry with nitrogen, and then The dried n-type silicon wafer is placed in a mixed solution of concentrated sulfuric acid / hydrogen peroxide, heat-treated at 110°C for 50 minutes, then rinsed with deionized water, and finally removes the surface of the n-type silicon wafer with hydrofluoric acid. Natural silicon oxide layer; (2) surface passivation treatment of silicon substrate: the n-type silicon chip obtained in step 1 is blown dry with nitrogen, then immersed in a chlorobenzene solution of saturated phosphorus pentachloride, and heat-treated at 110° C. for 50 minutes, Next, the n-type silicon chip is taken out from the chlorobenzene solution of saturated phosphorus pentachloride and cleaned in chlorobenzene and tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com