Preparation method of lactic acid bacterium microcapsule

A technology of lactic acid bacteria microcapsules and lactic acid bacteria, which is applied in the field of food biology, can solve the problems such as the decrease of viable bacteria count, and achieve the effects of easy operation, high embedding rate and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

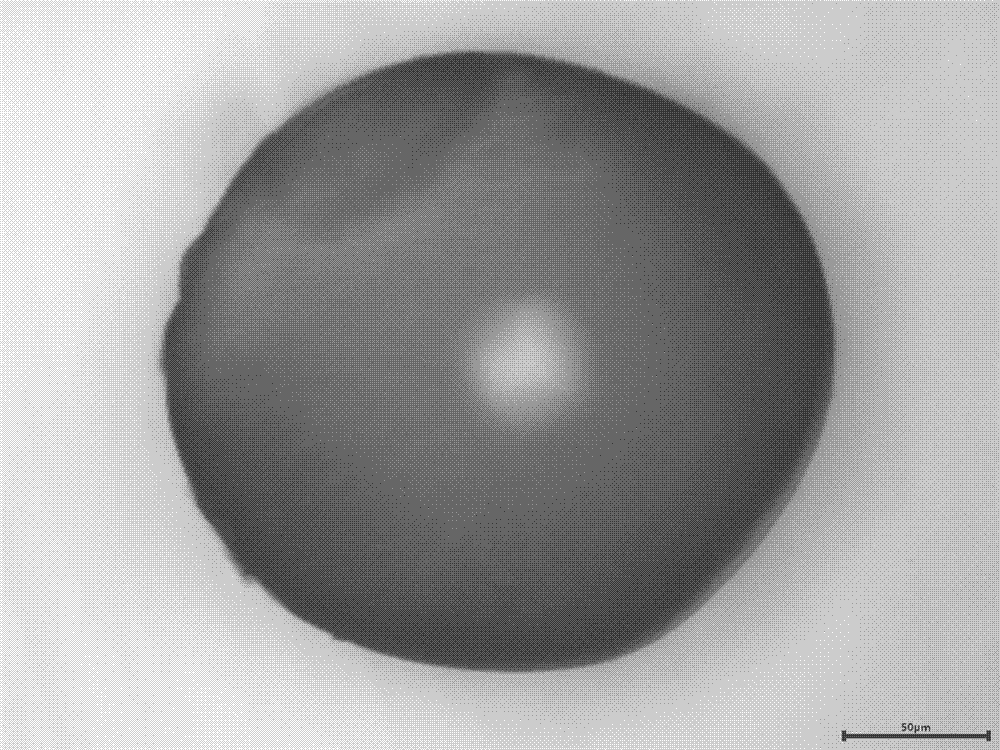

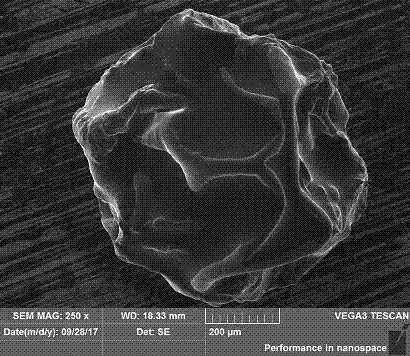

Image

Examples

Embodiment 1

[0028] A preparation method for lactic acid bacteria microcapsules, comprising the following steps:

[0029] 1. Strain activation

[0030] Lactobacillus bulgaricus preserved in a glycerol storage tube stored at -80°C was inoculated into liquid MRS medium for activation, cultured at 40°C for 16 hours to the end of logarithmic growth, activated for three generations, and the third generation fermentation broth was collected. Centrifuge the fermentation broth at 6000rpm / min for 6min to collect the bacteria sludge, then resuspend it with 0.9% sterile saline to obtain a concentrated bacteria solution, then use agar medium to pour culture at a temperature of 37°C, and count The living bacteria density of the obtained culture solution was 6.6×10 9 cfu / mL. Finally, 0.6% fructo-oligosaccharides were added to the obtained fermentation broth to form a synbiotic solution.

[0031] 2. Preparation of bacterial gel mixture

[0032] Sodium alginate and pectin were dissolved in distilled w...

Embodiment 2

[0037] A preparation method for lactic acid bacteria microcapsules, comprising the following steps:

[0038] 1. Strain activation

[0039] Inoculate Lactobacillus bulgaricus and Lactobacillus rhamnosus stored in glycerol storage tubes at -80°C in a ratio of 1:1 in liquid MRS medium for activation, culture at 40°C for 16 hours to the end of logarithmic growth, and activate For three generations, the third generation fermentation broth was collected. Centrifuge the fermentation broth at 6000rpm / min for 6min to collect the bacteria sludge, then resuspend it with 0.9% sterile saline to obtain a concentrated bacteria solution, then use agar medium to pour culture at a temperature of 37°C, and count The living bacteria density of the culture solution obtained was 7.2×10 9 cfu / mL. Finally, 0.6% fructo-oligosaccharide and 1.25% isomalto-oligosaccharide were added to the obtained fermentation broth to form a synbiotic solution.

[0040] 2. Preparation of bacterial gel mixture

[0...

Embodiment 3

[0046] A preparation method for lactic acid bacteria microcapsules, comprising the following steps:

[0047] 1. Strain activation

[0048] Inoculate Lactobacillus casei and Lactobacillus rhamnosus stored in glycerol storage tubes stored at -80°C in a ratio of 1:1 in liquid MRS medium for activation, culture at 40°C for 16 hours to the end of logarithmic growth, and activate For three generations, the third generation fermentation broth was collected. Centrifuge the fermentation broth at 5000rpm / min for 8min to collect the bacteria sludge, then resuspend it with 0.9% sterile saline to obtain a concentrated bacteria solution, then use agar medium to pour culture at a temperature of 37°C, count The live bacteria density of the culture solution obtained was 7.5×10 9 cfu / mL. Finally, 1% inulin and 1.25% isomaltose oligosaccharides were added to the obtained fermentation liquid to form a synbiotic solution.

[0049] 2. Preparation of bacterial gel mixture

[0050] Sodium algina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com