Flame-retardant room-temperature vulcanized silicon rubber and preparation method thereof

A technology of room temperature vulcanization and silicone rubber, which is applied in the field of rubber, can solve the problems of human body, environmental hazards, large dosage, and reduce the mechanical properties of silicone rubber, etc., and achieve the advantages of simple and easy preparation method, wide source of raw materials, and good flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

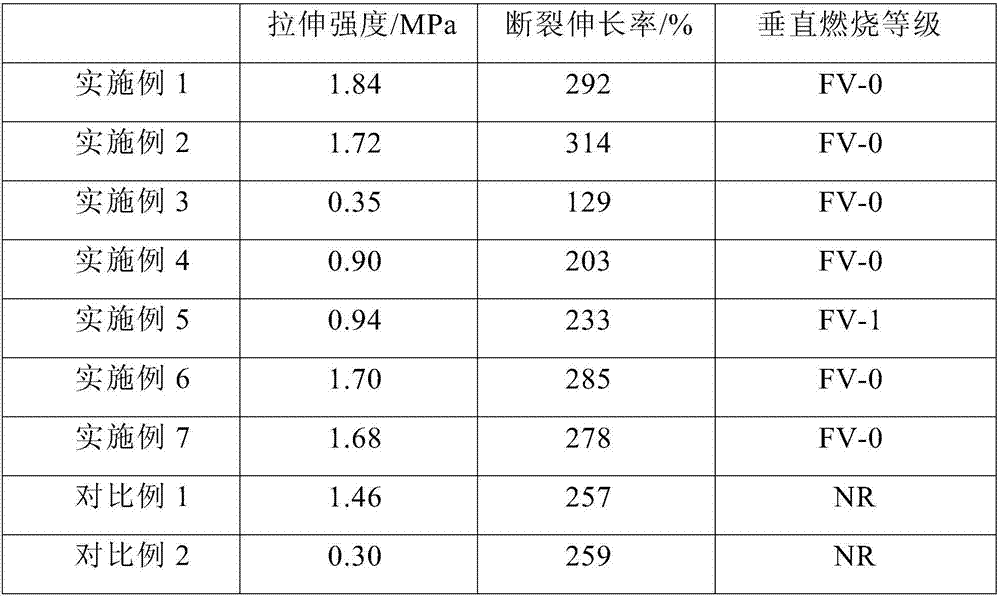

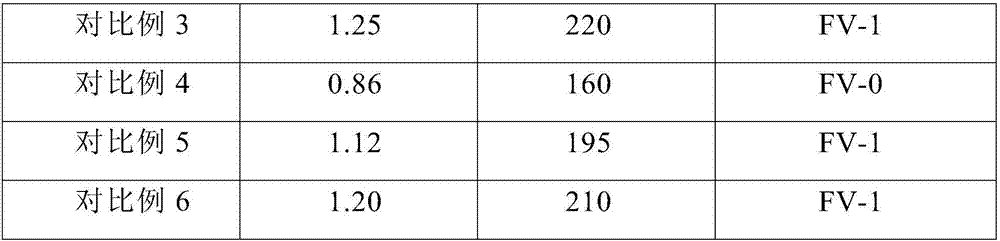

Examples

preparation example Construction

[0029] According to the preparation method of the flame-retardant RTV silicone rubber according to the second aspect of the present application, for preparing the flame-retardant RTV silicone rubber described in the first aspect of the present application, the method comprises the steps of: S1: The base siloxane, the reinforcing filler and the dimethyl silicone oil are fully mixed and stirred evenly, then the flame retardant is added and the stirring is continued, then the crosslinking agent and the catalyst are added, and the mixed material is obtained after thorough stirring and mixing; S2, the above mixed material is obtained. Pour it into a mold, vacuumize to remove air bubbles, and then perform a room temperature curing reaction. After the reaction, a flame retardant room temperature vulcanized silicone rubber is obtained.

[0030] In the preparation method of the flame-retardant RTV silicone rubber according to the second aspect of the present application, the curing time...

Embodiment 1

[0033] 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mPa·s, 5 parts of a specific surface area of 200m 2 / g of hydrophobic fumed silica and 5 parts of dimethyl silicone oil with a viscosity of 500 mPa·s are fully stirred and mixed evenly, then 60 parts of lipophilic magnesium hydroxide and 15 parts of melamine are added in batches, fully stirred and mixed evenly, wherein, The lipophilic magnesium hydroxide is modified by using sodium stearate surfactant, and the mass of sodium stearate is 5% of the mass of magnesium hydroxide; then 2 parts of ethyl orthosilicate and 1.2 parts of dilauric acid are added Dibutyltin, stir and mix well, pour it into a Teflon mold, vacuumize to remove air bubbles, and then flatten it. After curing at room temperature for 24 hours, a flame retardant room temperature vulcanized silicone rubber is obtained.

Embodiment 2

[0035] The preparation method of the flame-retardant RTV silicone rubber is the same as that in Example 1, except that,

[0036] The number of additions of melamine is 20 parts, and the number of additions of dimethicone is 7 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com