High florine water treatment equipment

A high-efficiency, aqueous solution technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of avoiding disinfection by-products, reducing treatment costs and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

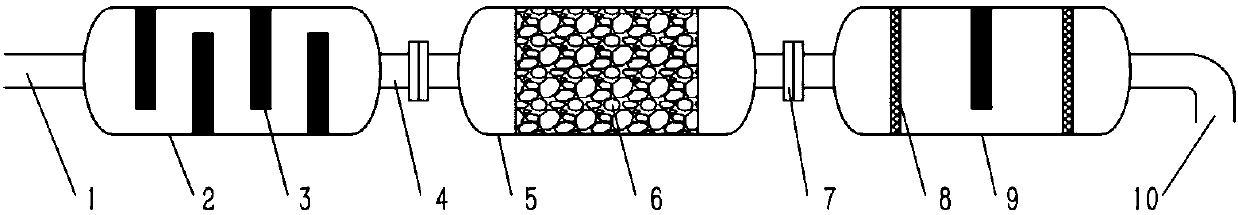

Image

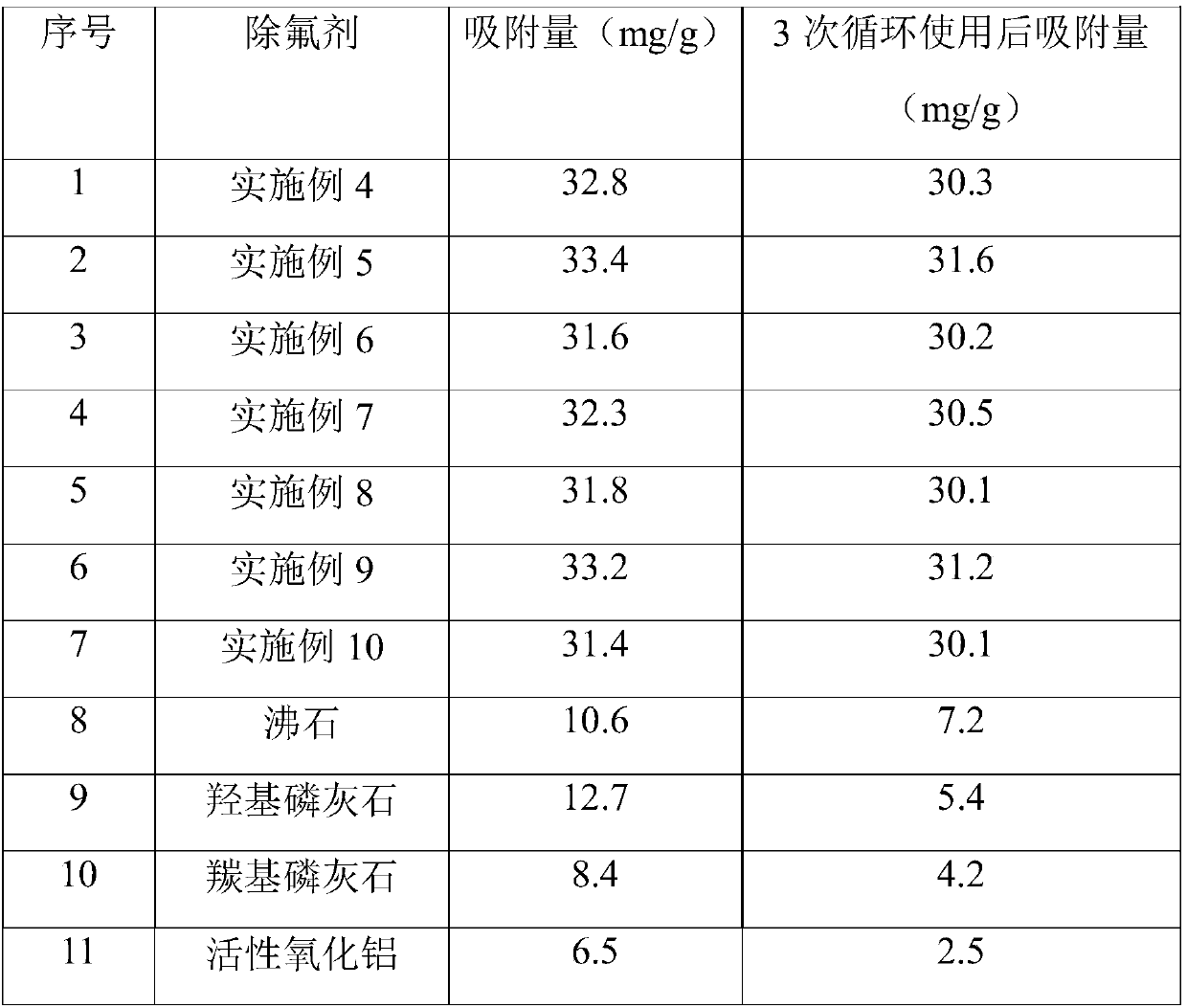

Examples

Embodiment 1

[0063] Step (1): FeCl 2 、NiCl 2 , Mn(OAc) 2 Mix according to the molar ratio of 1:2:1, then add 20mL of water and stir until dissolved;

[0064] Step (2): Add 1g of EDTA to the above reaction solution, then add NaOH to adjust the pH to 8; after fully stirring and mixing, transfer the mixture to a 25mL hydrothermal reaction kettle for hydrothermal reaction, wherein the reaction temperature is 180 °C, the reaction time is 8 hours;

[0065] Step (3): After the reaction is completed, the above-mentioned reaction product is filtered, washed with water, dried, and then transferred to a high-temperature calciner, and treated at 600° C. for 4 hours.

Embodiment 2

[0067] Step (1): FeCl 2 、NiCl 2 , Mn(OAc) 2 Mix according to the molar ratio of 1:1:1, then add 20mL of water and stir until dissolved;

[0068] Step (2): Add 1 g of carboxymethyl cellulose to the above reaction solution, then add NaOH to adjust the pH to 8; after fully stirring and mixing, transfer the mixture to a 25 mL hydrothermal reaction kettle for hydrothermal reaction, wherein The reaction temperature is 180°C, and the reaction time is 8 hours;

[0069] Step (3): After the reaction is completed, the above-mentioned reaction product is filtered, washed with water, dried, and then transferred to a high-temperature calciner, and treated at 800° C. for 4 hours.

Embodiment 3

[0071] Step (1): FeCl 2 、NiCl 2 , Mn(OAc) 2 Mix according to the molar ratio of 1:1:1, then add 20mL of water and stir until dissolved;

[0072] Step (2): Add 1g of chitosan to the above reaction solution, then add NaOH to adjust the pH to 8; after fully stirring and mixing, transfer the mixture to a 25mL hydrothermal reaction kettle for hydrothermal reaction, wherein the reaction temperature is 200°C, and the reaction time is 8 hours;

[0073] Step (3): After the reaction is completed, the above-mentioned reaction product is filtered, washed with water, dried, then transferred to a high-temperature calciner, and treated at 800° C. for 6 hours.

[0074] 2. Preparation of fluorine removal adsorption material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com