Heating control device

A technology of a control device and a control unit, which is applied in the directions of control devices, battery/fuel cell control devices, circuit devices, etc., can solve problems such as power consumption, and achieve the effect of reducing power consumption and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

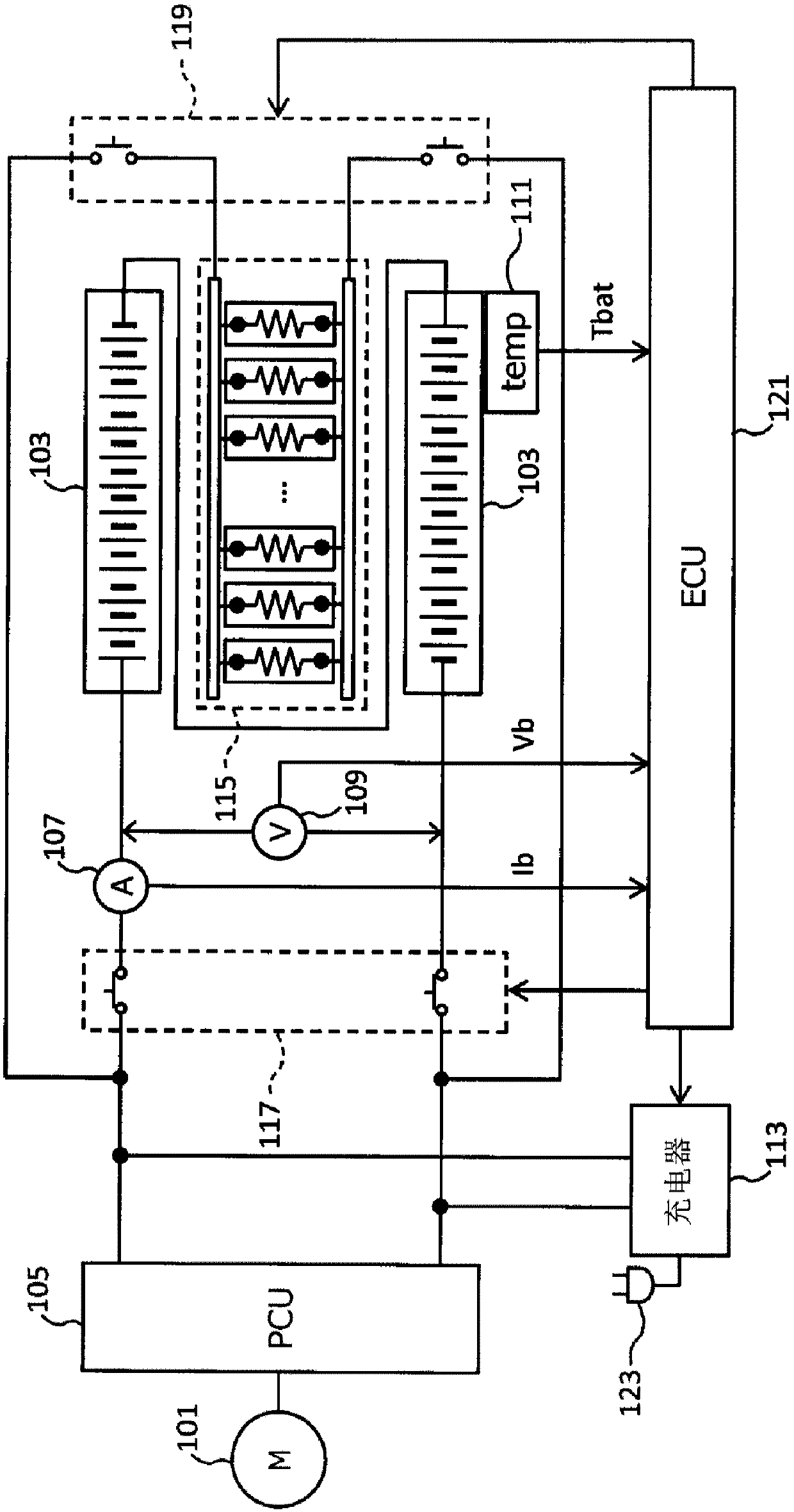

[0049]The heating control device according to the first embodiment is mounted on plug-in electric vehicles such as EV (Electric Vehicle) and HEV (Hybrid Electric Vehicle) installed with an electric motor driven by electric power supplied from a battery as a drive source. vehicle. figure 1 It is a block diagram showing the configuration of the heating control device of the first embodiment. Such as figure 1 As shown, the heating control device of the first embodiment includes a motor 101, a battery 103, a PCU (Power Control Unit: power control unit) 105, a current sensor 107, a voltage sensor 109, a temperature sensor 111, a charger 113, a heater 115, Switching units 117 and 119 and an ECU (Electric Control Unit: Electronic Control Unit) 121 .

[0050] The electric motor 101 is a drive source that generates power for running the electric vehicle.

[0051] The storage battery 103 has a plurality of storage cells such as lithium-ion batteries and nickel-metal hydride batteri...

Embodiment 1

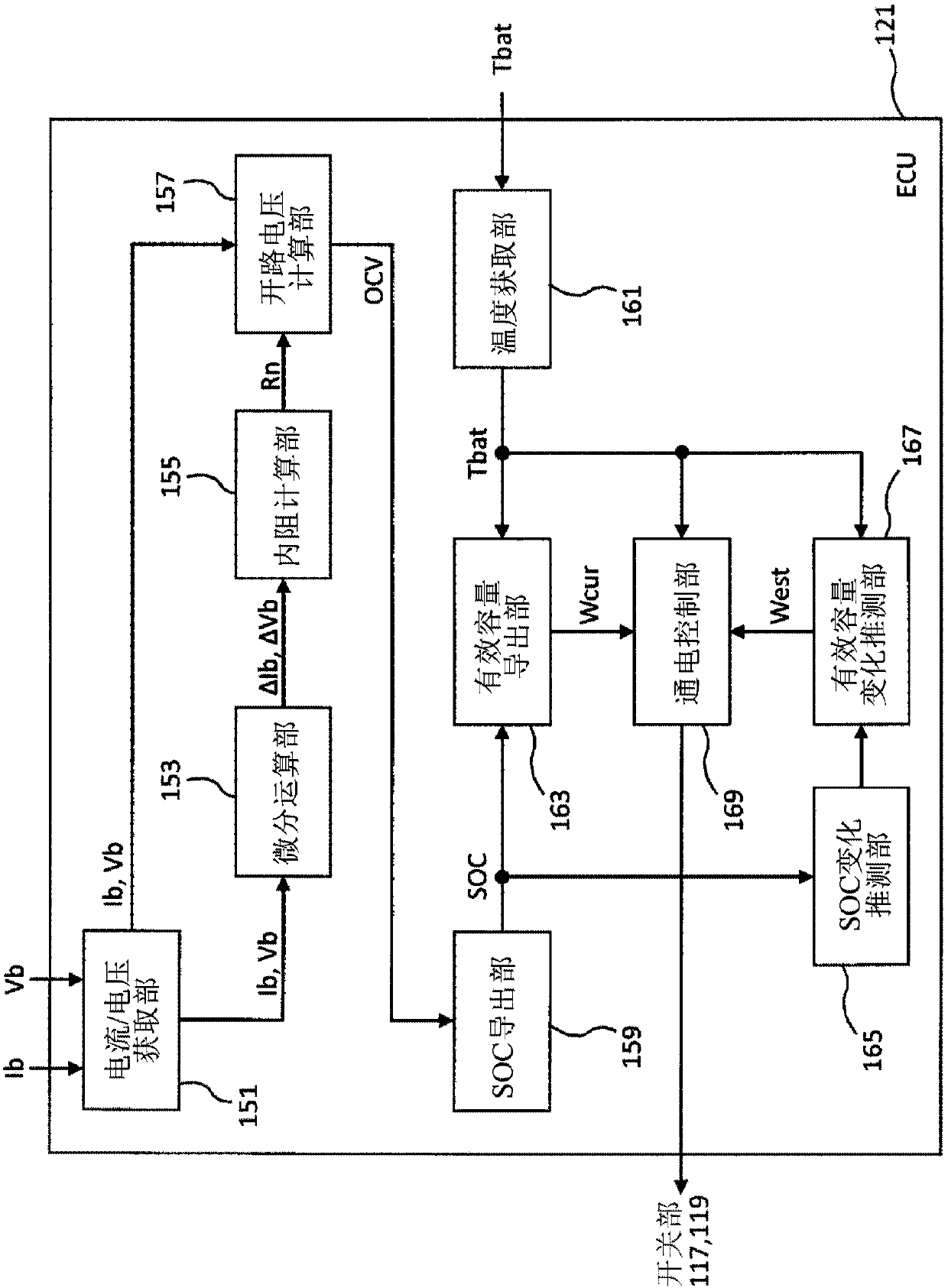

[0059] figure 2 It is a block diagram showing the internal configuration of ECU 121 in Example 1 of the first embodiment. Such as figure 2 As shown, the ECU 121 has a current / voltage acquisition unit 151 , a differential calculation unit 153 , an internal resistance calculation unit 155 , an open circuit voltage calculation unit 157 , an SOC derivation unit 159 , a temperature acquisition unit 161 , an effective capacity derivation unit 163 , and an SOC change estimation unit 165 , The effective capacity change estimation unit 167 and the energization control unit 169 .

[0060] The current / voltage acquisition unit 151 acquires the charging and discharging current Ib detected by the current sensor 107 and the terminal voltage Vb detected by the voltage sensor 109 . The differential calculation unit 153 performs differential calculations on the charge and discharge current Ib and the terminal voltage Vb acquired by the current / voltage acquisition unit 151 . The internal re...

Embodiment 2

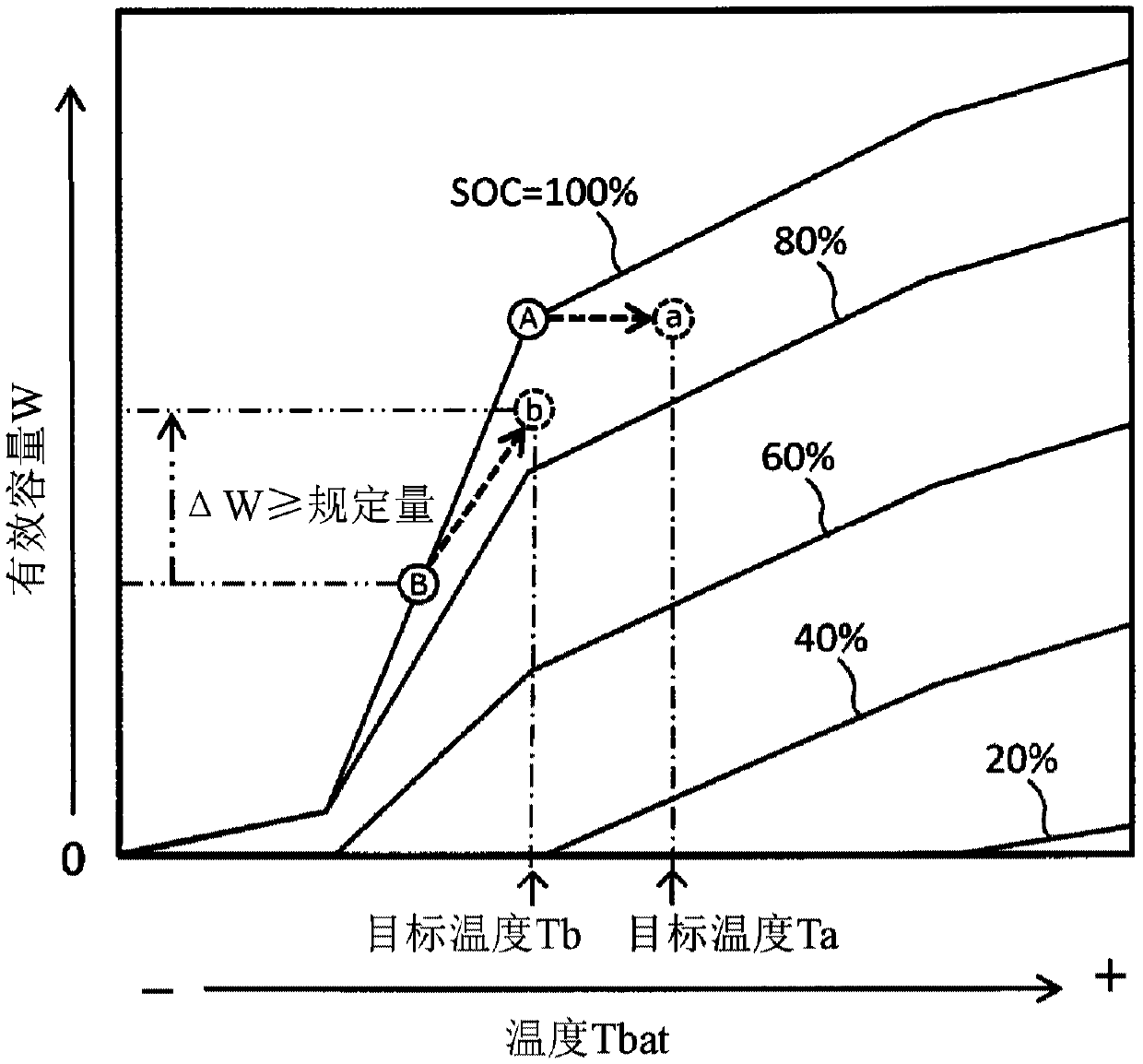

[0071] Figure 4 It is a figure which shows the control related to the heating of the storage battery 103 using the heater 115 in Example 2 of 1st Embodiment. exist Figure 4 In the example shown, it is assumed that after the electric vehicle is driven in a very cold temperature environment, the plug 123 is not connected to the external power supply, and the state in which the electric vehicle is parked in the same temperature environment continues. Even if the temperature Tba of the battery 103 in the electric vehicle just finished running is 0°C, the temperature Tbat of the battery 103 falls because the outside air temperature To is extremely low (eg -40°C) lower than 0°C. However, if the battery 103 drops to the outside air temperature To, the output of the battery 103 will drop significantly and the electric vehicle cannot run. Therefore, it is necessary to keep the battery 103 at an absolute lower limit temperature T1 higher than the outside air temperature To (for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com