Preparation method of nitrogen-doped porous carbon material based on organic covalent framework

A nitrogen-doped porous carbon and covalent technology, which is applied in the field of supercapacitor electrode materials and composite materials, can solve the problem of low specific capacity and achieve the effects of low density, good cycle stability, and good electrical storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

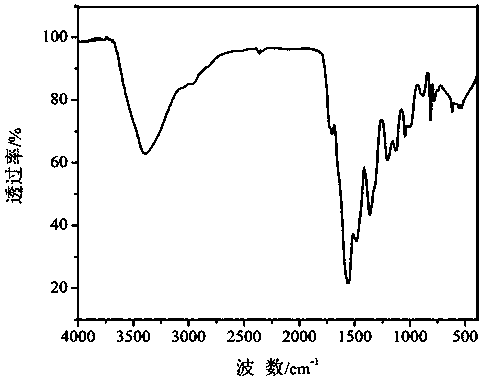

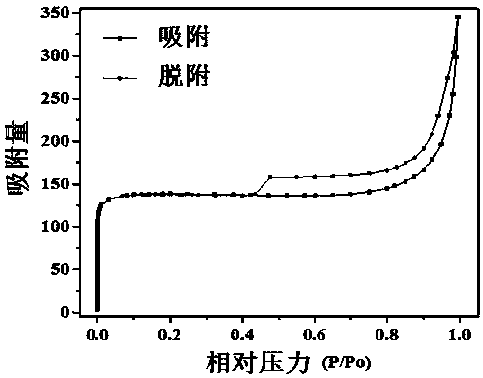

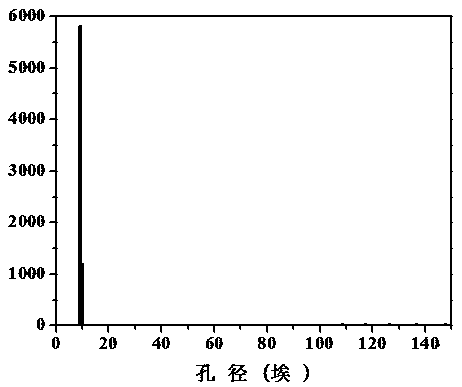

[0035] Dissolve 0.9733g of p-phenylenediamine and 1.107g of cyanuric chloride (the molar ratio of substances is 3:2) in 35ml and 10ml of dioxane-mesitylene-acetic acid mixed solvents respectively (the volume ratio of the three solvents is 5 :5:1), then transfer the mixed solution to a stainless steel autoclave, and keep it at 120°C for 70 hours; the product is washed repeatedly with tetrahydrofuran and methanol, after washing, it is vacuum dried at 120°C for 24 hours, and the obtained Earthy yellow powder precursor. Burn the precursor at 700°C for 3 hours in a nitrogen atmosphere to obtain a black carbon material product with a specific surface area of about 398m 2 g -1 , with a pore size of about 1 nm.

[0036] The calomel electrode was used as the reference electrode, the platinum sheet electrode was used as the auxiliary electrode, the active material was coated on the nickel foam as the working electrode, and 6 M KOH was used as the electrolyte to conduct the electroch...

Embodiment 2

[0038] Dissolve 0.9733g of p-phenylenediamine and 1.107g of cyanuric chloride (the molar ratio of substances is 3:2) in 35 ml and 10ml of dioxane-mesitylene-acetic acid mixed solvents respectively (the volume ratio of the three solvents is 5:5:1), then transfer the mixed solution to a stainless steel autoclave, and keep it at 120°C for 70 hours; the product is washed repeatedly with tetrahydrofuran and methanol, after washing, it is vacuum-dried at 120°C for 24 hours, and ground to obtain The khaki powder precursor. The precursor was burned at 500 °C for 3 hours in a nitrogen atmosphere to obtain a black carbon material product with a specific surface area of about 60 m 2 g -1, the pore size is about 1.4nm. When the current density is 0.5 A g -1 , the specific capacitance is 1155 F·g -1 .

Embodiment example 3

[0040] Dissolve 0.9733g of p-phenylenediamine and 1.107g of cyanuric chloride (the molar ratio of substances is 3:2) in 35 ml and 10ml of dioxane-mesitylene-acetic acid mixed solvents respectively (the volume ratio of the three solvents is 5:5:1), then transfer the mixed solution to a stainless steel autoclave, and keep it at 120°C for 70 hours; the product is washed repeatedly with tetrahydrofuran and methanol, after washing, it is vacuum-dried at 120°C for 24 hours, and ground to obtain The khaki powder precursor. Burn the precursor at 700 °C for 1.5 hours in a nitrogen atmosphere to obtain a black carbon material product with a specific surface area of about 100 m 2 g -1 , with a pore size of about 1.2 nm. When the current density is 0.5 A g -1 , the specific capacitance is 1095 F·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com