UV cured EVA optical film and preparation method thereof

An optical film and photoinitiator technology, applied in the directions of non-polymer organic compound adhesives, non-polymer adhesive additives, adhesive additives, etc. Produce acetic acid and other problems to achieve the effect of reducing blue light damage to eyes, avoiding bubbles, and reducing eye damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

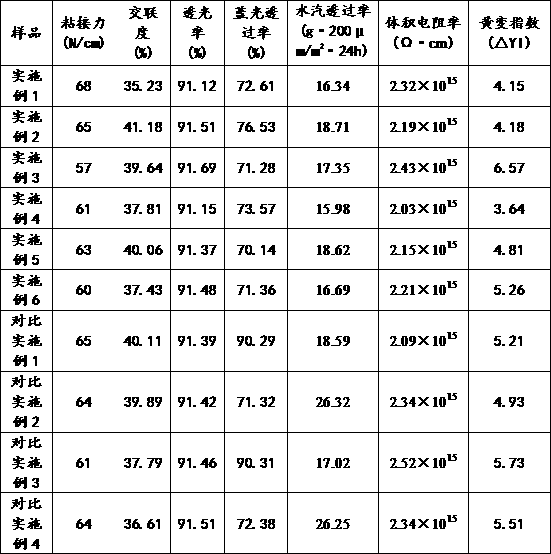

Examples

Embodiment 1

[0026] Add 1.2 parts to 70 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 33% and a melting point of 70°C and 30 parts by weight of an ethylene-methyl methacrylate copolymer with a MMA content of 24% and a melting point of 80°C Photoinitiator 4,4'-bis(diethylamino)benzophenone, 0.5 part of crosslinking agent triallyl cyanurate, 1.0 part of tackifier γ-methacryloxypropyl trimethoxy 2-[[1-[[(2,3-dihydro-2-oxo-1H-benzimidazol-5-yl)amino]carbonyl]-2-oxopropyl Dimethyl ]azo]-1,4-phthalate, 0.6 part light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 0.1 part plasticizer Agent diisooctyl phthalate, 0.4 parts of antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, added to the high-speed mixer for premixed to obtain a premix. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer is obtained through extrusion, upper and ...

Embodiment 2

[0028] Add 2.0 parts by weight to 90 parts by weight of ethylene-vinyl acetate copolymer with a VA content of 33% and a melting point of 70°C and 10 parts by weight of an ethylene-methyl methacrylate copolymer with a MMA content of 24% and a melting point of 80°C Photoinitiator acrylated benzophenone, 0.3 parts of crosslinking agent trimethylolpropane trimethacrylate, 1.2 parts of tackifier vinyltrimethoxysilane, 0.1 part of blue light absorber 2-(2-cyano Base-4-nitrophenylazo)-6-isopropylphenol, 0.4 parts of light stabilizer N,N,-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1 , 6-hexamethylenediamine, 0.9 parts of plasticizer cresyl diphenyl phosphate, 0.3 parts of antioxidant bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, added to the high-speed mixer Premixing is carried out to obtain a premix. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer is obtained through extrusi...

Embodiment 3

[0030]Add 1.5 parts by weight to 80 parts by weight of ethylene-vinyl acetate copolymer with VA content of 33% and melting point of 70°C and 20 parts by weight of ethylene-methyl methacrylate copolymer with MMA content of 24% and melting point of 80°C Photoinitiator 4,4'-bis(diethylamino)benzophenone, 1.0 parts of crosslinking agent ethylene glycol dimethacrylate, 0.3 parts of tackifier γ-glycidyl ether propyl trimethoxysilane, 0.6 part of blue light absorber 2,4-dihydro-5-methyl-2-phenyl-4-phenylazo-3H-pyrazolin-3-one, 0.1 part of light stabilizer bis(2,2, 6,6-tetramethyl-4-piperidinyl) sebacate, 1.1 parts of plasticizer di-isooctyl phthalate, 1.0 parts of antioxidant tetrakis[β-(3,5-di-tert-butyl Base-4-hydroxyphenyl) propionate] pentaerythritol ester, added to a high-speed mixer for pre-mixing to obtain a pre-mixture. The obtained premix is put into the hopper of the single-screw casting machine, melted and plasticized at 100°C, and the film thickness of the middle layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com