A kind of preparation method based on asphaltene highly active trace transition metal catalyst

A technology of transition metals and asphaltene, which is applied in the field of preparation of trace transition metal catalysts to achieve the effects of less metal loading, high catalytic efficiency, and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of trace transition metal catalyst comprises the steps:

[0024] a. Using Soxhlet extraction method to extract asphaltenes, mixing the coal liquefaction residue with an asphaltene extraction solvent, and extracting the asphaltenes in the coal liquefaction residue at 50-90°C;

[0025] b. Place the clean corundum tube in a tube furnace, and raise the temperature of the high temperature part of the corundum tube to the reaction temperature under an atmosphere of argon, nitrogen or ammonia;

[0026] c. Put the corundum boat with asphaltene into the tube furnace, stop heating after 1-2h, and cool the reaction furnace to room temperature under the atmosphere of argon, nitrogen or ammonia;

[0027] d. Put another corundum boat with a transition metal sample into the tube furnace. Under the set conditions: 900-1500 ° C, normal pressure and argon, nitrogen or ammonia atmosphere or vacuum state, vacuum The degree of vacuum is 0-0.1; after heating for 1-6 h...

Embodiment 1

[0033] Embodiment 1: Put the corundum tube into a tube furnace, and under the protection of an argon inert gas with a flow rate of 0.05L / min, the temperature of the high temperature part of the corundum tube is raised to 900°C;

[0034] Put the corundum boat with asphaltene into the reaction furnace, stop heating after 1h, and cool the reaction furnace to room temperature under an ammonia atmosphere;

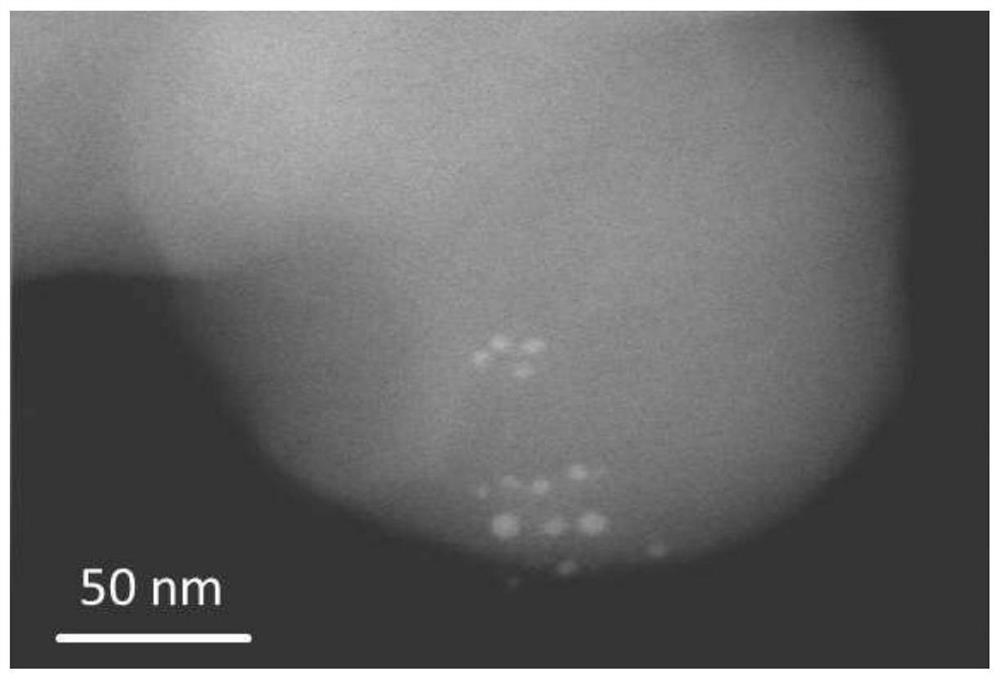

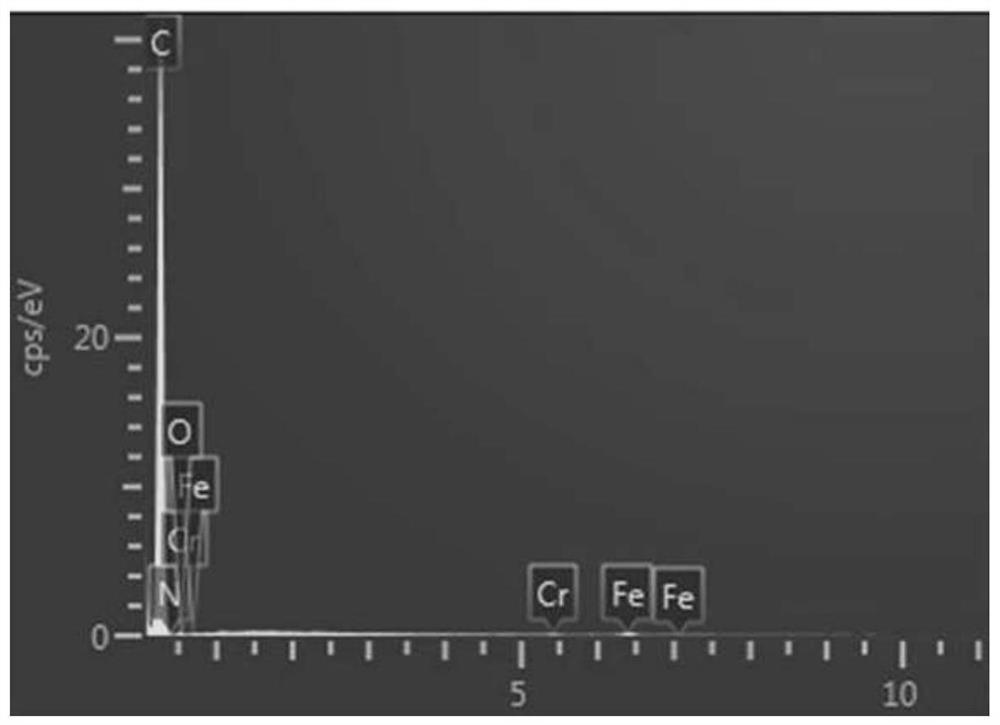

[0035] Put the corundum boat with the transition metal iron chromium into the tube furnace, heat it under the protection of argon under normal pressure for 1h, take out the sample in the corundum boat after cooling to room temperature, and the energy spectrum EDS analysis shows that the obtained asphaltenyl active transition The contents of the metal catalysts iron and chromium were 1.15 and 0.29 wt.%, respectively.

Embodiment 2

[0036] Embodiment 2: put the corundum tube into a tube furnace, and under the protection of nitrogen at a flow rate of 0.4L / min, the temperature of the high temperature part of the corundum tube is raised to 1300°C;

[0037] Put the corundum boat with asphaltene into the reaction furnace, stop heating after 1h, and cool the reaction furnace to room temperature under the protection of nitrogen gas;

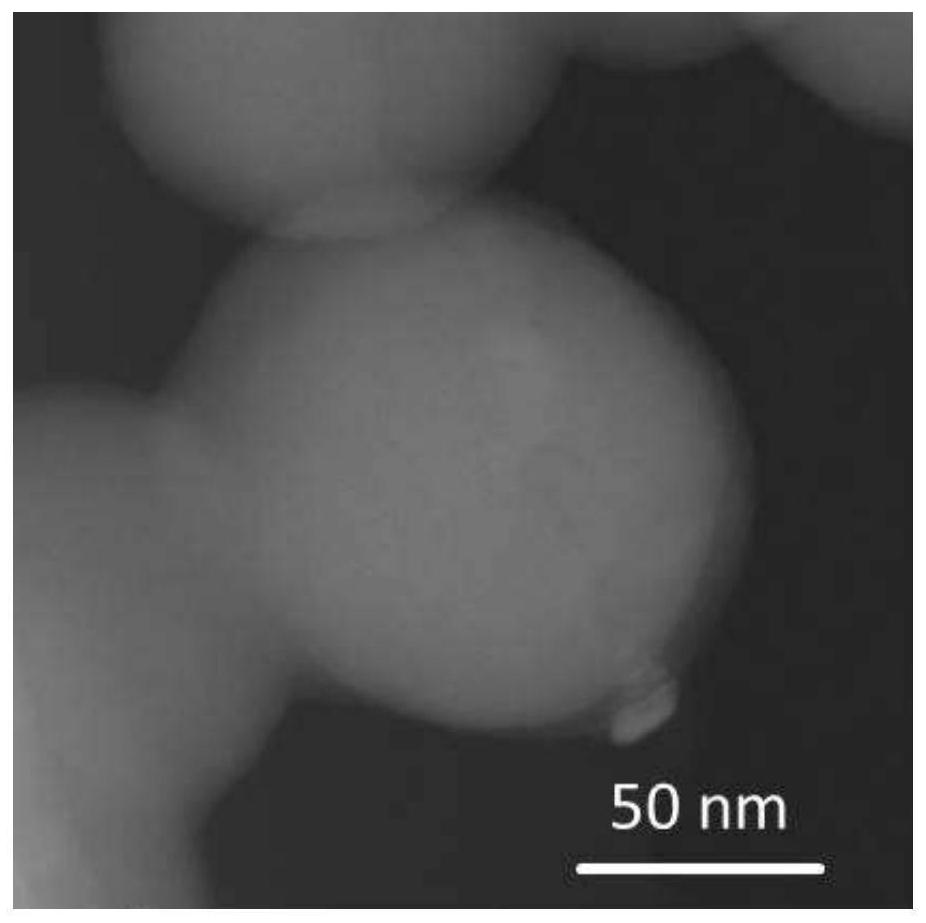

[0038] Put the corundum boat with transition metal iron into the tube furnace, heat it under vacuum for 1 hour, take out the sample in the corundum boat after cooling to room temperature, and analyze the content of asphaltene-based active transition metal catalyst iron by energy spectrum EDS analysis. 0.80wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com